Since @SrC and @slick2500 made their own build threads, might as well consolidate my experiences in one thread.

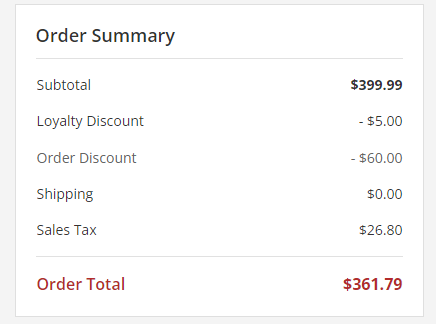

I picked up two Fireteams. One where I got the local Hobbytown to match the Horizon/Tower Hobbies sale prices of $399 in black and I was able to cash in on the Tower Hobbies 15% coupon mess up and order a second one in white for $339:

-------

On the first Fireteam, my tear down found that both droop screw holes are stripped on the front arms and one droop screw hold was stripped on the rear arm. One tire also had a slash/puncture in the sidewall.

Diffs weren’t too bad although the center diff was a little dry.

Sent photos and videos off to Horizon and they’ve already agreed to send replacement parts so I can’t be upset about that.

I decided to make the following upgrades:

1) Upgrade the M4 button head droop screws to actual droop screws. I noticed on my most recent Typhon that Arrma has been using M4 button head screws with washers underneath them to set the droop instead of using the grub screws. I guess this saves on the wear on the chassis, but whomever is putting the button head screws is really cranking down on them and stripping the holes

2) Upgrade the steering tube from a fixed V4 to an adjustable V3. Nice that the Fireteam already comes with the EXB spring.

3) Upgrade the braces to m2c. These have the locator features that are absent on the Arrma EXB braces. Was able to catch the Thanksgiving sale.

4) Upgrade the flanged button head motor mount screws to flanged M4 SHCS from McMaster carr

5) I added fiber washers underneath all the screws on the body. Hopefully this will reduce tear-out of the Lexan pieces. I may replace them with longer screws and nylock nuts if I notice them pulling out of the roll cage

6) Replaced the stock system with a MAX6 combo and used a m2c ESC mount (which provides a place for the switch)

7) Replaced the stock Ackerman with an m2c

8) Replace the RTR servo with a 35kg generic servo

9) Ditch the handbrake system

10) Replaced the 23T servo arm with Hot Racing's direct drive CNC servo arm. Hadn't seen this option before and I like it. A little more simplistic than their aluminum fixed link setup (https://hot-racing.com/?partnumber=AON48E25;c=1535)

11) Replaced various button head screws with socket head screws where possible

I like the Fireteam guys so I'll be keeping them for now.

Here are the threads that pulled out of the arms:

and the puncture in the tire:

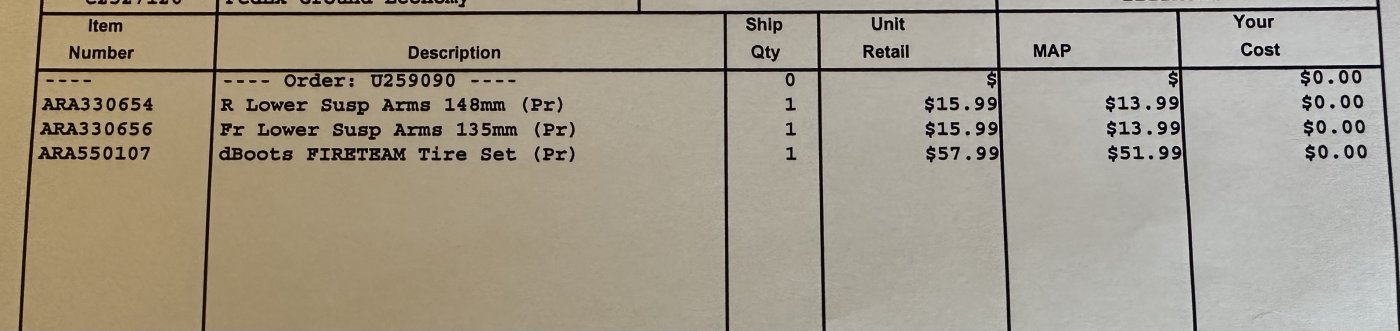

The warranty claim with Arrma was painless. Sent an email with all the information they requested and they had the parts shipped out to me in no time:

