- Messages

- 6,083

- Reaction score

- 13,924

- Location

- UK..

- Arrma RC's

- Infraction

- Mojave EXB

- Outcast 8s

- Outcast EXB

- Talion EXB

- Typhon 6s

Hi everybody,

First up, Big thanks to @Thomas P and @Rich Duperbash for their excellent videos on diffs..???

I thought I would post my findings from my diff rebuild on my V4 Kraton, its only had roughly 5 runs or so, so I thought I would open it up..? so here goes.

I've seen much talk about the shims inside the diff so off I went and watched some vids, the first one I watched @Thomas P and the second was @Rich Duperbash..

They both recommend adding an extra shim on one side of the small gears, so you end up with 1-2 shims.

So here is my diff with pictures and some explanation of what I found and what I decided to do..

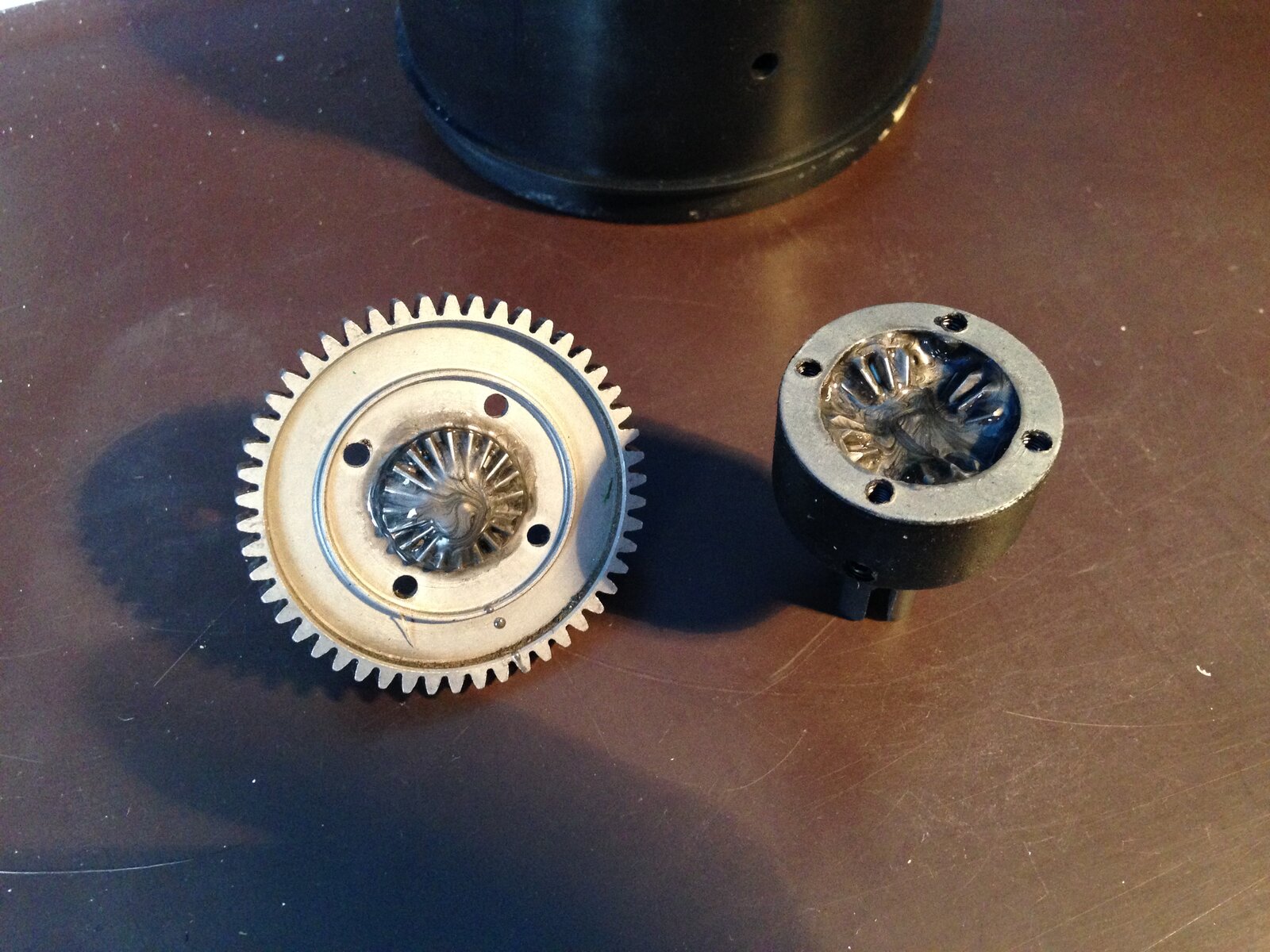

This is when I first opened it, bit confused as it seemed to have a very sticky silvery greasy substance, not silicone oil as I was expecting..?

