Got my Limitless to Infraction build finished.

It went slow because of delivery times but it is finally ready to see some road time. I just need to find a proper paved area.

It started with the Limitless roller. Walked into my lhs and grabbed it off the shelf. It was the last one too. I also grabbed some arrma exabyte buggy tires because I had an intention of running the infraction on low grass every now and then.

My first batch of parts came in one package. Infraction body, infraction hoons, bumper set and center diff 46t with arrma aluminum diff cups f/c/r.

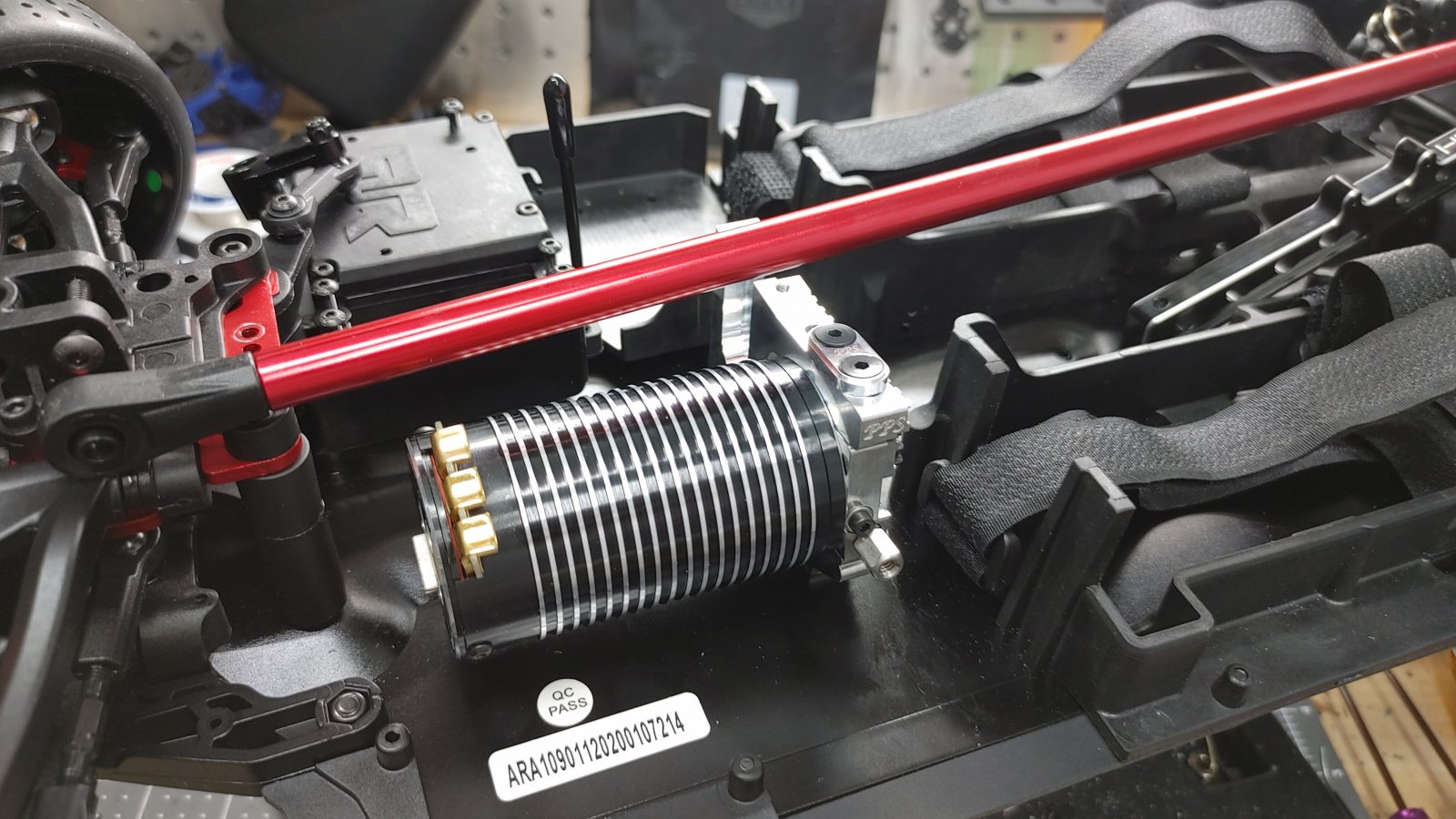

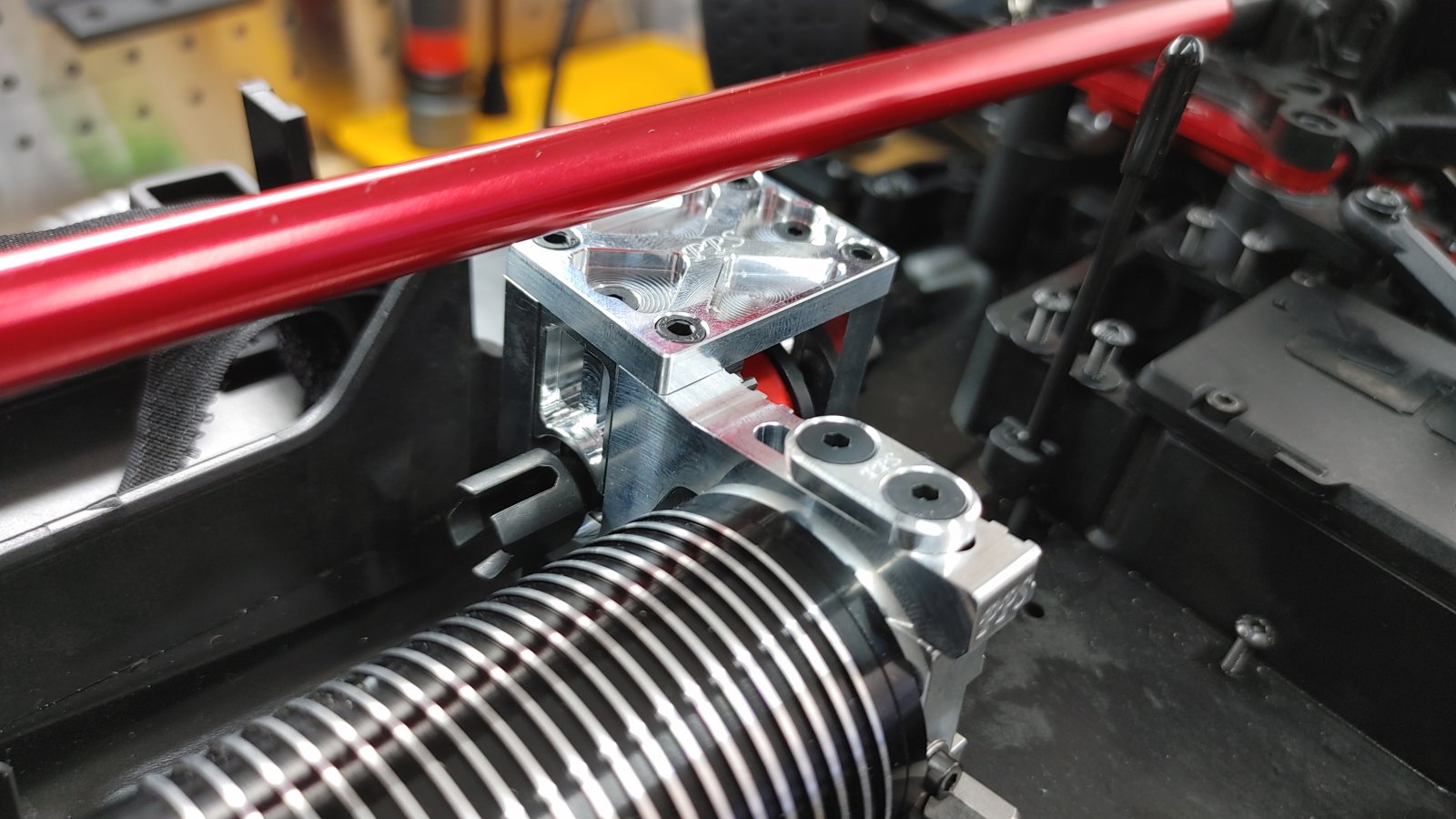

Next parts to get installed were the hot racing center braces, the pps motor mount and rear cvds. Arrma loctite didn't disappoint. Even with heat I had to resort to my screw extractor. Luckily I had extra screws from my kraton6s bulkhead upgrade.

