- Messages

- 1,755

- Reaction score

- 3,176

- Location

- Wenatchee, WA

- Arrma RC's

- 4x4-Mega

- BigRock 4x4

- Felony

- Granite

- Infraction

- Limitless

- Kraton 6s

- Outcast 4s

- Typhon 3s

- Voltage

Finally got my day 1 pre-order from Horizon after it was 2.5 weeks late from the date they said it was shipping. The size of this thing in pics is deceiving, seems way bigger IRL.

First things first is to drain the diffs and verify the rear diff shim situation and remedy if needed, then add new diff oil (50k/200k/25k)

For electronics it will be getting the following:

For motors I got two options so I will leave up a poll to help me decide...

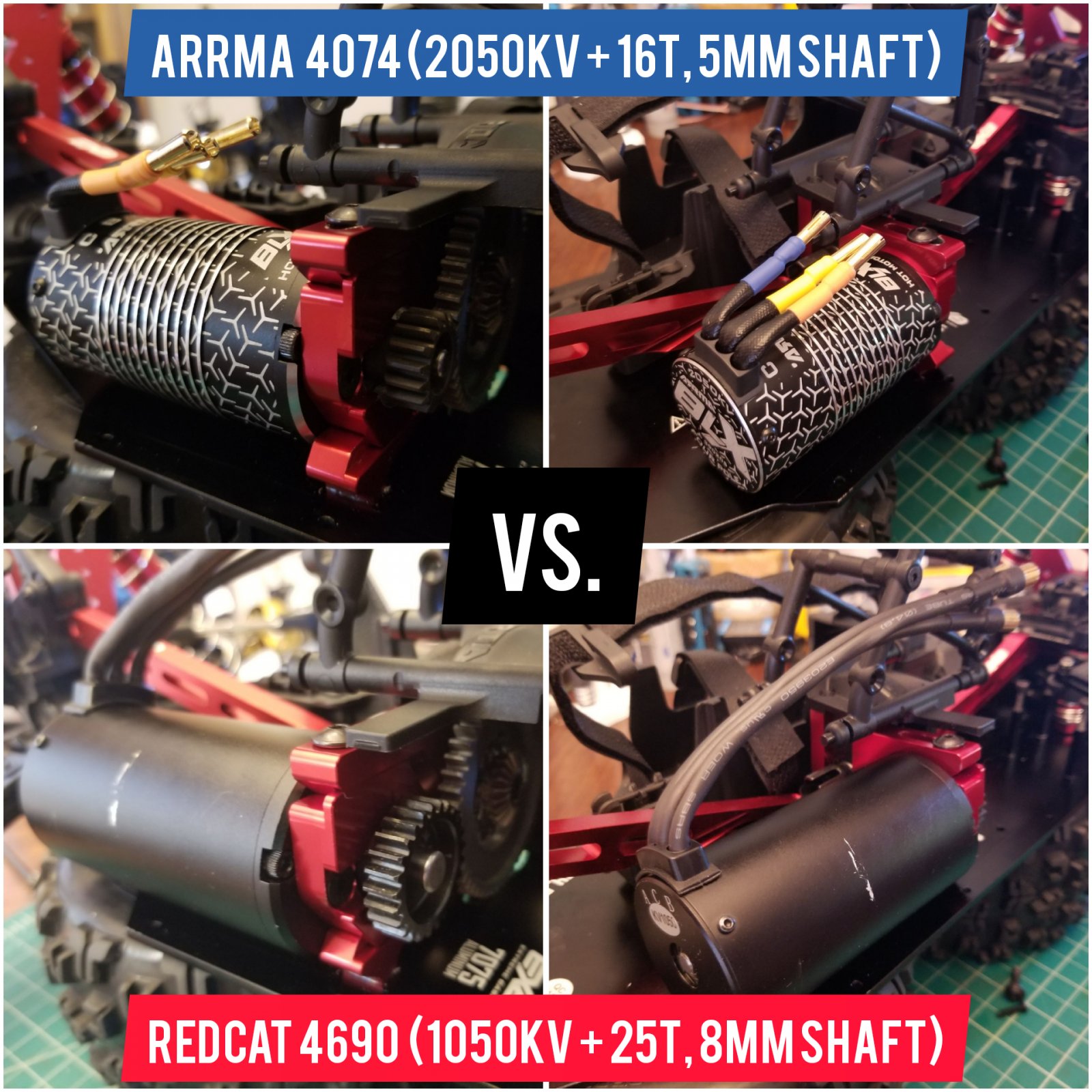

The 4074 arrma motor is a motor I know so I think pairing it with a 16mm pinion with the dual fan+heatsink combo should be decent. However, I picked up this Redcat 1/5 scale 4690 motor on clearance and want to give it a try. It's got a pretty low kv (1050kv) which is half the rpm as the Arrma 4074, but I think it will be a torque monster. Pairing it with a huge 25T pinion it should still make decent speed (60mph ish).

I've test fitted both and with some modifications to the motor mount (center bored out to 17mm to allow fitment over the huge pinion, and motor slider trimmed slightly) the 4690 fits like a glove and it has almost no gap between it and the chassis, this meaning it's heavy weight won't be putting vertical strain on the motor mount.

Anyways more pics to come as I progress.

First things first is to drain the diffs and verify the rear diff shim situation and remedy if needed, then add new diff oil (50k/200k/25k)

For electronics it will be getting the following:

- Hex6 (160A, 6s version) ESC with a 40mm Wild Turbo Fans (WTF) high CFM fan retrofit

- DS3235SG 35kg servo

- DumboRC X6 radio with 6 channel gyro receiver

- 2 x 30mm PowerHobby high CFM motor fans and heatsink

For motors I got two options so I will leave up a poll to help me decide...

- Option#1: Arrma 4074 (2050kv) + 16T pinion (calculated top speed: 76mph @ 6s)

- Option#2: Redcat 4690 (1050kv, 8mm shaft!) + 25T pinion (calculated top speed: 61mph @ 6s)

The 4074 arrma motor is a motor I know so I think pairing it with a 16mm pinion with the dual fan+heatsink combo should be decent. However, I picked up this Redcat 1/5 scale 4690 motor on clearance and want to give it a try. It's got a pretty low kv (1050kv) which is half the rpm as the Arrma 4074, but I think it will be a torque monster. Pairing it with a huge 25T pinion it should still make decent speed (60mph ish).

I've test fitted both and with some modifications to the motor mount (center bored out to 17mm to allow fitment over the huge pinion, and motor slider trimmed slightly) the 4690 fits like a glove and it has almost no gap between it and the chassis, this meaning it's heavy weight won't be putting vertical strain on the motor mount.

Anyways more pics to come as I progress.

Attachments

Last edited: