So you have a Senton with 14mm hexes and you want to upgrade to 17mm? Here are your options and my review on each one as well as a quick guide to what I found as the very best option at the end:

What you need to know:

Stock Arrma Senton BLX 3s has 14mm hexes on 6mm axles using 2.5mm pins.

A list of options that are not what I went with and why (All amazon links for consistency):

Option 1) Pro D.M.T. Kit with 4 Adapters for 1:10 RC Car 6mm Axle to 1:8 Wheels with 17mm Hex Hub (https://www.amazon.com/gp/product/B073RV4HZ2/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

These work by just removing your 14mm hex and placing these directly over the axle. They come with pins that are too small and if you try to reuse your stock pins, they are too short and have a little too much play. There is also a gap between the bearing and the adapter which, all combined, leads to a lot of play. You can get these to work by buying 6mm ID / 10mm OD .5mm thickness shims and putting 1 shim in the back wheels and 1-2 shims in the front, then finding or cutting 2.5mm pins to fit and press it all together snug. It'll be ok at first, but after driving on these a while, they still loosen up and have more play than they should. A good adapter would have had a long nut in the middle as well as a groove, not a hole, for the hex so you can wrench the nut tight and get that hex tight against the bearing. It's unfortunate that they didn't do that because that would have made for a great upgrade path. A DIYer could dremel the notch for the pin and drill out the hole and find the long nut on shaft to use, but there are easier options.

Option 2) HobbyPark Aluminum Wheel hubs 17mm Hex Nuts w/Screw Pins Threadlock Replace 5353X for RC Traxxas 1/10 E-Revo E-Maxx (Brushless) Revo 3.3 Slayer Pro 4x4 Summit XO-1 (Set of 4) (Gray) (https://www.amazon.com/gp/product/B07J54YRS1/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

Same problems as the Pro DMT kit but they were even looser for me. I have to imagine that the Traxxas 5353X suffers from the same problem but I haven't tried those. There is no amount of shimming that will make these fully tight, they just don't fit well. They could be DIY improved as mentioned for option 1, though, but there are easier options.

Best option:

6mm shim, 12mm hex with stock or 2.5mm pin, 17mm adapter - This adds some offset, but some may like that. See option below for no offset solution

Duratrax 12mm Aluminum Wheel Hub Adapter ARRMA 4x4 (4), DTXC3596 (https://www.amazon.com/DuraTrax-Aluminum-Wheel-Adapter-ARRMA/dp/B07G5KSH4B ) +

4-Pack 12mm to 17mm Wheel Hex Hub Adapter Extension Conversion for 1/10 RC Car and Upgrade 1/8 Tires

(https://www.amazon.com/gp/product/B07KKKFYKK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

Alternative 12mm to 17mm adapter for NO OFFSET 17mm:

Mxfans Titanium Alloy N10237 RC 1:10 Model Car Wheel Hex Adapter 12mm to 17mm Upgrade Parts Set of 4 (https://www.amazon.com/gp/product/B073ZBDRTH/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

I tested both of these 12mm to 17mm solutions and found that even though they need a shim, because of the center axle nut, they give you much less play and more durability than the direct 17mm adapters. First of all, you will need a .5mm shim (standard washers are 1.5mm so don't use those):

Shims (you want these for ALL solutions) -

M6x10mmx0.5mm Stainless Steel Round Flat Washer for Bolt Screw 100Pcs: https://www.amazon.com/gp/product/B015A3A222/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

2.5mm pins (optional, tighter fit than stock, may not work with some 12mm hexes but they do fit through the axle) https://www.amazon.com/gp/product/B07MQZXWMV/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8&psc=1

Step 1:

Buy your shims, 12mm hexes and 17mm adapters.

