Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Granite Power Module Screws Threadlock?

- Thread starter MrLimey

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 2,923

- Reaction score

- 6,295

- Location

- Potsdam, New York, (You-S-Eh)

- Arrma RC's

- Infraction

- Kraton 8S

- Kraton 6s

- Mojave

- Mojave EXB

- Outcast 4s

- Senton 3s

- Talion

- Typhon 3s

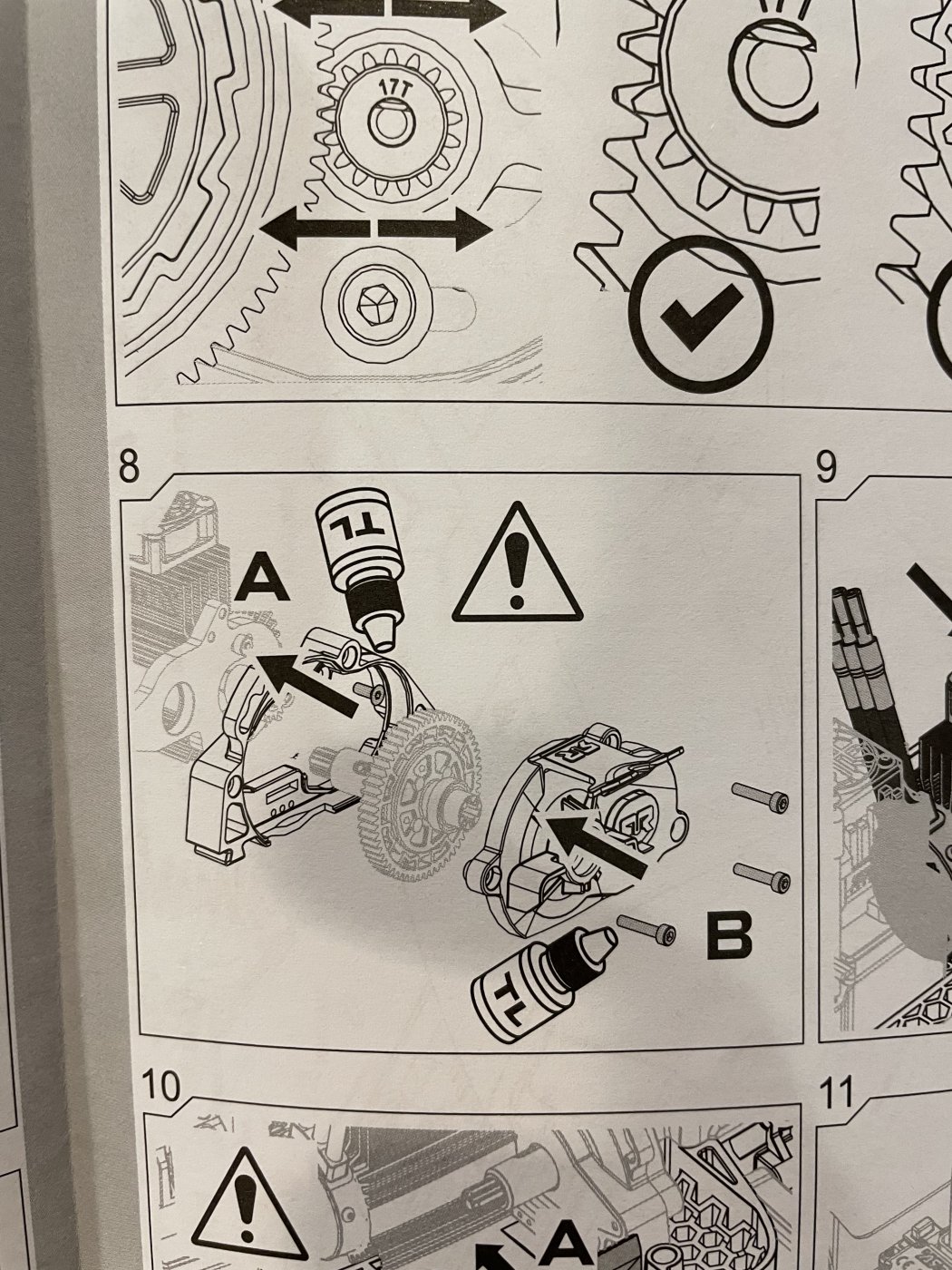

I normally put a little locktite blue on them. IMHOCan anyone tell me if the power module cover screws get thread lock? It looks like they screw thru into the metal motor mount. And they appear to have white colored thread lock on them from the factory. So I think so but wanted to check. Thanks!View attachment 228557

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

+1

Metal to metal Fasteners are always Blue TL'ed.

Clean the screws well before reapplying TL.

TL Must Cure for the better part of a day before use. Not cured , it can even loosen quicker.