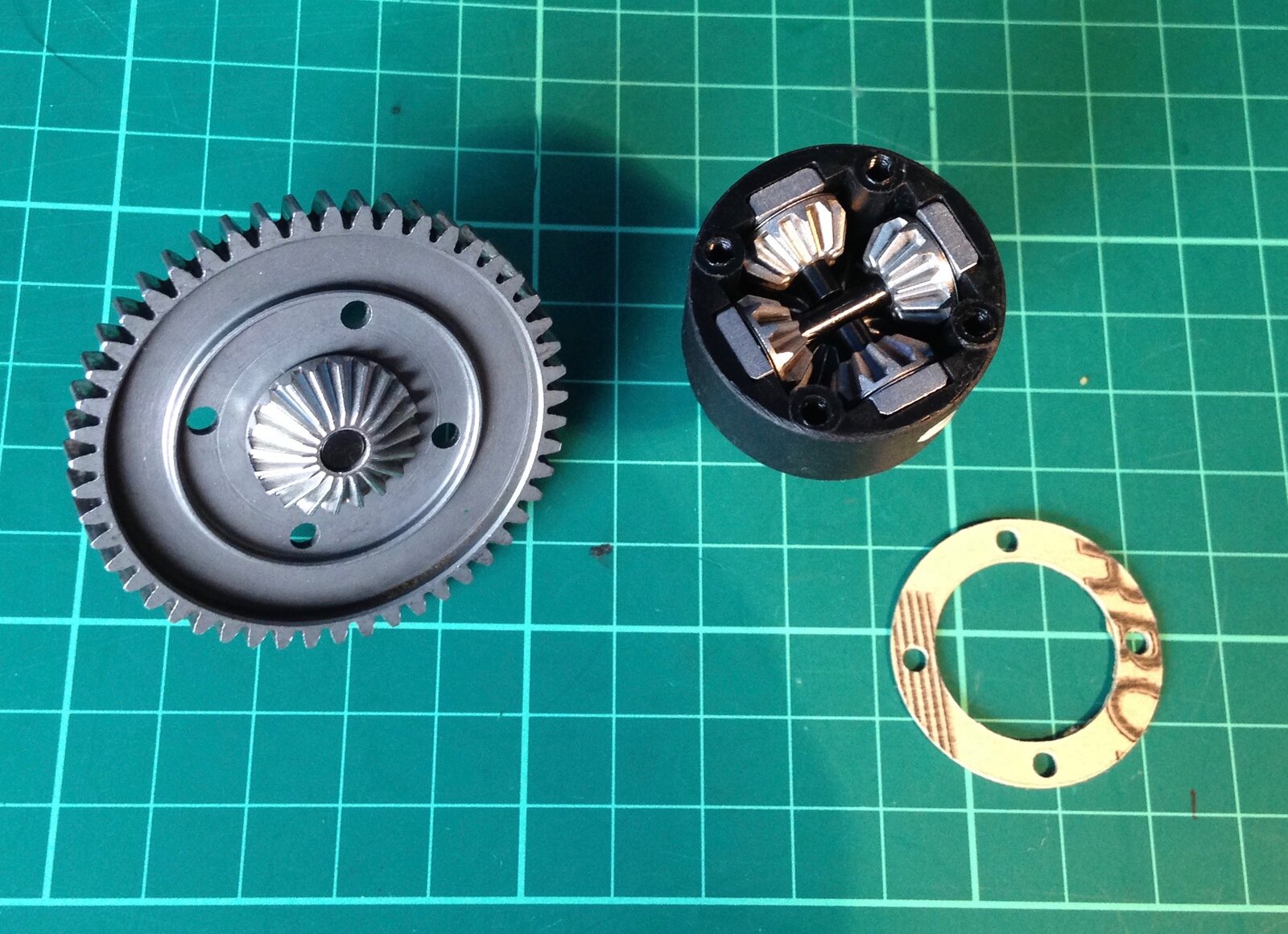

After removing the inner gears

All the parts layed out in a gooey sticky mess..? looks like only one shim per side..?

After cleaning the parts...

Started to measure things and this is where it got interesting...