While waiting for more parts I decided to try the motor relocation. I also got my pps center section. And I had finished the center diff with the arrma aluminum diff cup.

It required a battery tray removal. For some reason I just didn't like the "look" so I went back to the dual battery tray configuration.

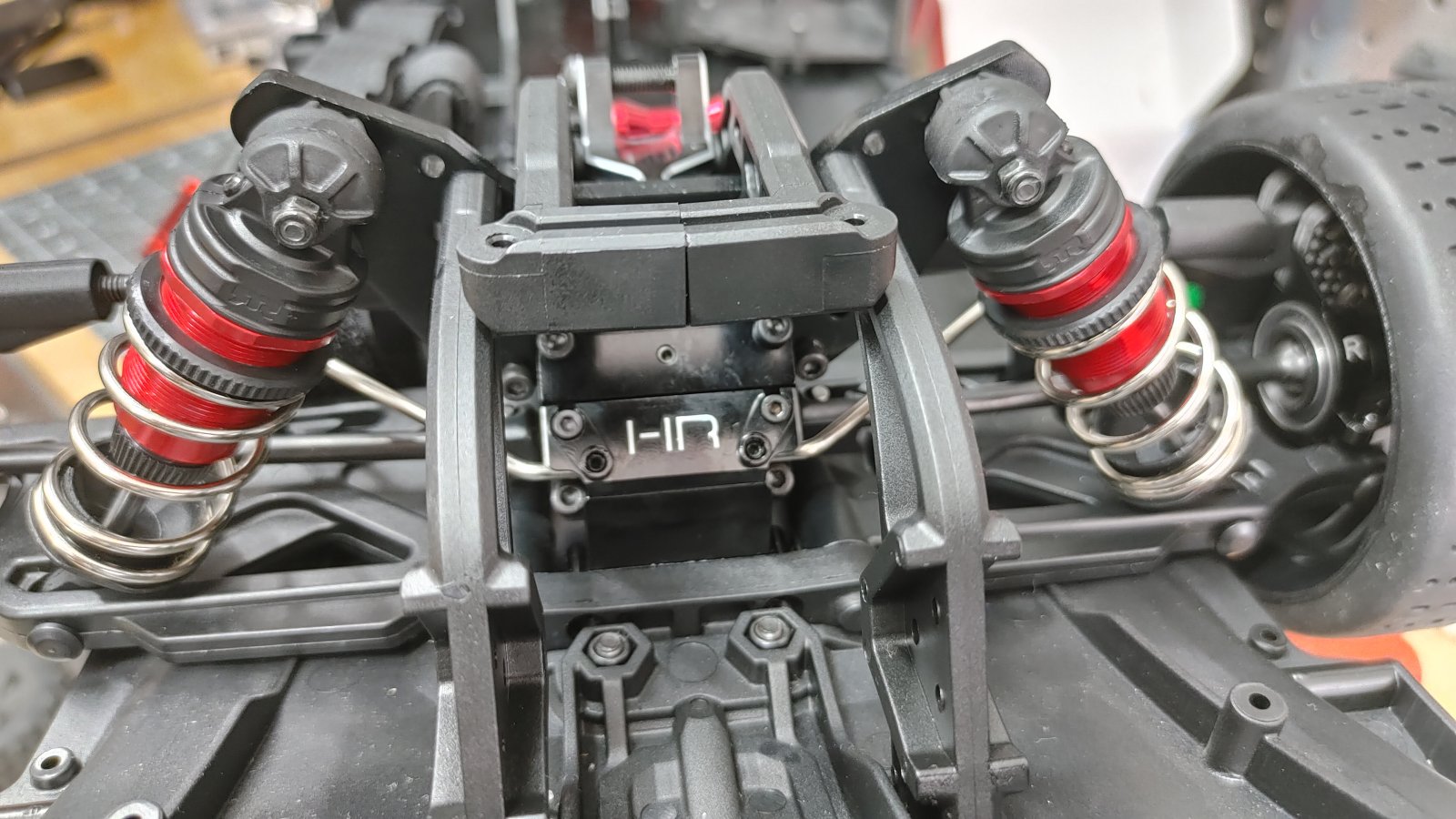

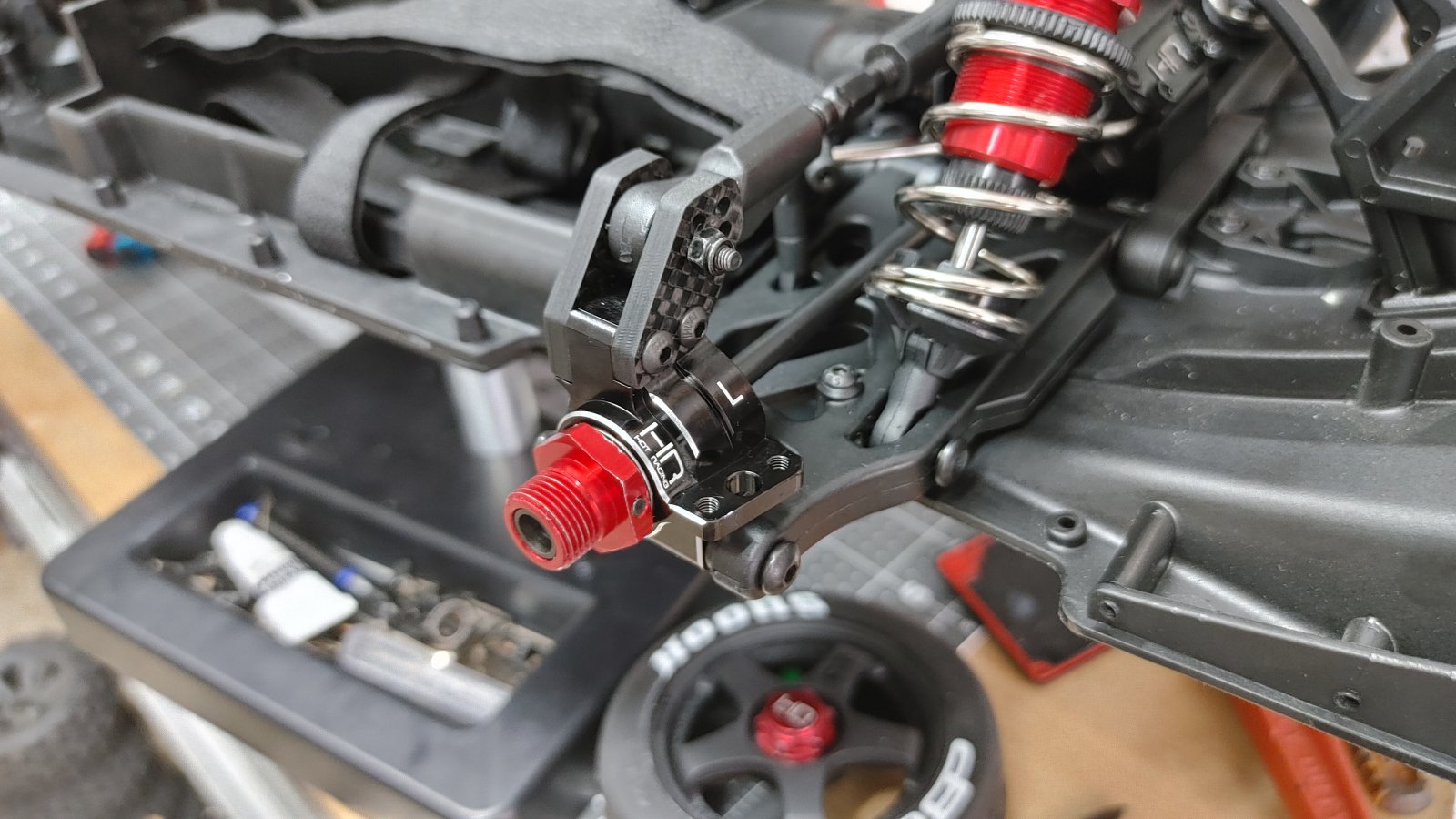

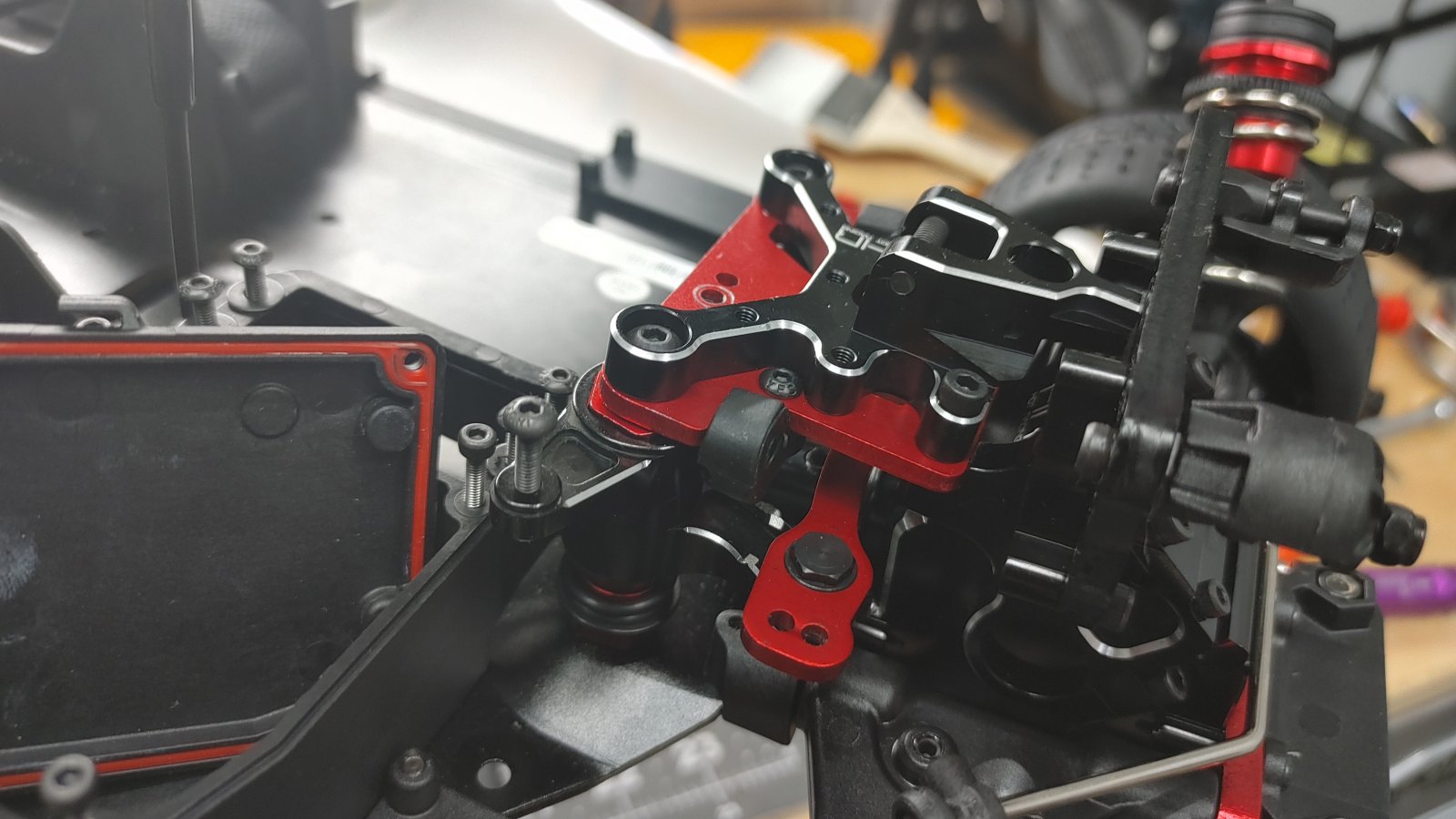

More parts trickled in. Hot racing bulkheads, bulkhead covers, sway bar covers, steering hubs and rear hubs,

servo mount, t2t braces and steering rack.