Metal to metal Fasteners are always Blue TL'ed.

Clean the screws well before reapplying TL.

TL Must Cure for the better part of a day before use. Not cured , it can even loosen quicker.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

**

Use alcohol or any cleaner. Even Windex Cleaner or similar is better than nothing. A small Brass wire brush I might use at times. Sometimes the Screws become toast at some point . Constant re-application of TL ruins the threads. What I noticed. They can strip.

Ideally you want an automotive Brake Cleaner Solvent spray of sorts. Best.

Old TL is stubborn to remove. Sometimes not getting all of it off.

I use Loctite Blue 243. TL. It is Oil and dirt friendly.

Some guys actually use a Torch to Burn it off the screws.

Use alcohol or any cleaner. Even Windex Cleaner or similar is better than nothing. A small Brass wire brush I might use at times. Sometimes the Screws become toast at some point . Constant re-application of TL ruins the threads. What I noticed. They can strip.

Ideally you want an automotive Brake Cleaner Solvent spray of sorts. Best.

Old TL is stubborn to remove. Sometimes not getting all of it off.

I use Loctite Blue 243. TL. It is Oil and dirt friendly.

Some guys actually use a Torch to Burn it off the screws.

Last edited:

- Thread starter

- #6

Thanks. What's weird, is I have watched tons of videos about checking the gear mesh, and cleaning out inside the motor module regularly (why I took it apart today) but no mention of using threadlock to reassemble so thanks for the help. It is definitely metal to metal screwing into the motor mount so it definitely seems required.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

That is not a very critical needed place for TL in general. IMO.

Not a 4x4 guy myself , so I don't know best......... Others may chime in regarding.

But if definitely Metal to metal, the tiniest drop of TL on the bottom threads is all you need, TBH.

Not a 4x4 guy myself , so I don't know best......... Others may chime in regarding.

But if definitely Metal to metal, the tiniest drop of TL on the bottom threads is all you need, TBH.

Hector_Fisher

Very Active Member

In my opinion, you don't need it. The only reason I can see needing thread lock is for metal to metal contact with a metal fastener. In such case, you won't be able to apply enough torque to those small fasteners (without stripping) to keep load on the thread and keep the fasteners in place during vibrations and stresses. Anytime you have a compressible involved (gasket, spring, etc.--in this case, a plastic power module), the elasticity of the compressible creates constant pressure on the threads when you torque the screws; this prevents screws from working their way loose during vibrations and stress.

FWIW, mine came with some black gunk on the threads that I promptly removed. Taken the power module apart and put back together several dozen times on a few trucks and it's always held together with no thread lock used.

FWIW, mine came with some black gunk on the threads that I promptly removed. Taken the power module apart and put back together several dozen times on a few trucks and it's always held together with no thread lock used.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

^^^ That's what I figured.

After owning my Arrma outcast 6s for the past 2 weeks, almost everything has come loose and needed to be threadlocked. Even the screws that hold the motor together.

Make sure you let it cure!! The most important step to threadlocking anything! Even in the automotive world. Seen way too many new mechanics threadlock stuff and the bolts come loose faster if not cured.

Make sure you let it cure!! The most important step to threadlocking anything! Even in the automotive world. Seen way too many new mechanics threadlock stuff and the bolts come loose faster if not cured.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

^^^ You are right. Anyone who has worked in Automotive repair knows this. Wet, Un-cured TL remains almost as a lubricant and loosens faster.

Just the opposite of what you want.

TL Needs to cure.

I use Blue 243, not 242, Loctite Brand for my RC rigs. Red only for my scale Cars, large hardware. Applying "Less" is More". And "More" is Less.

TL is very expensive. Better to buy a 50ML large bottle over a small Tube. Lasts for years. Bottle dispenses better, less waste vs. a small tube.

https://www.henkel-adhesives.com/us...stry-insights/how-to-apply-threadlockers.html

Edited.

Just the opposite of what you want.

TL Needs to cure.

I use Blue 243, not 242, Loctite Brand for my RC rigs. Red only for my scale Cars, large hardware. Applying "Less" is More". And "More" is Less.

TL is very expensive. Better to buy a 50ML large bottle over a small Tube. Lasts for years. Bottle dispenses better, less waste vs. a small tube.

https://www.henkel-adhesives.com/us...stry-insights/how-to-apply-threadlockers.html

Edited.

Last edited:

Hector_Fisher

Very Active Member

If all three components (piece 1, piece 2, fasteners) are metal, then yes thread lock is absolutely necessary. If one of those is plastic, my answer would be: it depends, but likely no. And yeah a large majority of the fastened connections on the 6s stuff are all metal, quite different than the 3s line where almost all connections involve some sort of plastic component.After owning my Arrma outcast 6s for the past 2 weeks, almost everything has come loose and needed to be threadlocked. Even the screws that hold the motor together.

