- Messages

- 1,802

- Reaction score

- 3,288

- Location

- Tennessee

- Arrma RC's

- Felony

- Infraction

- Limitless

- Kraton EXB

- Mojave

- Outcast EXB

- Senton 6s

- Vendetta

- Thread starter

- #41

Orientation is correct and yes always use 100% infill on all RC parts no exceptions. I'd do a bit thicker wall. Glad to hear your other held up. Prolly smacked something on this one im guessing and why it broke.That’s a fair question, but hard to answer haha. It was only one round of practice and one round of qualifying. I don’t remember any major crash but there were a few bumps and side brushes for sure. The piece only fell off when I was inspecting the Ackerman back home.

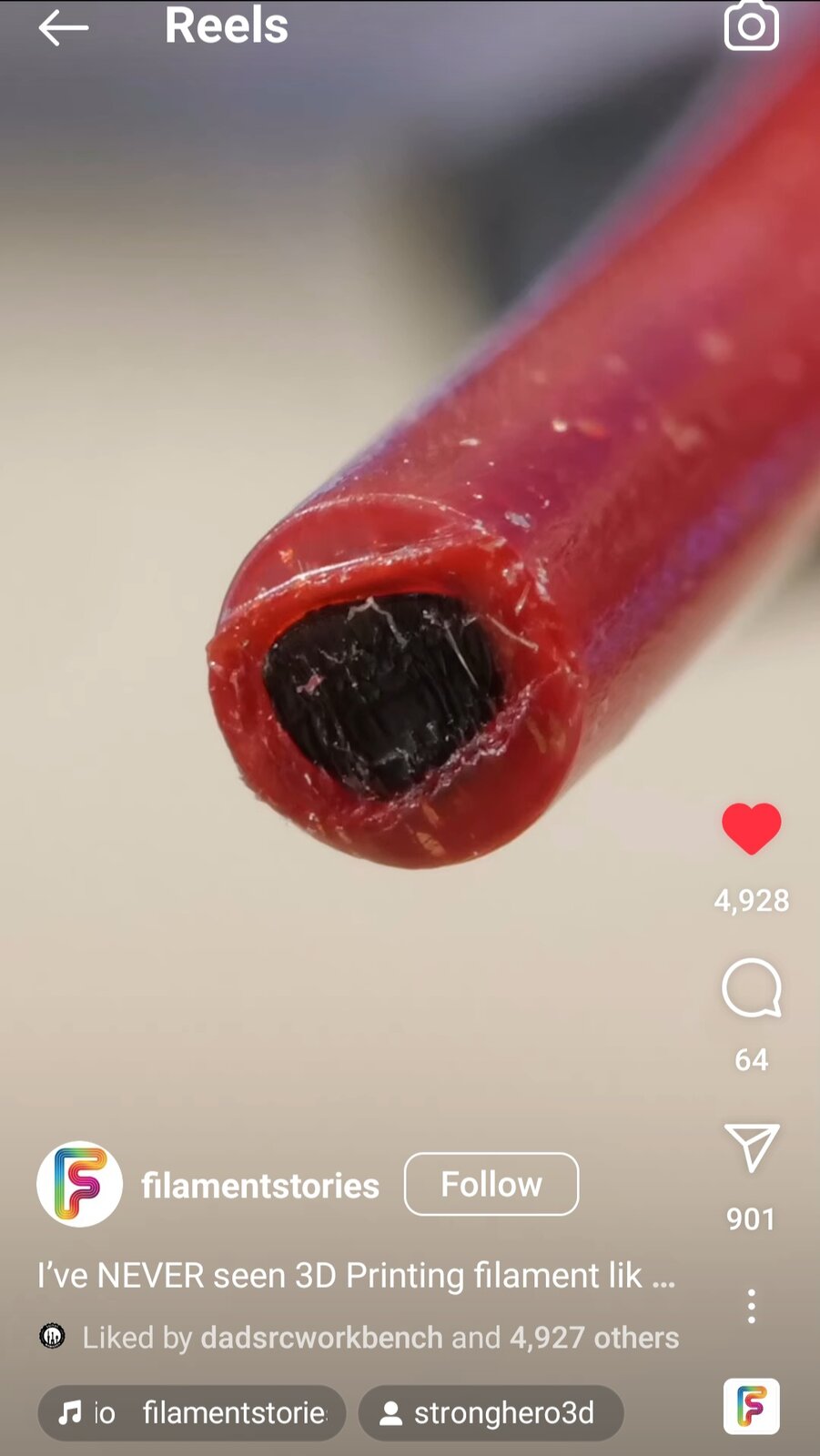

Some close ups of the break, sheared off.

View attachment 354799

View attachment 354800

My main car that did two qualifying rounds and the main has the same part, and it’s still intact as far as I know. I should probably check.

Thanks for the wire/divot/rod idea! Will try that if I continue to see breakage.

Btw is my print orientation okay? I printed it the way I show on the photos above. I set wall thickness to 3mm and infill to 100%.