Waiting on some other parts I decided to clean up the shock slop like I did on my kraton6s. Luckily the same half bushings worked.

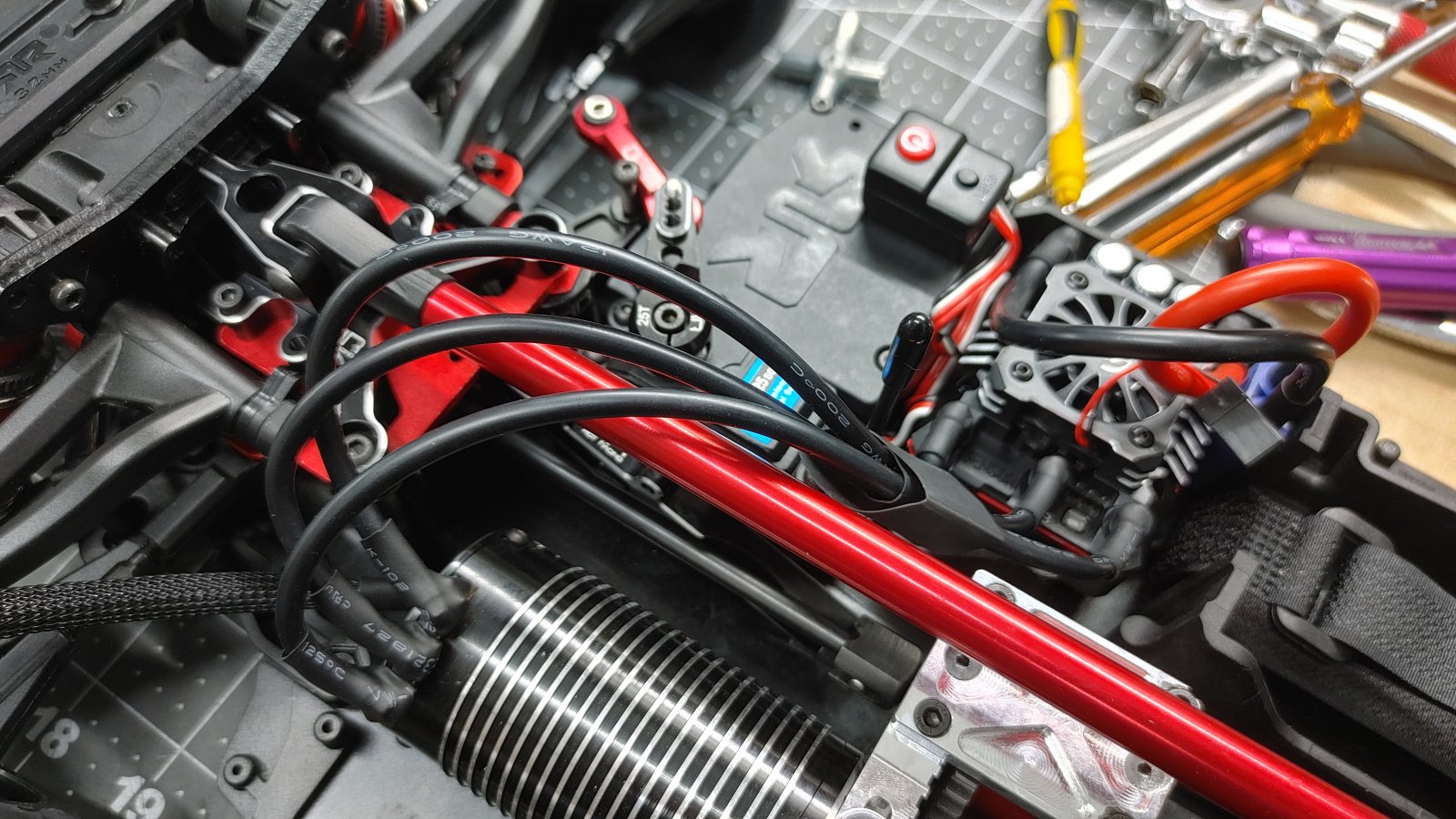