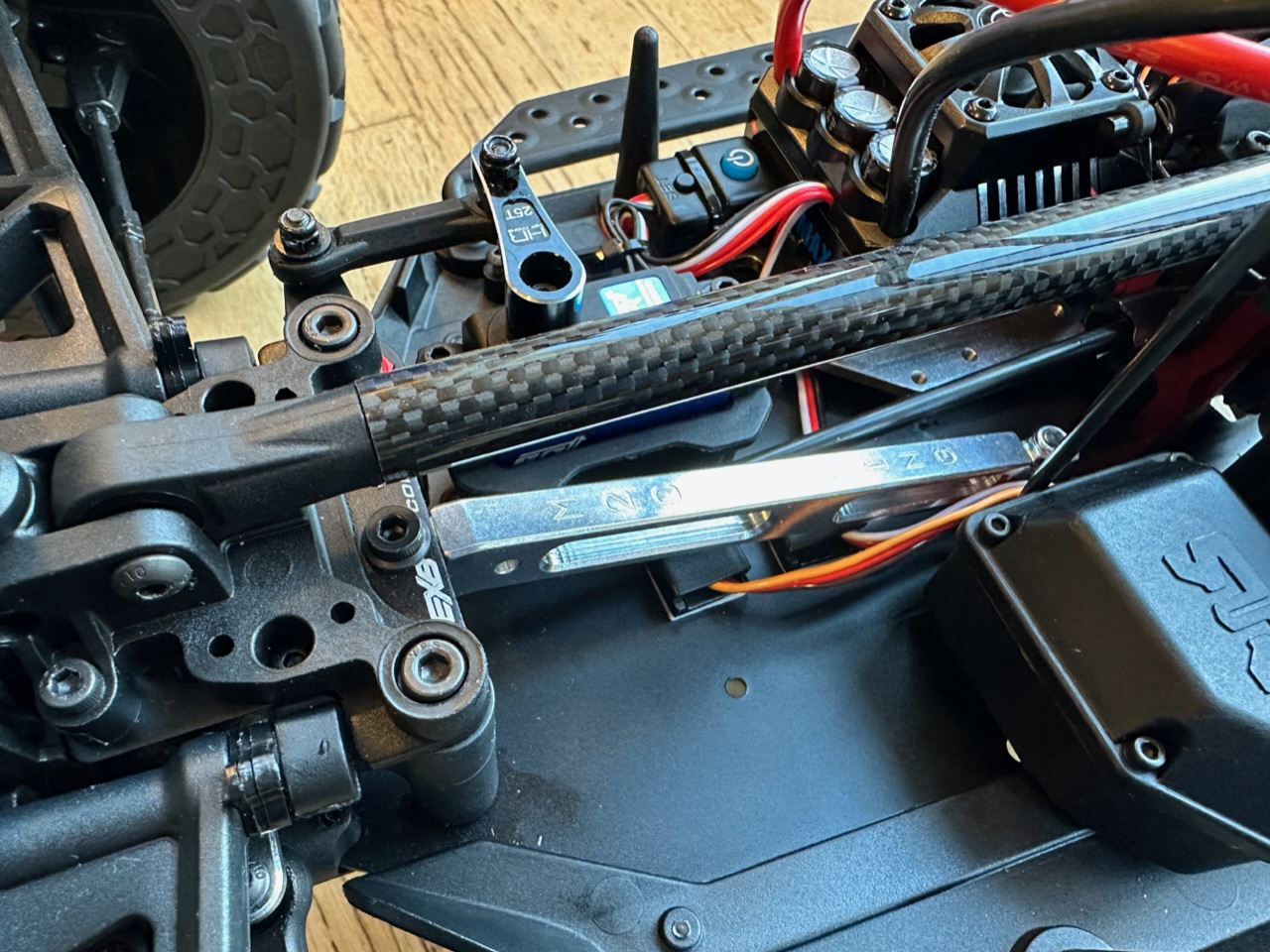

Also I stole @SrC 's idea of sleeving the aluminum tower-to-tower brace with a carbon fiber tube. Cheap and will hopefully work well:

With the m2c ESC plate and the body locating pylon - you have to mount the switch as inboard as possible or else the ring on the body doesn't sit all the way down.

The cat seems rather impressed with my wrenching:

I picked up two Fireteams. One where I got the local Hobbytown to match the Horizon/Tower Hobbies sale prices of $399 in black and I was able to cash in on the Tower Hobbies 15% coupon mess up and order a second one in white for $339:

-------

On the first Fireteam, my tear down found that both droop screw holes are stripped on the front arms and one droop screw hold was stripped on the rear arm. One tire also had a slash/puncture in the sidewall.

Diffs weren’t too bad although the center diff was a little dry.

Sent photos and videos off to Horizon and they’ve already agreed to send replacement parts so I can’t be upset about that.

I decided to make the following upgrades:

1) Upgrade the M4 button head droop screws to actual droop screws. I noticed on my most recent Typhon that Arrma has been using M4 button head screws with washers underneath them to set the droop instead of using the grub screws. I guess this saves on the wear on the chassis, but whomever is putting the button head screws is really cranking down on them and stripping the holes

2) Upgrade the steering tube from a fixed V4 to an adjustable V3. Nice that the Fireteam already comes with the EXB spring.

3) Upgrade the braces to m2c. These have the locator features that are absent on the Arrma EXB braces. Was able to catch the Thanksgiving sale.

4) Upgrade the flanged button head motor mount screws to flanged M4 SHCS from McMaster carr

5) I added fiber washers underneath all the screws on the body. Hopefully this will reduce tear-out of the Lexan pieces. I may replace them with longer screws and nylock nuts if I notice them pulling out of the roll cage

6) Replaced the stock system with a MAX6 combo and used a m2c ESC mount (which provides a place for the switch)

7) Replaced the stock Ackerman with an m2c

8) Replace the RTR servo with a 35kg generic servo

9) Ditch the handbrake system

10) Replaced the 23T servo arm with Hot Racing's direct drive CNC servo arm. Hadn't seen this option before and I like it. A little more simplistic than their aluminum fixed link setup (https://hot-racing.com/?partnumber=AON48E25;c=1535)

11) Replaced various button head screws with socket head screws where possible

I like the Fireteam guys so I'll be keeping them for now.

Here are the threads that pulled out of the arms:

and the puncture in the tire:

The warranty claim with Arrma was painless. Sent an email with all the information they requested and they had the parts shipped out to me in no time:

Also I stole @SrC 's idea of sleeving the aluminum tower-to-tower brace with a carbon fiber tube. Cheap and will hopefully work well:

With the m2c ESC plate and the body locating pylon - you have to mount the switch as inboard as possible or else the ring on the body doesn't sit all the way down.

The cat seems rather impressed with my wrenching:

Last edited: