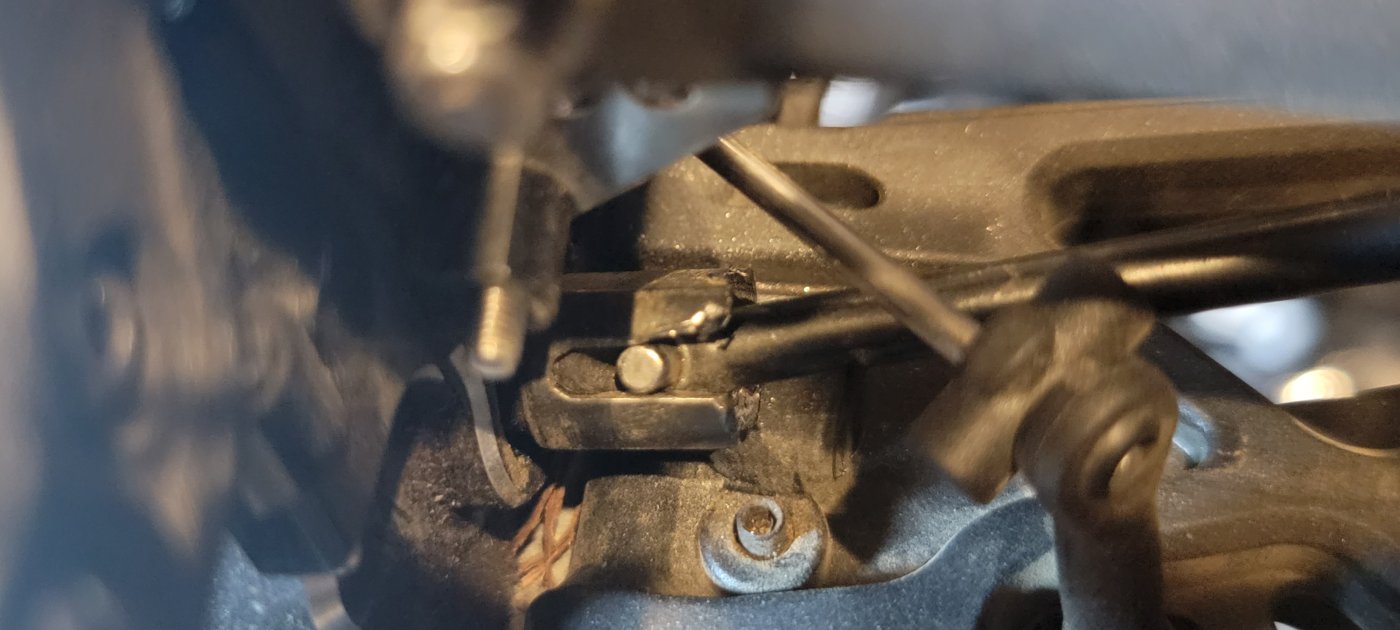

So if you've seen my build log you know I have done almost every mod available on my K6 EXB XL build. Well, I was doing some testing and tuning today to get it dialed in before a ride to the track for a nice bash. I hit a small speed bump in my parking lot, did a little end over end and landed on the wheels... nothing really hard, nothing major. Well, on the trip back down the road to me it did the dreded pulling that it does when the rear diff goes out!  I brought it inside to take a look. The left rear drive shaft was missing! So, I walked outside and found it on the ground where the little cartwheel took place. I went back inside and lined it up and noticed the diff outdrive cup is a MESS! Common Arrma! Stop using garbage metal! I have replace everything but that and the shafts! I am not pulling the diffs again to put stocks in. More money on M2C parts now! Jesus, I thought I could at least get one good run in before something broke!

