Zip ties bout as good as duct tape. Imho. LolI see you've wasted no time in getting the tail gate opening started. It's my biggest pet peeve about the Granite body. Mine is currently stitched with twist ties and holding up well.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Granite My V3 Granite BLX is here! I'm back where I started with Arrma 😁

- Thread starter Armarookie43

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #42

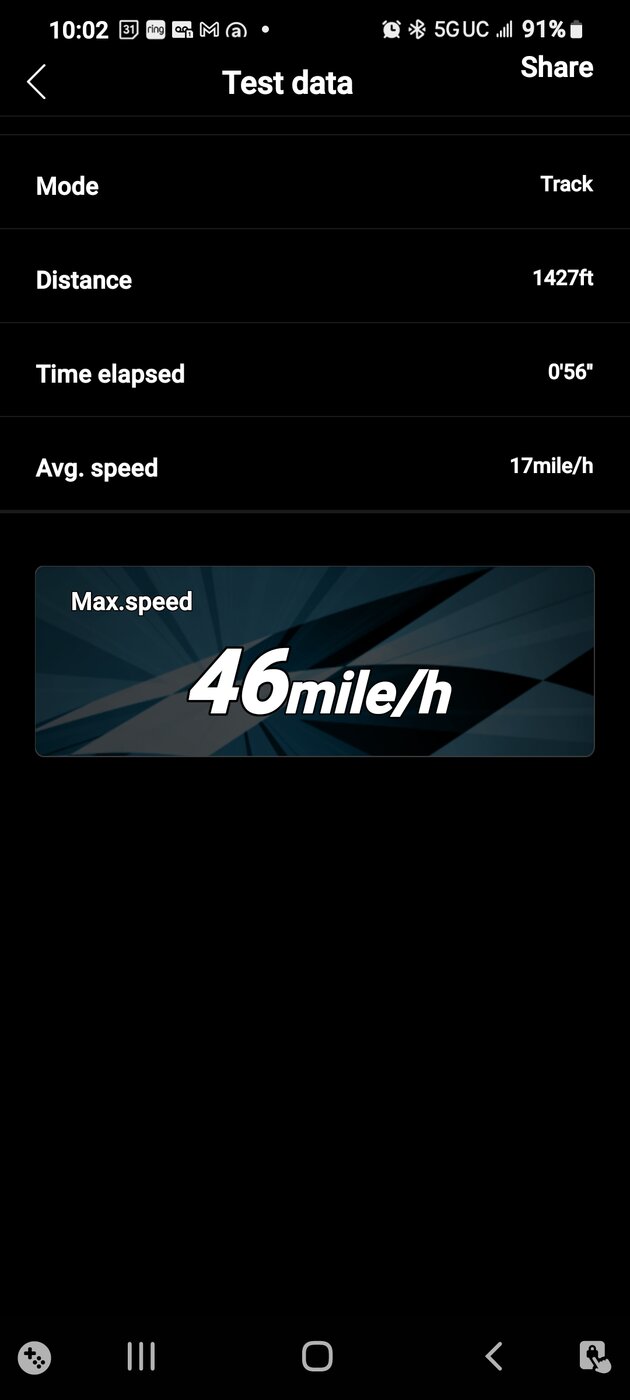

Got the Granite all fixed up. New chassis in and I decided to put a HR servo and arm on it. New steering servo is in. I decided to try out a 20t pinion with dual fans on the motor. I got 46MPH on pavement. Not bad but I need more. I think that I'll try a 22t pinion now or 23t. I'm shooting for 50mph on pavement at least.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #43

I decided to go back to stock gearing and the stock motor/ESC. It's just not worth the extra weight and trouble of the Felony esc/motor. Plus, it's still slower than a stock Granite on 3s. I decided to keep upgrading my Granite with HR servo saver and front hubs. I installed a new slipper clutch since I damaged the previous one (broke the center bolt and contaminated the slipper pads with lubricant. I had put grease on the spur gear and pinion. BAD dumb idea). I just want this thing to survive moderate jumps. I also got a cheap ebay body off ebay but the holes for the body posts were in the wrong place so I had to make my own. I also bought the parts for the front diff and output drive from HR like I did in the rear diff. Yeah I've lost my mind with upgrades, but I'm used to dumping loads of cash on upgrades on my other RC vehicles

What does this thing weight? My girls' Vorteks are incredibly tough and they are almost totally stock. I suspect those wheels and tires are significantly heavier than stock as well... are they? What are you running for a pinion?

My favourite upgrades for 6S rigs are BasherQueen carbon bits, but those are unnecessary for 3S trucks. The more weight you add, the more it will break. You upgrade to make it tougher but it makes it heavier and that leads to more breakage.... you are better off making it lighter. The best upgrade I ever did to my Notorious was to go to the Backflip LP tires for a bit less weight and lower rotating mass. Then the BasherQueen towers, brace, and other bits dropped a nice extra bit of weight.

My favourite upgrades for 6S rigs are BasherQueen carbon bits, but those are unnecessary for 3S trucks. The more weight you add, the more it will break. You upgrade to make it tougher but it makes it heavier and that leads to more breakage.... you are better off making it lighter. The best upgrade I ever did to my Notorious was to go to the Backflip LP tires for a bit less weight and lower rotating mass. Then the BasherQueen towers, brace, and other bits dropped a nice extra bit of weight.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #45

The stock tires and the tires I'm using feel about the same weight. But I do have aluminum front hubs, aluminum driveshafts, aluminum M2C motor mount, aluminum differentials in the rear and soon now in the front. So yeah, I probably made things worse. Oh yeah, aluminum servos saver and aluminum bell crank. I forgot t mention the aluminum M2C 17mm hex adapters and Mojave shocks all aroundWhat does this thing weight? My girls' Vorteks are incredibly tough and they are almost totally stock. I suspect those wheels and tires are significantly heavier than stock as well... are they? What are you running for a pinion?

My favourite upgrades for 6S rigs are BasherQueen carbon bits, but those are unnecessary for 3S trucks. The more weight you add, the more it will break. You upgrade to make it tougher but it makes it heavier and that leads to more breakage.... you are better off making it lighter. The best upgrade I ever did to my Notorious was to go to the Backflip LP tires for a bit less weight and lower rotating mass. Then the BasherQueen towers, brace, and other bits dropped a nice extra bit of weight.

Throw that beast on a scale is the best thing to do - then we can compare to stock.The stock tires and the tires I'm using feel about the same weight. But I do have aluminum front hubs, aluminum driveshafts, aluminum M2C motor mount, aluminum differentials in the rear and soon now in the front. So yeah, I probably made things worse. Oh yeah, aluminum servos saver and aluminum bell crank. I forgot t mention the aluminum M2C 17mm hex adapters and Mojave shocks all around

I learned that lesson very early. Had a trashy Redcat early on and it broke a lot. So I upgrade a bunch of parts to metal... and then it would pretty much just explode every time I ran it. The EXC Amp MT my son and I built first we upgraded to brushless but otherwise totally stock... and it is extremely tough. I know a guy with an Amp Crush who "upgraded" to a bunch of metal parts and it breaks every time he runs it. Which now he almost never does.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #47

It depends on the vehicle too . I've upgraded my X-Maxx, Outcast 8s and EXB K8S with some aluminum parts and it has made them better. The plastic parts on those rigs are much thicker though. And you are right. I should weigh it and see where I'm at. Also, I've upgraded some stuff with a aluminum on my V2 Maxx, and that truck is more durable now too. So yeah.Throw that beast on a scale is the best thing to do - then we can compare to stock.

I learned that lesson very early. Had a trashy Redcat early on and it broke a lot. So I upgrade a bunch of parts to metal... and then it would pretty much just explode every time I ran it. The EXC Amp MT my son and I built first we upgraded to brushless but otherwise totally stock... and it is extremely tough. I know a guy with an Amp Crush who "upgraded" to a bunch of metal parts and it breaks every time he runs it. Which now he almost never does.

A nice purchase and well worth every Dollar imo. It does have issues though. You can find out about the problems here. A hint is that probably the servo will go first, especially if you're a basher. Running your clutch too tight probably will blow your drive shafts.

razorrc has a couple of videos on his channel about what to do before running. Be sure to check them out. They can save you some trouble.

I just watched a few of his videos. Very helpful.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #49

That's how my issues started. By tightening the slipper clutch too hard. It went downhill from there with all kinds of upgrades. Oh well.I just watched a few of his videos. Very helpful.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #50

Once I get the stock motor, esc, and gearing squared away , and install a new slipper clutch assembly (completely new from the 4s line), I'll try to run this thing again. I'll try to me as nice as possible with it. I'll admit that most of my issues have been user error indeed. I remember it was pretty durable when it was brand new completely stock. After a few hard bashes, I did bend the motor mount and a couple of the shock shafts. Then the plastic spur gear stripped (I installed a metal spur gear from the 4s line). Then the slipper clutch got loose. After that I tightened it too much and started breaking driveshafts. That's when I went with the upgrades.

