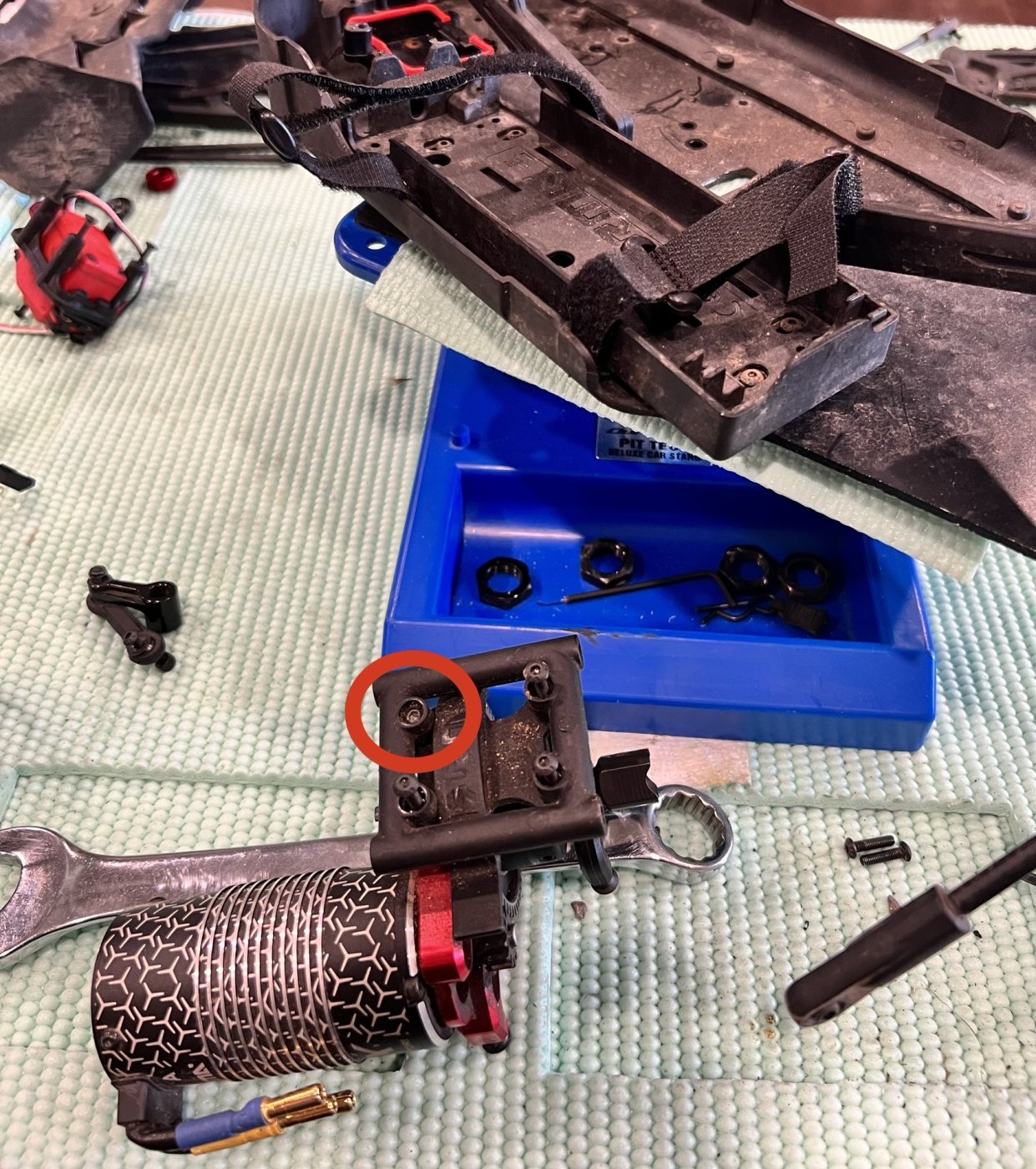

So I stripped a screw on my Kraton 6S trying to get the center diff out.

My plan is to dremel a slot, but since it’s recessed in plastic, I’ll have to cut some of that as well. So my question is which orientation should I make the cut to retain as much structural integrity as possible?

My plan is to dremel a slot, but since it’s recessed in plastic, I’ll have to cut some of that as well. So my question is which orientation should I make the cut to retain as much structural integrity as possible?