Make sure you let it cure!! The most important step to threadlocking anything! Even in the automotive world. Seen way too many new mechanics threadlock stuff and the bolts come loose faster if not cured.

You can usually tell if thread lock is needed by gauging how much continued twisting is possible after the nut/bolt initially seats. If you can keep screwing for a turn or two and the turning becomes more and more difficult (building torque), then you should be fine. If it feels like you "hit a wall" and you suddenly have to start giving lots of torque, then it likely needs thread lock. Just my two cents.

For real though, the temptation to go out and drive a truck you just repaired is strong!!!! When you should be waiting for that TL to cure.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,886

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

If I am out in th field bashing, and do a repair that needs TL, I won't use any TL at all, if I want to continue bashing. The Screw/nut will remain tighter than if using wet uncured TL. For instance, changing a Pinion out. I won't use TL on the Pinion Grub screw and motor mount slider screws. Better left dry of TL.

Air has to release from the TL in the threads for it to cure. Only Time will do this. No way to accelerate this. 24 hours.

Air has to release from the TL in the threads for it to cure. Only Time will do this. No way to accelerate this. 24 hours.

- Messages

- 5,364

- Reaction score

- 8,339

- Arrma RC's

- Felony

- Kraton EXB

- Senton 3s

I've never used it on mine.. its really just a case/cover and I think since the 2 plastic pieces are sandwiched, it doesn't require much "torque" to properly seat it to the motor mount!? I guess u could use it if u wanted too!?

This is very true as well, if your screws come out of plastic often, what you truly need to do is either use larger hardware to cut into the plastic and create a bond, or replace the part truly.If all three components (piece 1, piece 2, fasteners) are metal, then yes thread lock is absolutely necessary. If one of those is plastic, my answer would be: it depends, but likely no. And yeah a large majority of the fastened connections on the 6s stuff are all metal, quite different than the 3s line where almost all connections involve some sort of plastic component.

You can usually tell if thread lock is needed by gauging how much continued twisting is possible after the nut/bolt initially seats. If you can keep screwing for a turn or two and the turning becomes more and more to difficult (building torque), then you should be fine. If it feels like you "hit a wall" and you suddenly have to start giving lots of torque, then it likely needs thread lock. Just my two cents.

For real though, the temptation to go out and drive a truck you just repaired is strong!!!! When you should be waiting for that TL to cure.

- Messages

- 5,364

- Reaction score

- 8,339

- Arrma RC's

- Felony

- Kraton EXB

- Senton 3s

Yep.. doesn't want you sqeezing and smashing the soft/hollow composite together!The screws did ‘hit a wall’. I don’t think the plastic is threaded and it doesn’t compress much. I

- Messages

- 2,477

- Reaction score

- 2,586

- Arrma RC's

- Granite

I've been running, jumping, crashing my Granite for 2 years. Never thread locked those screws. They have never backed out on me.

RCbuzz

Very Active Member

- Messages

- 2,906

- Reaction score

- 5,113

- Arrma RC's

- Granite

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Senton 3s

Same story here, I have not had those back out on me (no Loctite). I suspect its due to the plastic housing actually acting similar to a lock washer and preventing reverse movement on those screws.

For the motor screws, I definitely Loctite those.

For the motor screws, I definitely Loctite those.

- Thread starter

- #20

Thanks everyone for the input. I had a brainwave to check the technical sheet that comes with the manual, and it showed threadlock so I erred on the side of caution and that’s what I ended up doing. But I agree that it probably isn't strictly necessary.

I had to dig the technical sheet out of a closet given HH doesn’t offer it as a support download which is weird. As it’s more useful than the actual manual.

The mesh was tighter than I would have set myself, but I didn’t see any sign of abnormal wear after 15+ packs so I left it alone. The spur gear is surprisingly true to round so maybe that helps (if it ain’t broke…)

Side note the power module design in general seems to suck. Needs prying to remove and it’s a bear to get back in unless you line up the power module and diff shaft just right or maybe there is a trick to it I am missing?

or maybe there is a trick to it I am missing?

I had to dig the technical sheet out of a closet given HH doesn’t offer it as a support download which is weird. As it’s more useful than the actual manual.

The mesh was tighter than I would have set myself, but I didn’t see any sign of abnormal wear after 15+ packs so I left it alone. The spur gear is surprisingly true to round so maybe that helps (if it ain’t broke…)

Side note the power module design in general seems to suck. Needs prying to remove and it’s a bear to get back in unless you line up the power module and diff shaft just right

Similar threads

- Replies

- 18

- Views

- 1K

- Replies

- 21

- Views

- 828