New slipper clutch is great now the key is set It properly. Make sure it will actually slip when it should. Too loose is better than too tight. Too loose and you tighten it. Too tight and you break stuff.Once I get the stock motor, esc, and gearing squared away , and install a new slipper clutch assembly (completely new from the 4s line), I'll try to run this thing again. I'll try to me as nice as possible with it. I'll admit that most of my issues have been user error indeed. I remember it was pretty durable when it was brand new completely stock. After a few hard bashes, I did bend the motor mount and a couple of the shock shafts. Then the plastic spur gear stripped (I installed a metal spur gear from the 4s line). Then the slipper clutch got loose. After that I tightened it too much and started breaking driveshafts. That's when I went with the upgrades.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #52

I have all metal driveshafts now and soon the front differential will also be all metal. So I'm thinking that the slipper itself would break if I set it too tight this timeNew slipper clutch is great now the key is set It properly. Make sure it will actually slip when it should. Too loose is better than too tight. Too loose and you tighten it. Too tight and you break stuff.

More likely you will destroy a ring and pinion or diff internals.I have all metal driveshafts now and soon the front differential will also be all metal. So I'm thinking that the slipper itself would break if I set it too tight this time

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #54

Maybe the internals. I doubt the ring and pinion. Those are very beefy. Anyways, I use the roll method to adjust the slipper clutch like you are supposed toMore likely you will destroy a ring and pinion or diff internals.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #56

Thanks. It's going to be quite the little beast once I put it together again. I'm just waiting on the bearings for the slipper assembly since they were worn out badly.nice rig you got there brother

RCs&V8s

Member

- Messages

- 41

- Reaction score

- 31

- Arrma RC's

- Granite

Cool black body!

I enjoy my Granite. Add the wing mount and a wing to save your tailgate.....I did, it works! My tailgate still looks brand new.

Ah yes,...The internal struggle to resist replacing things with metal,...I'm there as well. So far I've replaced plastic with plastic as Arrma intended but I get it. I try to be very selective about adding metal, (ball joints maybe?) The stock plastic is light and flexible and when a plastic piece does break sometimes it's good that it gave way to save other parts.

I haven't blown a plastic driveshaft yet even with the longer RPM Typhon A-Arms. Been about 10 packs.

I enjoy my Granite. Add the wing mount and a wing to save your tailgate.....I did, it works! My tailgate still looks brand new.

Ah yes,...The internal struggle to resist replacing things with metal,...I'm there as well. So far I've replaced plastic with plastic as Arrma intended but I get it. I try to be very selective about adding metal, (ball joints maybe?) The stock plastic is light and flexible and when a plastic piece does break sometimes it's good that it gave way to save other parts.

I haven't blown a plastic driveshaft yet even with the longer RPM Typhon A-Arms. Been about 10 packs.

Highly recommend you seal up the power module so you don't get so much fine dust in there.Thanks. It's going to be quite the little beast once I put it together again. I'm just waiting on the bearings for the slipper assembly since they were worn out badly.

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #59

It survived the first few jumps! I did break a front arm, but what's funny is that I was not even jumping. I hit a damn small rocknice rig you got there brother

- Messages

- 4,710

- Reaction score

- 6,521

- Location

- San Antonio TX

- Arrma RC's

- Felony

- Granite

- Infraction

- Kraton 8S

- Mojave EXB

- Outcast 8s

- Typhon 6s

- Thread starter

- #60

My upgraded disaster continues. The rear diff got destroyed internally and externally. Maybe because the end of the GPM driveshaft broke off?? That's another failure. Oh well. Going back to stock rear diff and input gear. I'll probably re use the gpm aluminum yoke set. I'm going to try one RCAWD drive shafts in the rear , but I've heard bad things about RCAWD stuff. If those don't work, I'll probably go back to stock driveshafts. I'm not giving up. I just have to get rid of some of these unnecessary upgrades that were expensive and NOT WORTH IT. If only I could have adjusted my slipper properly instead of choosing the upgrade rabbit hole

Last edited:

Similar threads

- Replies

- 10

- Views

- 824

- Replies

- 3

- Views

- 185