- Thread starter

- #21

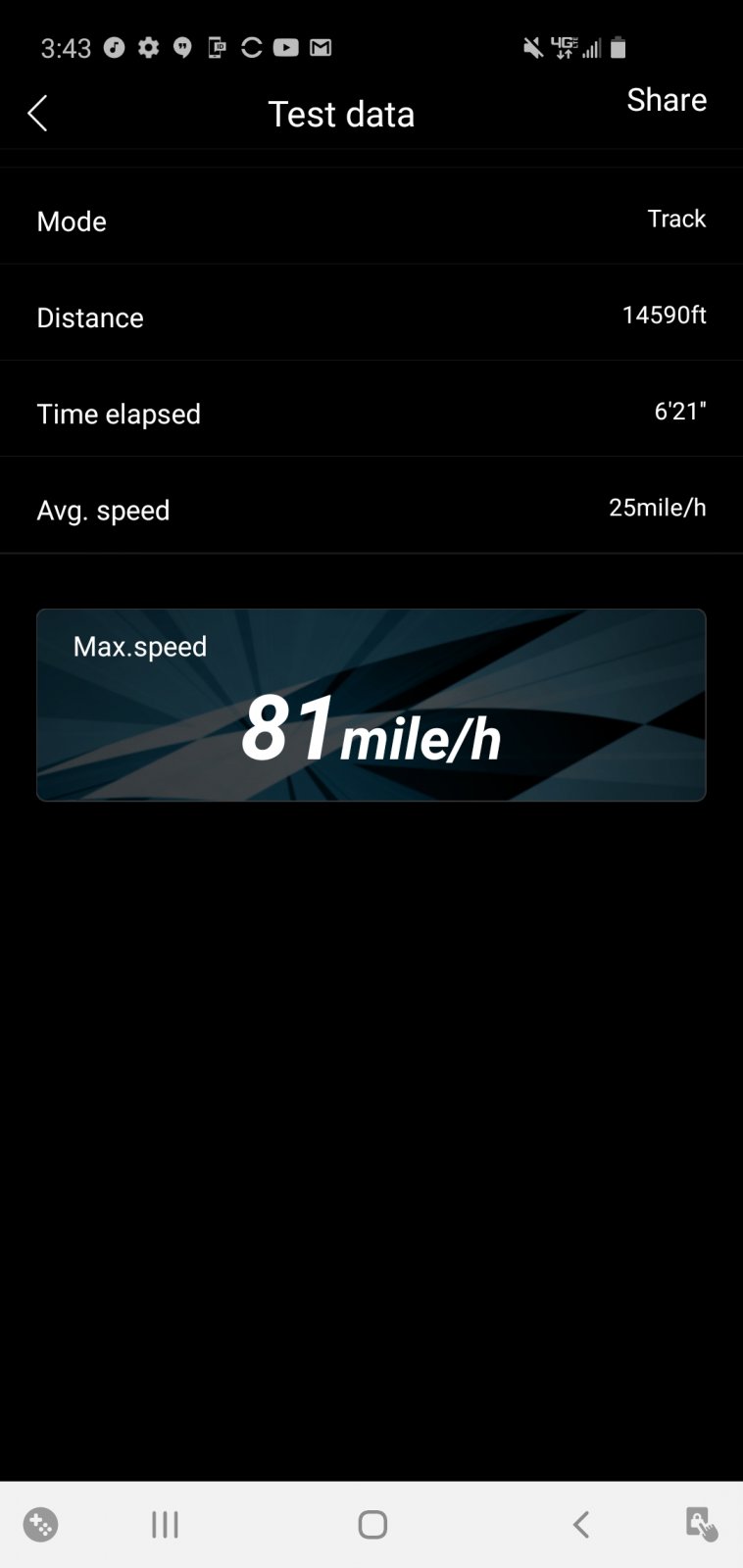

I achieved 81mph in a parking lot racing around islands. A bit on the fast side. Hit thermal on the motor (180*) at about 7 minutes in. 23/46 gearing. I'm not sure why but this car feels a bit intimidating. Ive gone significantly faster in my typhon...it just feels different i suppose.