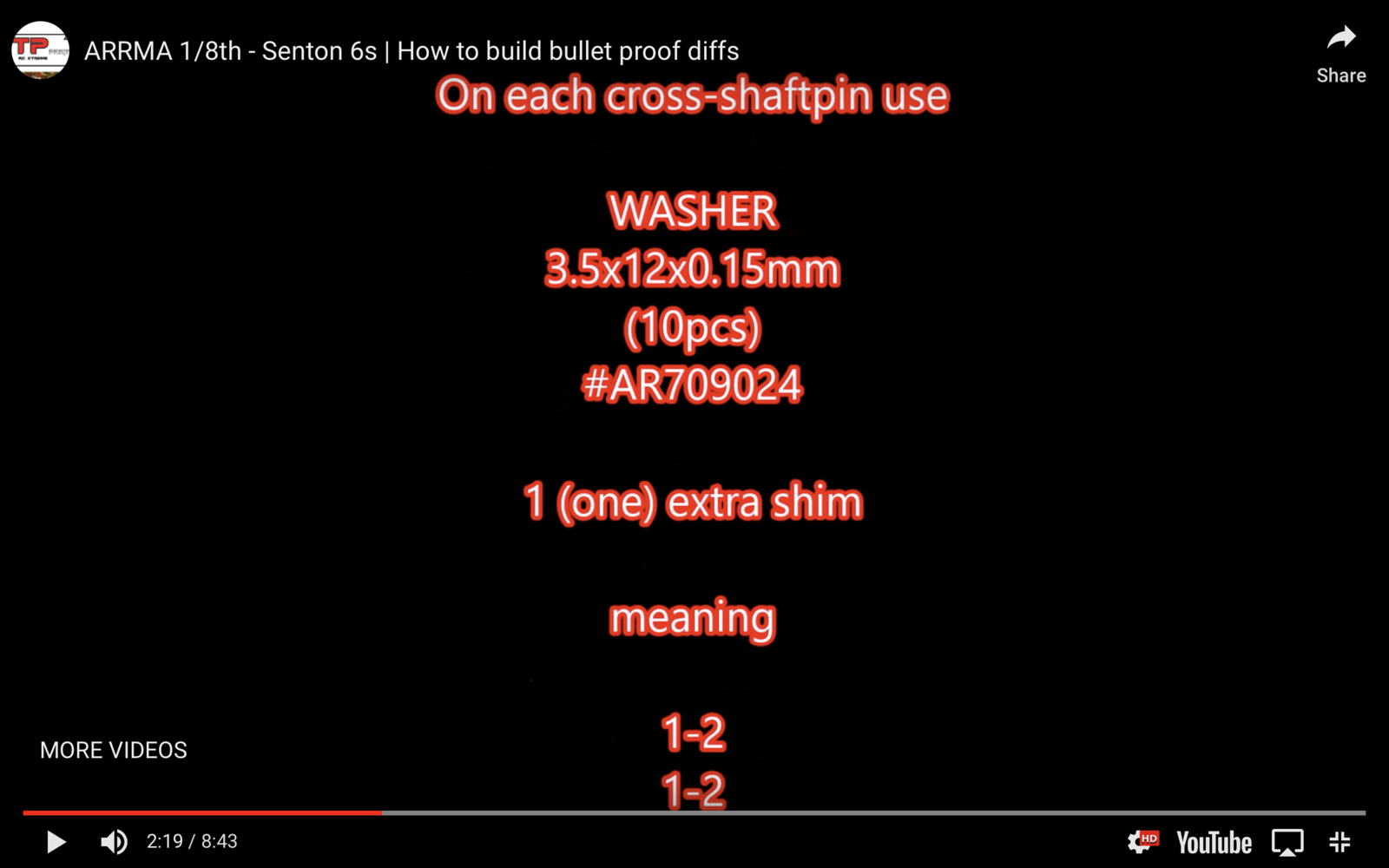

After watching @Thomas P and @Rich Duperbash videos they note add one extra shim, added screenshot from Thomas P vid..??

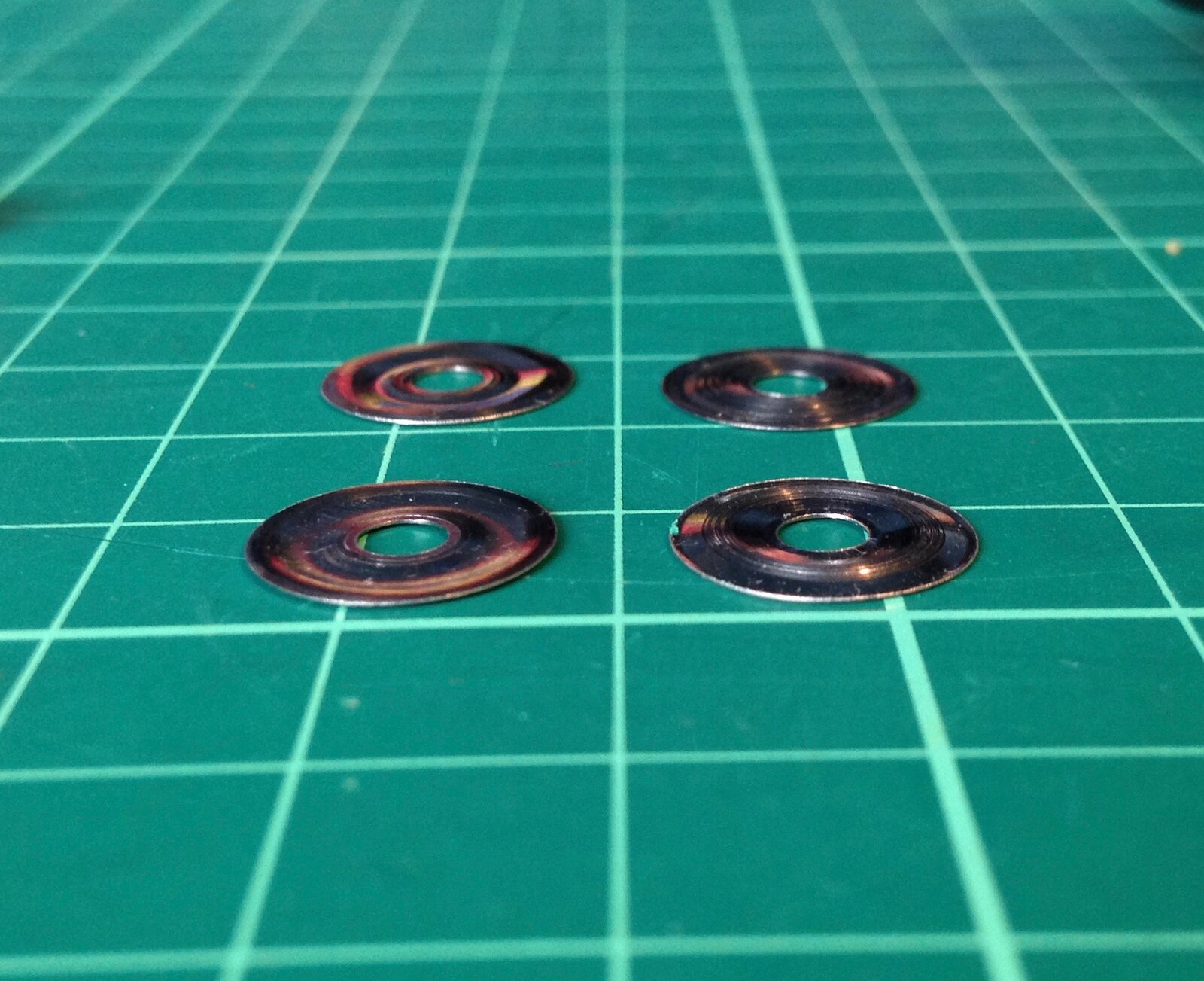

My shims look concave and convex..? although its quite hard to see in my bad photos..?

I'm also quite amazed at how much wear is on the inner plates, considering as I said before this is less than 5-6 runs..!!

I measured my shims and they are between 0.40mm-0.45mm thick..!!

Compare that with @Thomas P 0.15mm thick, so if I had used his method I would be under shimmed by quite a large amount..!!

His video is great at showing you how to rebuild the diffs, this post is not to complain about his setup, far from it.. It's to show how important it is to measure your own stuff..!! and just use youtube for advice, tips and help..!!??

This is the first Arrma diff I've worked on, not my first ever diff...

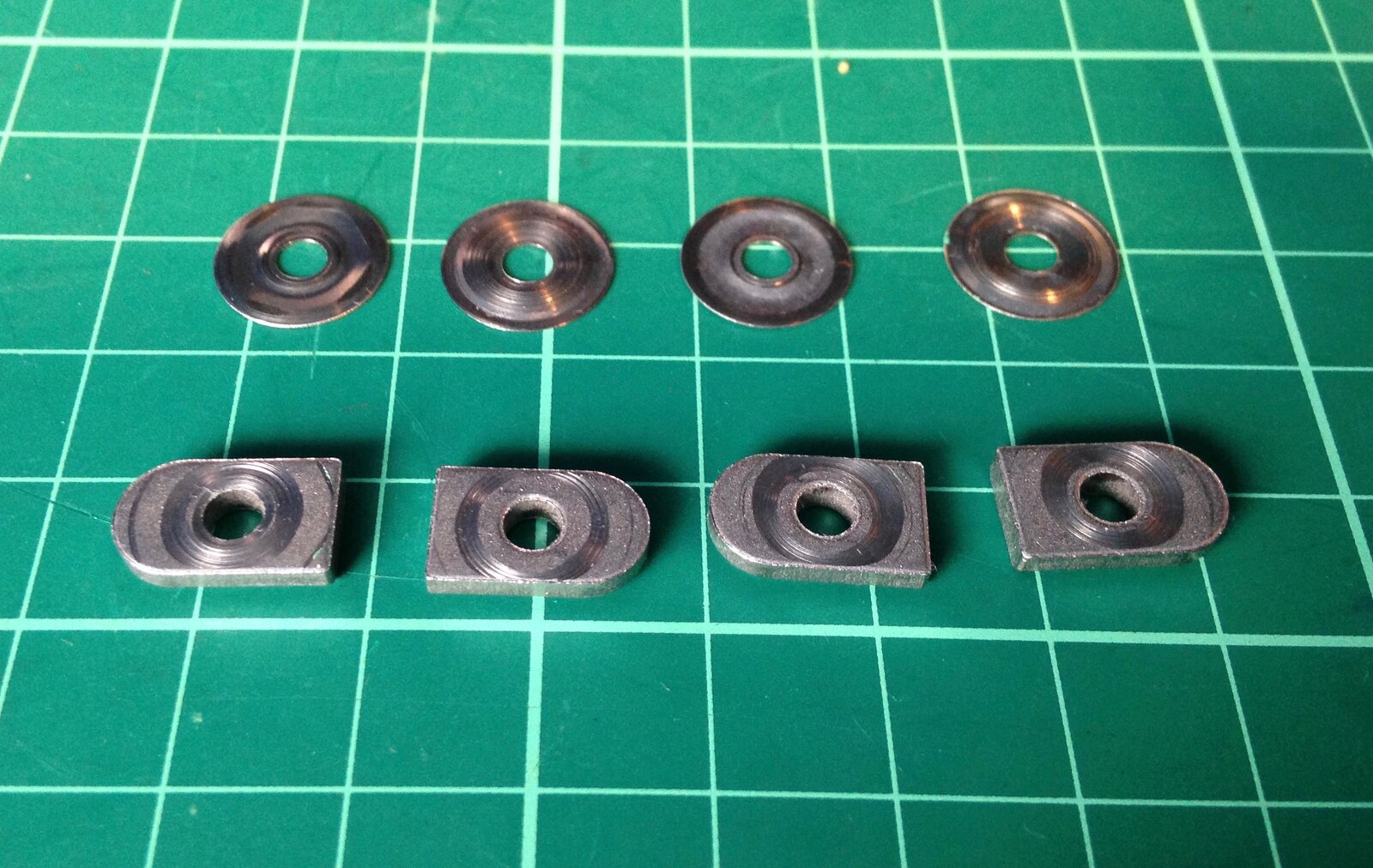

All cleaned and ready to put back together?

I didn't fit the big 8x15mm shim under the planet gear as I forgot to buy them..? this just shows what was inside as standard..

As you can see I used Green Slime to lube the o-ring and the outdrive cup shaft also some extra under the shim..?

All test fitted dry with a Tekjo gasket ( Thx Steph ?? ), will be filled with 500k...

At this stage I'm wondering how much has changed in the manufacturing of these diff houses as my shims are huge thickness compared to others I've seen on here..!!

Are these concave/convex shims normal or have I just got a duff batch or a totally new design..?

What amount of play is allowed..???

Everything seems nice and snug fitting at this stage in its dry state..

I will put it all back together and test it before I do the front and rear, because if this one goes wrong at least its the easiest to remove and start again..??

So there you go, I hope this helps people out...??

First up, Big thanks to @Thomas P and @Rich Duperbash for their excellent videos on diffs..???

I thought I would post my findings from my diff rebuild on my V4 Kraton, its only had roughly 5 runs or so, so I thought I would open it up..? so here goes.

I've seen much talk about the shims inside the diff so off I went and watched some vids, the first one I watched @Thomas P and the second was @Rich Duperbash..

They both recommend adding an extra shim on one side of the small gears, so you end up with 1-2 shims.

So here is my diff with pictures and some explanation of what I found and what I decided to do..

