smirkracing

Active Member

- Messages

- 105

- Reaction score

- 117

- Location

- SF Bay Area

- Arrma RC's

- BigRock

- Fireteam

- Gorgon

- Granite

- Kraton 6s

- Typhon 6s

@parcou thanks for your advice. I received the tekno driveshafts. However, there seems to be a slight issue... first off, the instructions say " a very small amount of material may need to be removed where the outdrives exit...", but they don't really specify what they mean. Here's a pic of the instruction sheet:

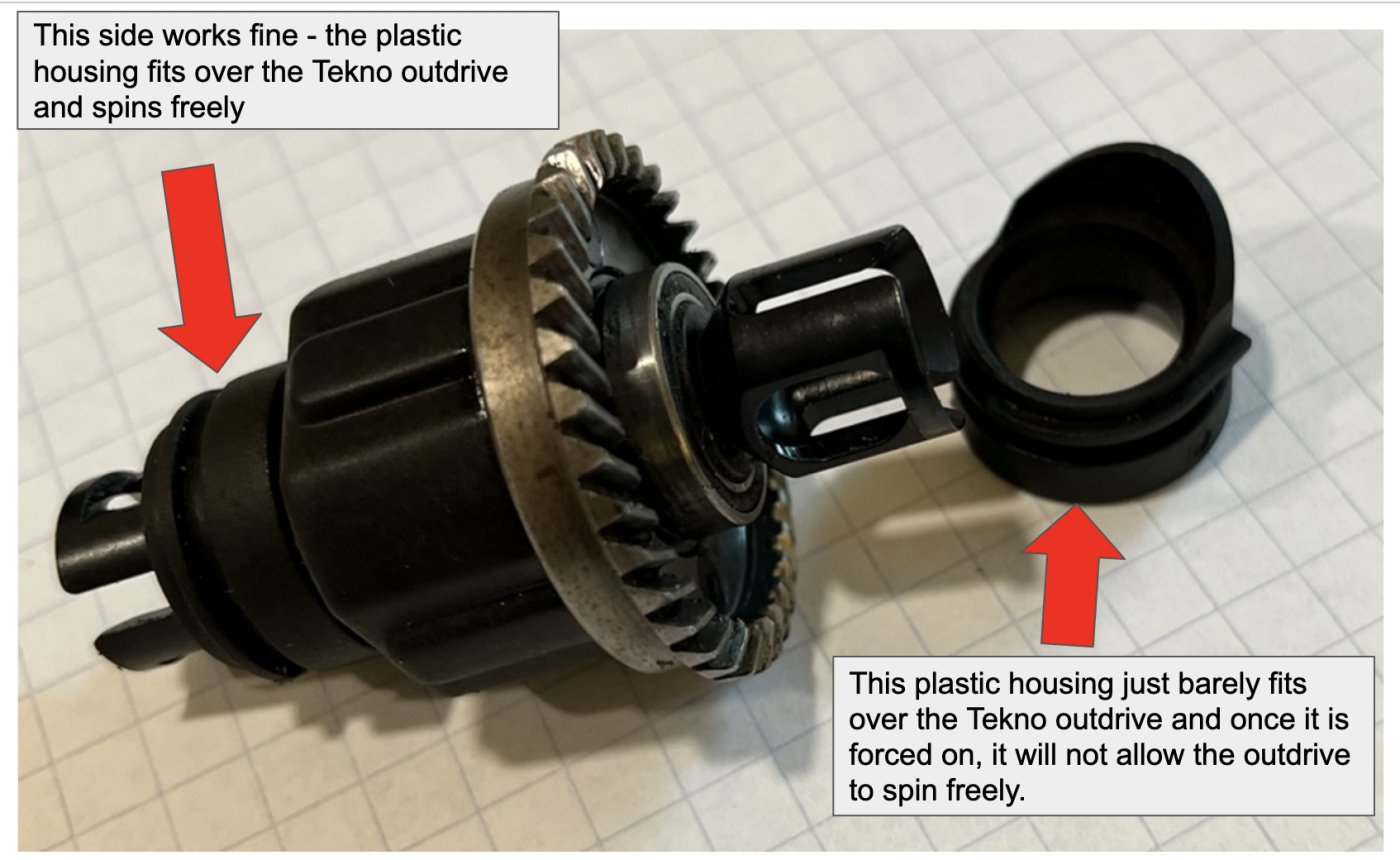

Second, when I reassembled the gearbox, one of those plastic 'housings' that goes on the outside of the outdrives is totally bound up. Here's a pic (since I am sure that description did nothing for anyone):

The only solution I see is hitting the entire inside of the problematic housing with a dremel and removing maybe 1mm (or less) of material all the way around the inside of the housing such that it doesn't bind up the outdrive. Before I do that, I wanted to check with the experts on this thread... I can't be the only one experiencing this issue. Is this what the instructions mean when they refer to a small amount of material needing to be removed?

Thank you!

Second, when I reassembled the gearbox, one of those plastic 'housings' that goes on the outside of the outdrives is totally bound up. Here's a pic (since I am sure that description did nothing for anyone):

The only solution I see is hitting the entire inside of the problematic housing with a dremel and removing maybe 1mm (or less) of material all the way around the inside of the housing such that it doesn't bind up the outdrive. Before I do that, I wanted to check with the experts on this thread... I can't be the only one experiencing this issue. Is this what the instructions mean when they refer to a small amount of material needing to be removed?

Thank you!