pomplemus

Active Member

NOTE: I lagged a bit on posting this thread and got too excited rushing forwards when building, so the truck is already complete, but I figured I would still post this log in installments.

Hey all, been here for a few years now with my original Kraton, but I figured I'd finally get a build log posted!

So, over the course of 3 years I’ve collected quite a few spare parts and retained originals when fully M2Cing out my rig. A few months ago I realized I had almost all the parts I needed to build an entire second truck. A dangerous situation I’m sure many of you have been in.

When getting other replacements from Jenny’s and the like, I also picked up the other remaining parts I needed, bit by bit. I wanted to make a “new” build utilizing as much of my original parts/spares as possible, but not just another high speed ultra-basher Kraton, since I already have one of those pretty much exactly how I want it.

I considered a road/speed build, but if I just slam my other rig and mount road crushers it pretty much fulfills that, plus many other people have already done that; I wanted to get a bit more creative. An ultralight basher (akin to @Xjeepguy 's Superleggera, awesome build) was also enticing, but would end up replacing almost all stock parts, defeating the purpose of the build.

What I have never seen before however, is a slow speed trail truck/crawler! I was initially struck by the idea when I took my Kraton with me when camping, and it actually did surprisingly well at a walking pace on some rough slopes/rocks, partially thanks to the sensored 1717. Optimizing for slow speed trail walking/crawling could be pretty cheap to execute as well, suspension tuning is mostly free and can go a long way.

Thus Kraton Kawler was conceived! It’s definitely not going to be a true “rock crawler”, since the chassis is just too far off a purpose built solid axle design, rather more focused as a slow/medium speed trail truck that can also do some light to moderate bashing. But, alliteration is fun, so I’m sticking with “Kraton Krawler” as the name.

I was further convinced of this build a little while ago when visiting my family in Slovakia, turns out one of my cousins is super into trail scalers/crawlers and there is an awesome community over there. I joined him on a couple of events and had a huge amount of fun with the trucks he let me borrow, definitely something different than high speed bashing! Its nice to get out on a walk in the woods with a truck sometimes.

Some general goals:

Anyway, the way I see it there are a few critical things to address to make this embody what I want it to:

A while back on ebay I found an awesome deal for mojave rear shocks ($12 for a set of two!) so I went ahead and bought three sets. I figure putting rears on the front will jack that up, and I can figure out some alternate mounts for the rear

The RC4WD Mickey Thompson 40 Series Baja MTZ tires check the boxes for big (8”!), soft/grippy, and cool looking. They are pricey, but I managed to find some new ones already pre-mounted to some old Proline beadlocks from a local FB seller for a reasonable price! The bead locks will go a long way towards looking cool, but I will need to figure something out for the 23 mm hexes.

Torque/slow speed comes from both gearing and Kv. The smallest mod 1 pinion I could find for a 5 mm shaft is 11t, and I did actually find an eBay special spur slightly bigger than stock at 52t. We’ll see how it holds up.

The lowest Kv reasonably cheap (under $100) sensored motor I could find was the HobbyStar 4274 1350 Kv. I don’t think this truck needs a massive amount of power, just good torque and low speed control, so this should be alright. Between the 11/52 gearing and 1350Kv motor, but bigger 8” tires, I think this should top out around 30-35 mph, which sounds about right for a low/medium speed trail truck.

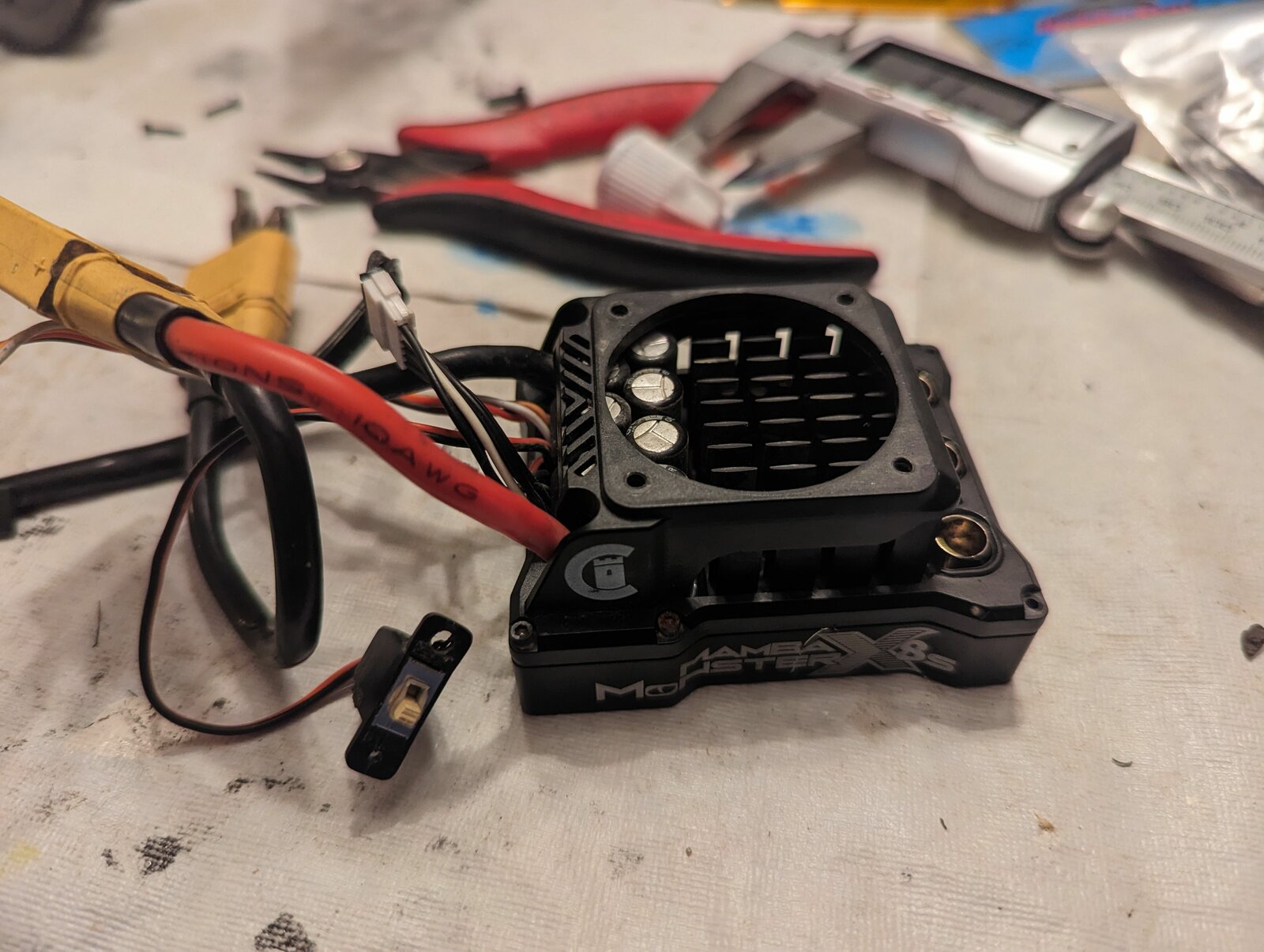

After a WTB sensored ESC post in the classifieds sections, @Sumnig66 came through with a solid price for a used Mamba Monster X 8S! Definitely overkill, but hey, it works great on my other Kraton, so it should do well here too.