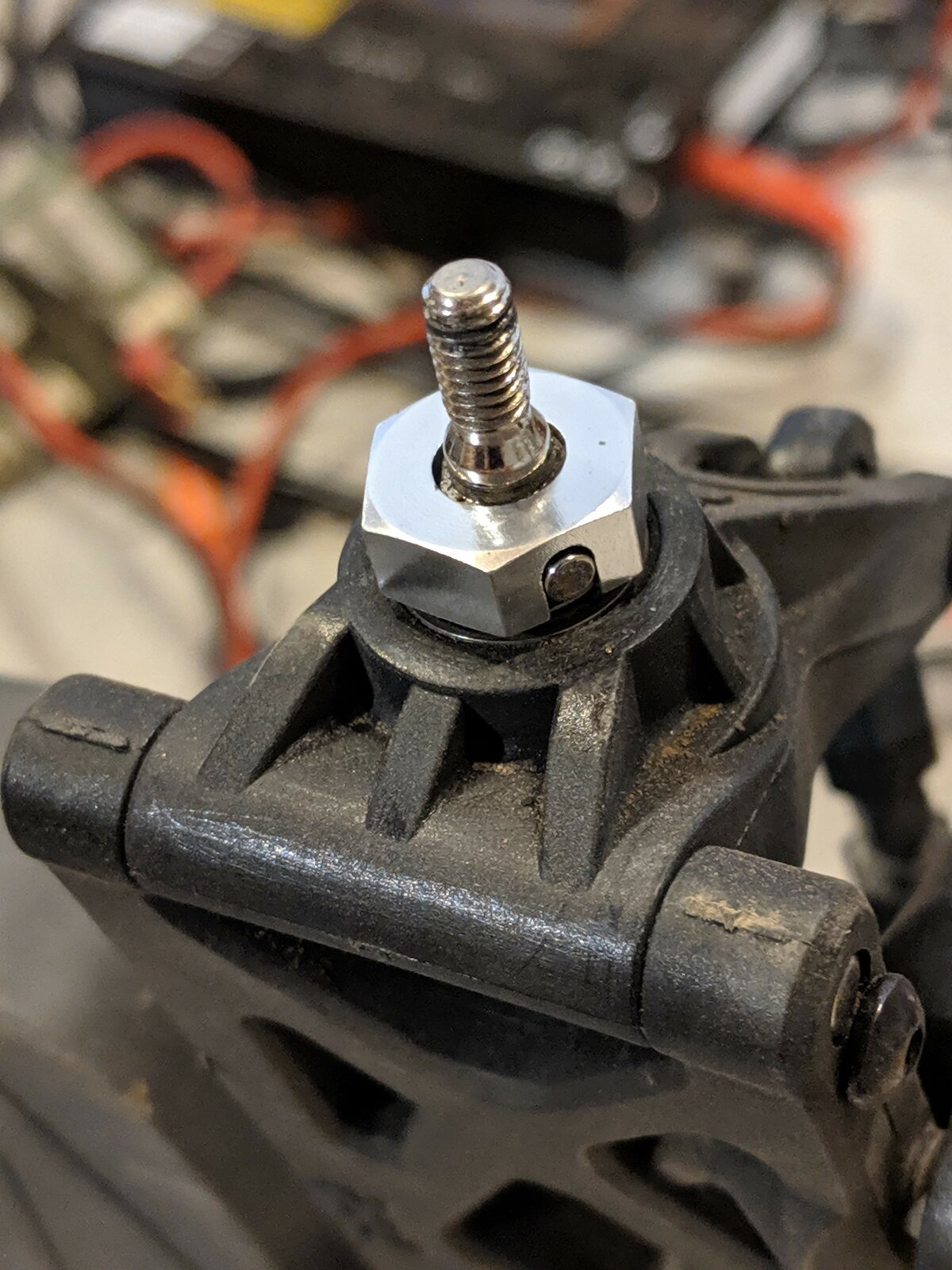

Step 2-?: Follow the photo guide - use a drop of loctite blue on the nut connections

I had to cut the body to make room for the offset on the back wheel but I don't consider that a big deal. I really enjoy the performance of 17mm buggy wheels on this truck and hope this was a helpful post!