I brought it inside to take a look. The left rear drive shaft was missing! So, I walked outside and found it on the ground where the little cartwheel took place. I went back inside and lined it up and noticed the diff outdrive cup is a MESS! Common Arrma! Stop using garbage metal! I have replace everything but that and the shafts! I am not pulling the diffs again to put stocks in. More money on M2C parts now! Jesus, I thought I could at least get one good run in before something broke!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton Arrma out drive cups now! 🤬

- Thread starter Jeremy15086

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 2,923

- Reaction score

- 6,295

- Location

- Potsdam, New York, (You-S-Eh)

- Arrma RC's

- Infraction

- Kraton 8S

- Kraton 6s

- Mojave

- Mojave EXB

- Outcast 4s

- Senton 3s

- Talion

- Typhon 3s

Wow.So if you've seen my build log you know I have done almost every mod available on my K6 EXB XL build. Well, I was doing some testing and tuning today to get it dialed in before a ride to the track for a nice bash. I hit a small speed bump in my parking lot, did a little end over end and landed on the wheels... nothing really hard, nothing major. Well, on the trip back down the road to me it did the dreded pulling the it does when the rear diff goes out!I brought it inside to take a look. The left rear drive shaft was missing! So, I walked outside and found it on the ground where the little cartwheel took place. I went back inside and lined it up and noticed the diff outdrive is a MESS! Common Arrma! Stop using garbage metal! I have replace everything but that and the shafts! I am not pulling the diffs again to put stocks in. More money on M2C parts now! Jesus, I thought I could at least get one good run in before something broke!

View attachment 232589

If you want to run immediately, you could flip the cups and maybe get a couple runs out of them.

- Thread starter

- #3

I don't want to take the diffs apart again just for that. My goal with this build was replace everything that breaks. I almost pulled the trigger on those cups and shafts so many times but didn't. I knew that was a mistake. Lesson learned.

Now I'm like "F it! I'm getting all the cups and shafts and getting this sob DONE 100%"!

Now I'm like "F it! I'm getting all the cups and shafts and getting this sob DONE 100%"!

parcou

Premium Member!

Premium Member

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,236

- Reaction score

- 9,150

- Location

- Memphis, TN

- Arrma RC's

- BigRock

- Felony

- Fireteam

- Granite

- Infraction

- Kraton EXB

- Talion EXB

- Typhon TLR

- Vorteks

Feel ya Man...in the end, I have M2C outdrives and their driveshafts....by force. Well, I replaced the driveshafts before ever driving it....but I was later forced to get better outdrives.So if you've seen my build log you know I have done almost every mod available on my K6 EXB XL build. Well, I was doing some testing and tuning today to get it dialed in before a ride to the track for a nice bash. I hit a small speed bump in my parking lot, did a little end over end and landed on the wheels... nothing really hard, nothing major. Well, on the trip back down the road to me it did the dreded pulling that it does when the rear diff goes out!I brought it inside to take a look. The left rear drive shaft was missing! So, I walked outside and found it on the ground where the little cartwheel took place. I went back inside and lined it up and noticed the diff outdrive cup is a MESS! Common Arrma! Stop using garbage metal! I have replace everything but that and the shafts! I am not pulling the diffs again to put stocks in. More money on M2C parts now! Jesus, I thought I could at least get one good run in before something broke!

View attachment 232589

https://m2cracing.net/arrma/563-m2c3185-arrma-differential-out-drives.html

- Messages

- 4,384

- Reaction score

- 7,407

- Arrma RC's

- Limitless

- Nero

- Talion

Mine are in worse condition than those...So if you've seen my build log you know I have done almost every mod available on my K6 EXB XL build. Well, I was doing some testing and tuning today to get it dialed in before a ride to the track for a nice bash. I hit a small speed bump in my parking lot, did a little end over end and landed on the wheels... nothing really hard, nothing major. Well, on the trip back down the road to me it did the dreded pulling that it does when the rear diff goes out!I brought it inside to take a look. The left rear drive shaft was missing! So, I walked outside and found it on the ground where the little cartwheel took place. I went back inside and lined it up and noticed the diff outdrive cup is a MESS! Common Arrma! Stop using garbage metal! I have replace everything but that and the shafts! I am not pulling the diffs again to put stocks in. More money on M2C parts now! Jesus, I thought I could at least get one good run in before something broke!

View attachment 232589

- Thread starter

- #6

I popped my drive shaft back in, tightened up my rear upper tie rods, lowered my droop screws a little more and gave it another go. Lasted about 10 minutes just driving it on the street before popping out again. Not even 1 jump.Mine are in worse condition than those...

I honestly have maybe 4-5 packs on this rig since it was brand new!

Oh I am on it! This is my M2C cart already to go.Feel ya Man...in the end, I have M2C outdrives and their driveshafts....by force. Well, I replaced the driveshafts before ever driving it....but I was later forced to get better outdrives.

https://m2cracing.net/arrma/563-m2c3185-arrma-differential-out-drives.html

What's another $230 at this point?

The only plus side is I held off doing my front and rear Arrma aluminum diff cases until something broke. I did the center one already. I'll probably hold off on rebuilding it until those output shafts break.

Last edited:

I’m building a new exb myself and I decided to go ahead and bite the bullet and install everything m2c had to offer driveline wise with the exception of the outer drive shafts. All the inner shafts, input cups and diff cups are a pain in the ass to install which I realized when I started putting stuff back together so I went ahead and upgraded it all. The only shafts that I haven’t replaced yet are the outer ones that go from the diffs to the wheels and I may still do those before I run it. I’ve got 90% of a stock exb in my spare parts for the truck now. With some stock diffs and a few other parts I could put together another stock kraton exb.I popped my drive shaft back in, tightened up my rear upper tie rods, lowered my droop screws a little more and gave it another go. Lasted about 10 minutes just driving it on the street before popping out again. Not even 1 jump.

I honestly have maybe 4-5 packs on this rig since it was brand new!

Oh I am on it! This is my M2C cart already to go.View attachment 232645 I was hoping I didn't need to do this for a while but... fudge it!

What's another $230 at this point?

The only plus side is I held off doing my front and rear Arrma aluminum diff cases until something broke. I did the center one already. I'll probably hold off on rebuilding it until those output shafts break.

- Thread starter

- #8

Yup! I do to. I just don't have arms and rear hubs, diff cups, shock tower mounts, internal diff gears, tie rods and ends, most of the drive shafts and maybe a couple of other things. I was considering getting the new RPM EXB arms for it but I wanted to wait until people used them to see how they are. I have heard bad things so, at some point I'll just get some stocks when I am ready to build the stock K6 EXB. Maybe I'll keep it as a back up rig or maybe trade it for something else.I’m building a new exb myself and I decided to go ahead and bite the bullet and install everything m2c had to offer driveline wise with the exception of the outer drive shafts. All the inner shafts, input cups and diff cups are a pain in the ass to install which I realized when I started putting stuff back together so I went ahead and upgraded it all. The only shafts that I haven’t replaced yet are the outer ones that go from the diffs to the wheels and I may still do those before I run it. I’ve got 90% of a stock exb in my spare parts for the truck now. With some stock diffs and a few other parts I could put together another stock kraton exb.

I was thinking the same thing. I’m about to take a 6s system out of my old Savage flux that would work fine if I was going to build it for trade. I think all im going to need is all 3 diffs by themselves and some shocksYup! I do to. I just don't have arms and rear hubs, diff cups, shock tower mounts, internal diff gears, tie rods and ends, most of the drive shafts and maybe a couple of other things. I was considering getting the new RPM EXB arms for it but I wanted to wait until people used them to see how they are. I have heard bad things so, at some point I'll just get some stocks when I am ready to build the stock K6 EXB. Maybe I'll keep it as a back up rig or maybe trade it for something else.

craig72

Active Member

- Messages

- 177

- Reaction score

- 198

- Arrma RC's

- Kraton EXB

- Nero

- Talion

- Typhon 6s

I was having the same problem with both my Talion and KEXB. It wasn't my droop screws, it was the compression side. So when I hit the brakes or anything that would push the shocks in like launching off the ramp. My go-to fix was to add short length of fuel line (from my old nitro days) to the shock rod. It limits the compression enough so that the damn dog bones stay where they're supposed toI popped my drive shaft back in, tightened up my rear upper tie rods, lowered my droop screws a little more and gave it another go. Lasted about 10 minutes just driving it on the street before popping out again. Not even 1 jump.

I honestly have maybe 4-5 packs on this rig since it was brand new!

- Thread starter

- #11

I noticed it was the top end. Thanks for this. Maybe I'll try this for now. Still going ham on the M2C parts... but in the mean time maybe I can still bash.

Can you tell me what gage the tubing you use is?

Can you tell me what gage the tubing you use is?

Snoprosledneck88

Active Member

I have seen people remove the spacers between the pillow ball screw and a-arm. When the pillow ball screws into the arm. That allows the driveshaft to set into the outdrive a little more. I had to do it on my outcast and it fixed that issue for meI noticed it was the top end. Thanks for this. Maybe I'll try this for now. Still going ham on the M2C parts... but in the mean time maybe I can still bash.

Can you tell me what gage the tubing you use is?

craig72

Active Member

- Messages

- 177

- Reaction score

- 198

- Arrma RC's

- Kraton EXB

- Nero

- Talion

- Typhon 6s

If you look on Amain hobbies, search for nitro fuel tubing. Its all pretty much the same size, maybe 2mm inner diameter. Fits all of my 6s cars just fine. Makes a nice bushing.I noticed it was the top end. Thanks for this. Maybe I'll try this for now. Still going ham on the M2C parts... but in the mean time maybe I can still bash.

Can you tell me what gage the tubing you use is?

Snoprosledneck88

Active Member

Seen another post about getting a small o-ring or two from the local hardware store and putting them on the shock shaft. Would save some shipping cost.If you look on Amain hobbies, search for nitro fuel tubing. It’s all pretty much the same size, maybe 2mm inner diameter. Fits all of my 6s cars just fine. Makes a nice bushing.

Jluther@becoinc

Active Member

- Messages

- 932

- Reaction score

- 986

- Arrma RC's

- Senton 6s

- Talion

I was having issues with outdrive cups so on the back I put those rubber spacer things in the wheel side to push the dog bone towards the diff. On the front I used a rasp bit to drill a couple mm back into the a-arm. I hardly ever break outdrives. It’s kind of a pain to wallow out the red aluminum cap out big enough for the ball end flange to go through but it’s worth it to me to never loose a front dog bone every time I send it.I removed the spacers on the arms but didn't help, still popping out. The tube on the shock shaft worked for me though.

Smilinbri

RC is a hobby. Arrma is a lifestyle.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 7,839

- Reaction score

- 23,275

- Location

- MD

- Arrma RC's

- Felony

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

- Vorteks

- Infraction 4x4

Great idea! But I swear I saw that same drill bit in the Adam & Eve catalog!!!I was having issues with outdrive cups so on the back I put those rubber spacer things in the wheel side to push the dog bone towards the diff. On the front I used a rasp bit to drill a couple mm back into the a-arm. I hardly ever break outdrives. It’s kind of a pain to wallow out the red aluminum cap out big enough for the ball end flange to go through but it’s worth it to me to never loose a front dog bone every time I send it.

View attachment 233116

View attachment 233117

View attachment 233118

Jluther@becoinc

Active Member

- Messages

- 932

- Reaction score

- 986

- Arrma RC's

- Senton 6s

- Talion

You’d have to be one horny SOB to bust a nut using that thing!Great idea! But I swear I saw that same drill bit in the Adam & Eve catalog!!!

Smilinbri

RC is a hobby. Arrma is a lifestyle.

Lifetime Premium!

Premium Member

ArrmaForum Fan

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 7,839

- Reaction score

- 23,275

- Location

- MD

- Arrma RC's

- Felony

- Notorious

- Senton 6s

- Senton 3s

- Typhon 6s

- Vorteks

- Infraction 4x4

O no, it's for the wifey!!You’d have to be one horny SOB to bust a nut using that thing!

EDIT: HA! I just got that!!

Jluther@becoinc

Active Member

- Messages

- 932

- Reaction score

- 986

- Arrma RC's

- Senton 6s

- Talion

Kidding around my friend. It does look a little perverted. I use it only for wallowing out holes In A-armsO no, it's for the wifey!!

EDIT: HA! I just got that!!