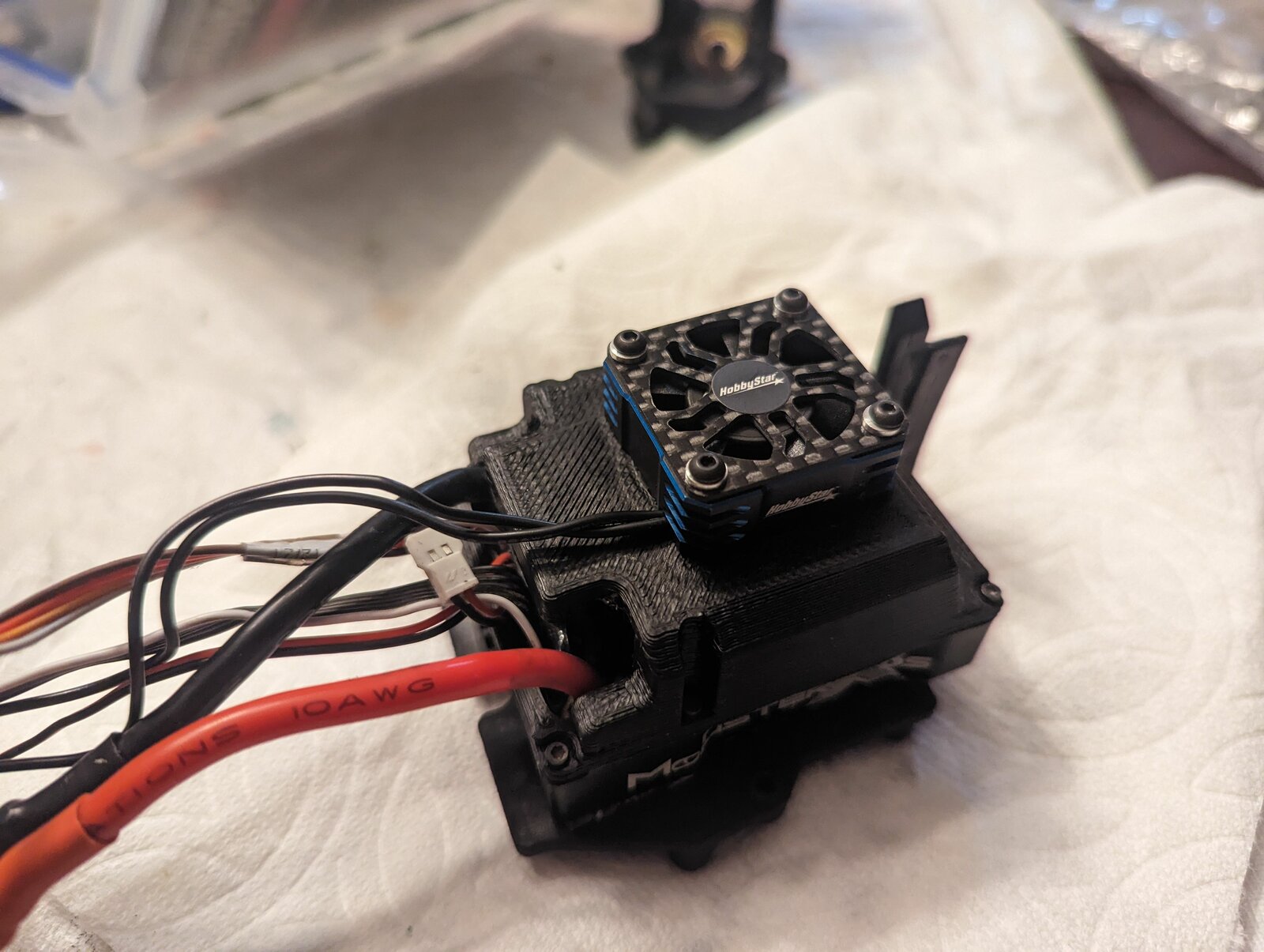

The first order of business was to clean up the ESC. getting rid of the XT90s and putting on an IC5. In my experience, they simply hold up better long term and are more reliable than XT90s. I also swapped out the top case/fan mount for a 3D printed one of my own design that is much tougher, the stock Castle one tends to crack on hard landings.

Thus it begins!

More to come soon.

I'll finish off this first post by paying the cat tax, my buddy Chewie hung out on the chair next to me for most of build, the dogs couldn't be bothered and stayed buried under the blankets on the couch.

Hey all, been here for a few years now with my original Kraton, but I figured I'd finally get a build log posted!

So, over the course of 3 years I’ve collected quite a few spare parts and retained originals when fully M2Cing out my rig. A few months ago I realized I had almost all the parts I needed to build an entire second truck. A dangerous situation I’m sure many of you have been in.

When getting other replacements from Jenny’s and the like, I also picked up the other remaining parts I needed, bit by bit. I wanted to make a “new” build utilizing as much of my original parts/spares as possible, but not just another high speed ultra-basher Kraton, since I already have one of those pretty much exactly how I want it.

I considered a road/speed build, but if I just slam my other rig and mount road crushers it pretty much fulfills that, plus many other people have already done that; I wanted to get a bit more creative. An ultralight basher (akin to @Xjeepguy 's Superleggera, awesome build) was also enticing, but would end up replacing almost all stock parts, defeating the purpose of the build.

What I have never seen before however, is a slow speed trail truck/crawler! I was initially struck by the idea when I took my Kraton with me when camping, and it actually did surprisingly well at a walking pace on some rough slopes/rocks, partially thanks to the sensored 1717. Optimizing for slow speed trail walking/crawling could be pretty cheap to execute as well, suspension tuning is mostly free and can go a long way.

Thus Kraton Kawler was conceived! It’s definitely not going to be a true “rock crawler”, since the chassis is just too far off a purpose built solid axle design, rather more focused as a slow/medium speed trail truck that can also do some light to moderate bashing. But, alliteration is fun, so I’m sticking with “Kraton Krawler” as the name.

I was further convinced of this build a little while ago when visiting my family in Slovakia, turns out one of my cousins is super into trail scalers/crawlers and there is an awesome community over there. I joined him on a couple of events and had a huge amount of fun with the trucks he let me borrow, definitely something different than high speed bashing! Its nice to get out on a walk in the woods with a truck sometimes.

Some general goals:

- It must remain 6S powered. I don’t want to invest in and more importantly lug around a whole other set of lower voltage batteries when I go bashing.

- I want to use as many of my leftover spares/original parts from my Kraton 6S V4 I bought 3 years ago. Practical application of Theseus’s ship…

- Stay on a reasonable budget. I want to stay in the spirit of bringing a bag of old/worn spares to life!

- It must have a sensored motor, sensorless is just going to be too juddery at low speed for what I want to do. This is a little at odds with the above goal since I can’t use my old BLX185, but oh well.

Anyway, the way I see it there are a few critical things to address to make this embody what I want it to:

- Suspension jacked waaaay up for maximum ground clearance/breakover angle

- Some big and soft cool looking tires for for clearance and grippiness

- Geared as low as possible for max torque/smoothness at low speeds

A while back on ebay I found an awesome deal for mojave rear shocks ($12 for a set of two!) so I went ahead and bought three sets. I figure putting rears on the front will jack that up, and I can figure out some alternate mounts for the rear

The RC4WD Mickey Thompson 40 Series Baja MTZ tires check the boxes for big (8”!), soft/grippy, and cool looking. They are pricey, but I managed to find some new ones already pre-mounted to some old Proline beadlocks from a local FB seller for a reasonable price! The bead locks will go a long way towards looking cool, but I will need to figure something out for the 23 mm hexes.

Torque/slow speed comes from both gearing and Kv. The smallest mod 1 pinion I could find for a 5 mm shaft is 11t, and I did actually find an eBay special spur slightly bigger than stock at 52t. We’ll see how it holds up.

The lowest Kv reasonably cheap (under $100) sensored motor I could find was the HobbyStar 4274 1350 Kv. I don’t think this truck needs a massive amount of power, just good torque and low speed control, so this should be alright. Between the 11/52 gearing and 1350Kv motor, but bigger 8” tires, I think this should top out around 30-35 mph, which sounds about right for a low/medium speed trail truck.

After a WTB sensored ESC post in the classifieds sections, @Sumnig66 came through with a solid price for a used Mamba Monster X 8S! Definitely overkill, but hey, it works great on my other Kraton, so it should do well here too.

The first order of business was to clean up the ESC. getting rid of the XT90s and putting on an IC5. In my experience, they simply hold up better long term and are more reliable than XT90s. I also swapped out the top case/fan mount for a 3D printed one of my own design that is much tougher, the stock Castle one tends to crack on hard landings.

Thus it begins!

More to come soon.

I'll finish off this first post by paying the cat tax, my buddy Chewie hung out on the chair next to me for most of build, the dogs couldn't be bothered and stayed buried under the blankets on the couch.