What you need to know:

Stock Arrma Senton BLX 3s has 14mm hexes on 6mm axles using 2.5mm pins.

A list of options that are not what I went with and why (All amazon links for consistency):

Option 1) Pro D.M.T. Kit with 4 Adapters for 1:10 RC Car 6mm Axle to 1:8 Wheels with 17mm Hex Hub (https://www.amazon.com/gp/product/B073RV4HZ2/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

These work by just removing your 14mm hex and placing these directly over the axle. They come with pins that are too small and if you try to reuse your stock pins, they are too short and have a little too much play. There is also a gap between the bearing and the adapter which, all combined, leads to a lot of play. You can get these to work by buying 6mm ID / 10mm OD .5mm thickness shims and putting 1 shim in the back wheels and 1-2 shims in the front, then finding or cutting 2.5mm pins to fit and press it all together snug. It'll be ok at first, but after driving on these a while, they still loosen up and have more play than they should. A good adapter would have had a long nut in the middle as well as a groove, not a hole, for the hex so you can wrench the nut tight and get that hex tight against the bearing. It's unfortunate that they didn't do that because that would have made for a great upgrade path. A DIYer could dremel the notch for the pin and drill out the hole and find the long nut on shaft to use, but there are easier options.

Option 2) HobbyPark Aluminum Wheel hubs 17mm Hex Nuts w/Screw Pins Threadlock Replace 5353X for RC Traxxas 1/10 E-Revo E-Maxx (Brushless) Revo 3.3 Slayer Pro 4x4 Summit XO-1 (Set of 4) (Gray) (https://www.amazon.com/gp/product/B07J54YRS1/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

Same problems as the Pro DMT kit but they were even looser for me. I have to imagine that the Traxxas 5353X suffers from the same problem but I haven't tried those. There is no amount of shimming that will make these fully tight, they just don't fit well. They could be DIY improved as mentioned for option 1, though, but there are easier options.

Best option:

6mm shim, 12mm hex with stock or 2.5mm pin, 17mm adapter - This adds some offset, but some may like that. See option below for no offset solution

Duratrax 12mm Aluminum Wheel Hub Adapter ARRMA 4x4 (4), DTXC3596 (https://www.amazon.com/DuraTrax-Aluminum-Wheel-Adapter-ARRMA/dp/B07G5KSH4B ) +

4-Pack 12mm to 17mm Wheel Hex Hub Adapter Extension Conversion for 1/10 RC Car and Upgrade 1/8 Tires

(https://www.amazon.com/gp/product/B07KKKFYKK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

Alternative 12mm to 17mm adapter for NO OFFSET 17mm:

Mxfans Titanium Alloy N10237 RC 1:10 Model Car Wheel Hex Adapter 12mm to 17mm Upgrade Parts Set of 4 (https://www.amazon.com/gp/product/B073ZBDRTH/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 )

I tested both of these 12mm to 17mm solutions and found that even though they need a shim, because of the center axle nut, they give you much less play and more durability than the direct 17mm adapters. First of all, you will need a .5mm shim (standard washers are 1.5mm so don't use those):

Shims (you want these for ALL solutions) -

M6x10mmx0.5mm Stainless Steel Round Flat Washer for Bolt Screw 100Pcs: https://www.amazon.com/gp/product/B015A3A222/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

2.5mm pins (optional, tighter fit than stock, may not work with some 12mm hexes but they do fit through the axle) https://www.amazon.com/gp/product/B07MQZXWMV/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8&psc=1

Step 1:

Buy your shims, 12mm hexes and 17mm adapters.

Step 2-?: Follow the photo guide - use a drop of loctite blue on the nut connections

I had to cut the body to make room for the offset on the back wheel but I don't consider that a big deal. I really enjoy the performance of 17mm buggy wheels on this truck and hope this was a helpful post!

Last edited: