Just a hobby

Active Member

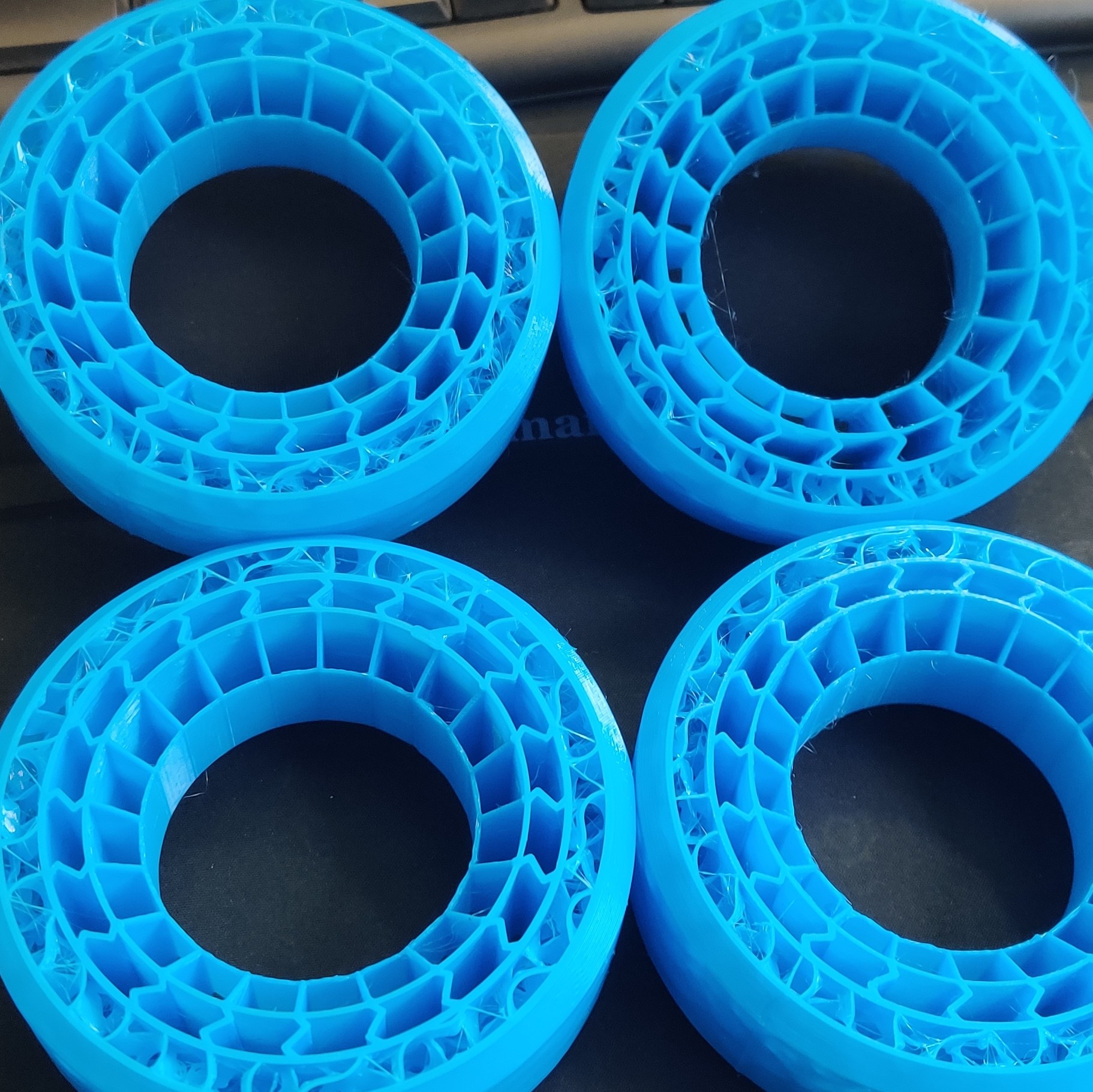

With the change in size I would try cutting the foam for the bigger part the try and trim the smaller part down to size, maybe new razorblade. You should be able to find sheets of foam the right thickness? Using glue on foams won't hold up long. On my hpi baja 5b ss the front tire foams came one long 2"×2" length was long enough to fit in the tire and had to be glued. Tires were very stiff compared to Xmaxx tires. Not sure how long the layering and gluing will preform or hold up in a soft tire. One peice shape the best you can.I think I understand what you're saying but, I haven't found any foam available that large. Are you talking about carving a foam from a block? The foams are indeed larger than the tire itself, or should be I'd say. Tricky part with the Xmaxx is the inner and outer diameter of the wheel are different. I've been looking at some 1/2" thick closed cell neoprene rubber foam on amazon. Was thinking I could layer it to acheive the thickness needed. Not sure how the layers will interact with each other though. Might be abrasive to itself, especially if some dirt gets in like I know it will..

I'm thinking the majority of the width needed for foam is 1 inch, then the outer bead is near 2 inches. I can see after taking the stock foams out that the "step" is likely were the stock foams failed. Like it seperated there and continued to disintegrate from that seam inward..

If all you can get are blocks of foam big enough. A electric carving knife should help alot.With the change in size I would try cutting the foam for the bigger part the try and trim the smaller part down to size, maybe new razorblade. You should be able to find sheets of foam the right thickness? Using glue on foams won't hold up long. On my hpi baja 5b ss the front tire foams came one long 2"×2" length was long enough to fit in the tire and had to be glued. Tires were very stiff compared to Xmaxx tires. Not sure how long the layering and gluing will preform or hold up in a soft tire. One peice shape the best you can.

Try calling a foam distributor and explain what you need the foam for and the size. Probably the fast answers for that problem.

See if you can contact a auto motive apulster shop?With the change in size I would try cutting the foam for the bigger part the try and trim the smaller part down to size, maybe new razorblade. You should be able to find sheets of foam the right thickness? Using glue on foams won't hold up long. On my hpi baja 5b ss the front tire foams came one long 2"×2" length was long enough to fit in the tire and had to be glued. Tires were very stiff compared to Xmaxx tires. Not sure how long the layering and gluing will preform or hold up in a soft tire. One peice shape the best you can.

If all you can get are blocks of foam big enough. A electric carving knife should help alot.

Try calling a foam distributor and explain what you need the foam for and the size. Probably the fast answers for that problem.

And if the foams come out good and last. You could start doing foam carving figures for weddings and barmitzvahs? Just a suggestion

Last edited: