CRF81

Fairly New Member

- Messages

- 11

- Reaction score

- 17

Hey guys trying to find 8S axles that last longer then a few runs. We all know the stockers break the pins at the diff. They also occasionally bend on bad landings. Well not that bad if it's not a airplane hitting wings on touch down.... I do great with stockers until the pin breaks under torque. Yes if I land on all left or right side I will at times bend them but not always. I was waiting like all of us to try the M2C solution. Well they fail as well... Honestly guys I give the straight up truth and I'm not a promoter of any sort but the M2C were as bad as stock! Save that big money and have several stock ones on hand when they do break. The M2C broke apart not even hard bashing. I was drifting my rig and doing power wheelies just messing around and I heard the dreaded clicking noise. Turns out on my last blast in a turn by myself I heard the axle fly out. I'm running a 1100 kv castle motor so it's good but no monster. Anyways guys my goal here is to talk about what works and what does not. I will do so respectfully and I will most definitely shame my own bad driving faults etc. But just the heads up don't waste money on M2C CVD axles! I'm posting this because I'm not alone my driving partner also broke his just messing around. M2C said we are doing on throttle landings etc breaking these and did not offer support except to purchase these high dollar CVDs again. I'm bummed because M2C has not let me down but these CVDs are junk. 1mm shorter to stop the bending well I can get that tiny amount with my grinder. Bottom line don't waste your money stock is better. I bought GPM CVD anyone try those yet?

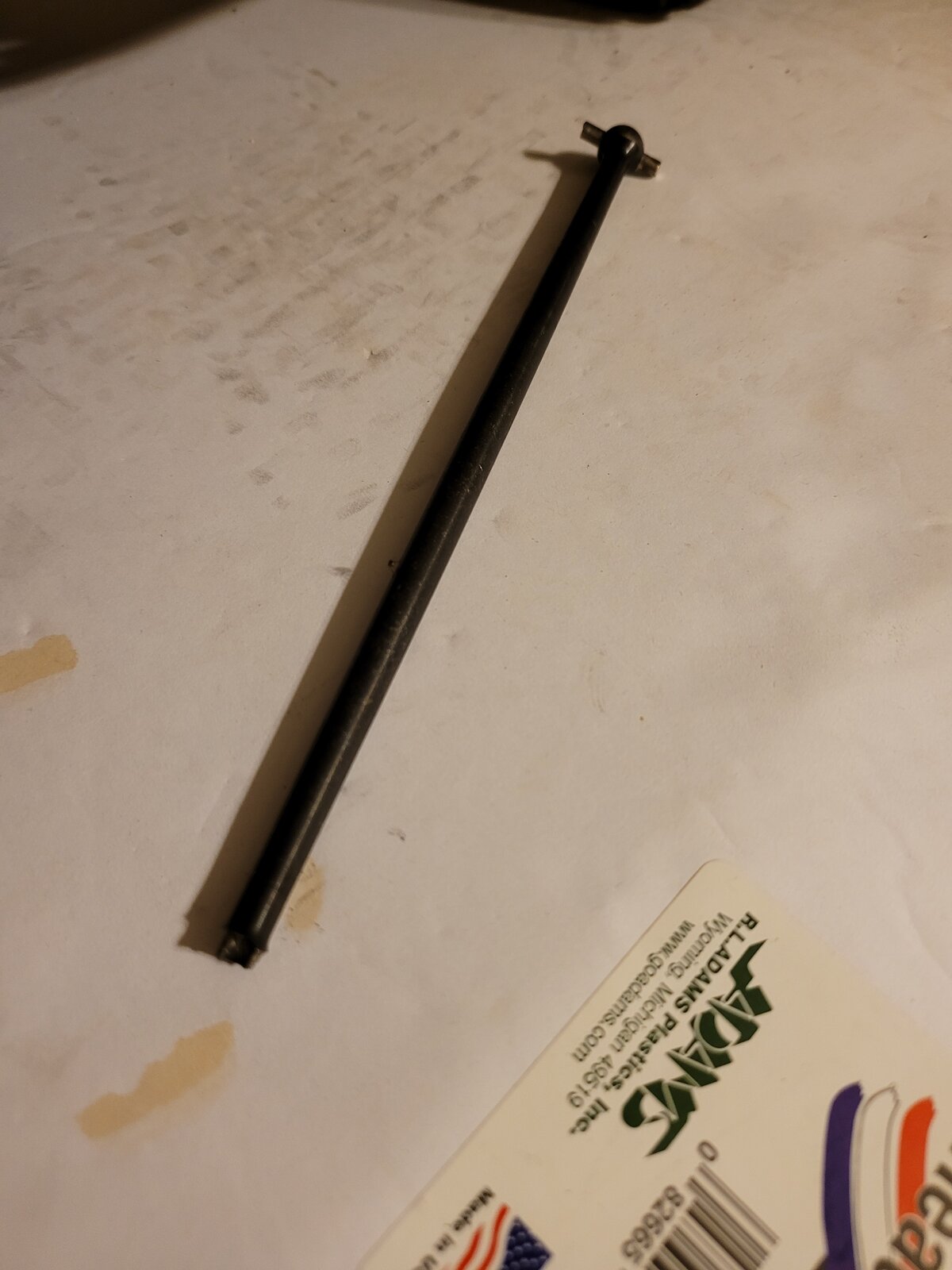

Check my pic of M2C breaking clean off not bent. This happens on the hub side now. My friends Kraton did the exact same and has video of it. We will post on YouTube soon of this happening. Freaking embarrassing

Check my pic of M2C breaking clean off not bent. This happens on the hub side now. My friends Kraton did the exact same and has video of it. We will post on YouTube soon of this happening. Freaking embarrassing