This is when I first opened it, bit confused as it seemed to have a very sticky silvery greasy substance, not silicone oil as I was expecting..?

After removing the inner gears

All the parts layed out in a gooey sticky mess..? looks like only one shim per side..?

After cleaning the parts...

Started to measure things and this is where it got interesting...

After watching @Thomas P and @Rich Duperbash videos they note add one extra shim, added screenshot from Thomas P vid..??

My shims look concave and convex..? although its quite hard to see in my bad photos..?

I'm also quite amazed at how much wear is on the inner plates, considering as I said before this is less than 5-6 runs..!!

I measured my shims and they are between 0.40mm-0.45mm thick..!!

Compare that with @Thomas P 0.15mm thick, so if I had used his method I would be under shimmed by quite a large amount..!!

His video is great at showing you how to rebuild the diffs, this post is not to complain about his setup, far from it.. It's to show how important it is to measure your own stuff..!! and just use youtube for advice, tips and help..!!??

This is the first Arrma diff I've worked on, not my first ever diff...

All cleaned and ready to put back together?

I didn't fit the big 8x15mm shim under the planet gear as I forgot to buy them..? this just shows what was inside as standard..

As you can see I used Green Slime to lube the o-ring and the outdrive cup shaft also some extra under the shim..?

All test fitted dry with a Tekjo gasket ( Thx Steph ?? ), will be filled with 500k...

At this stage I'm wondering how much has changed in the manufacturing of these diff houses as my shims are huge thickness compared to others I've seen on here..!!

Are these concave/convex shims normal or have I just got a duff batch or a totally new design..?

What amount of play is allowed..???

Everything seems nice and snug fitting at this stage in its dry state..

I will put it all back together and test it before I do the front and rear, because if this one goes wrong at least its the easiest to remove and start again..??

So there you go, I hope this helps people out...??