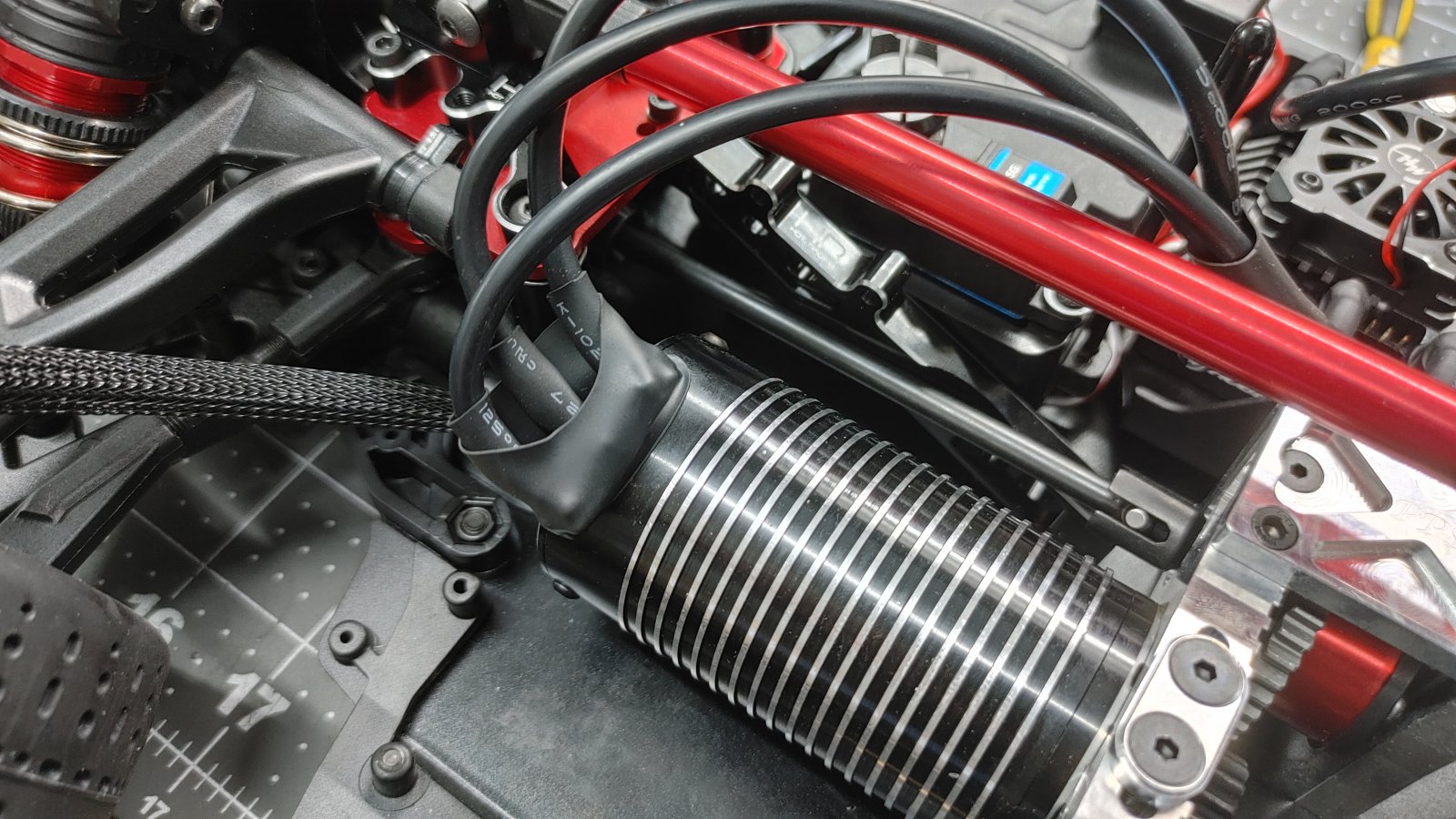

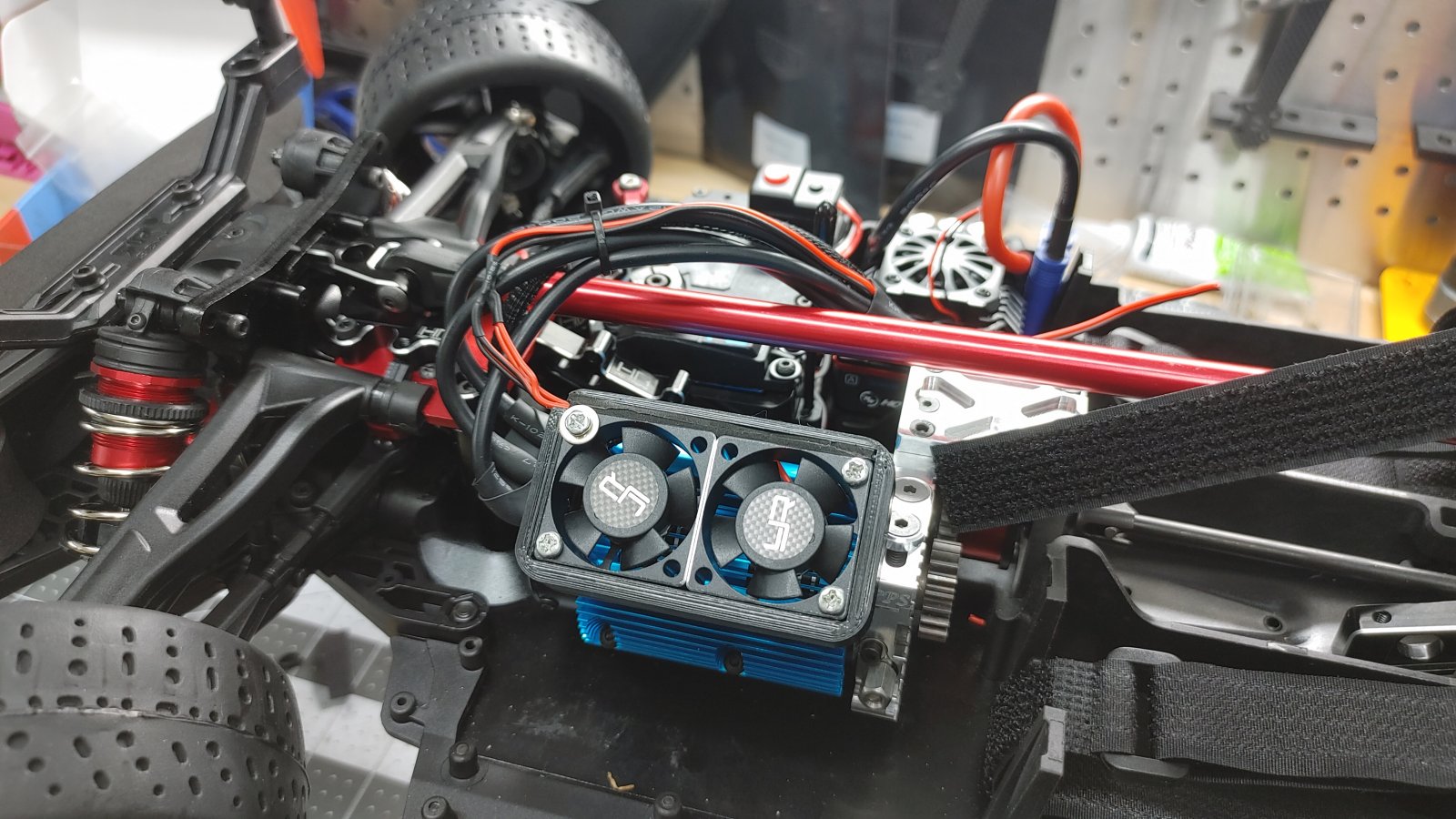

Finally decided to mount the esc and servo after the servo got delivered. Did quick work with soldering the battery lead and motor wires. I also installed the yeah racing heatsink with the aluminum tornado fans.

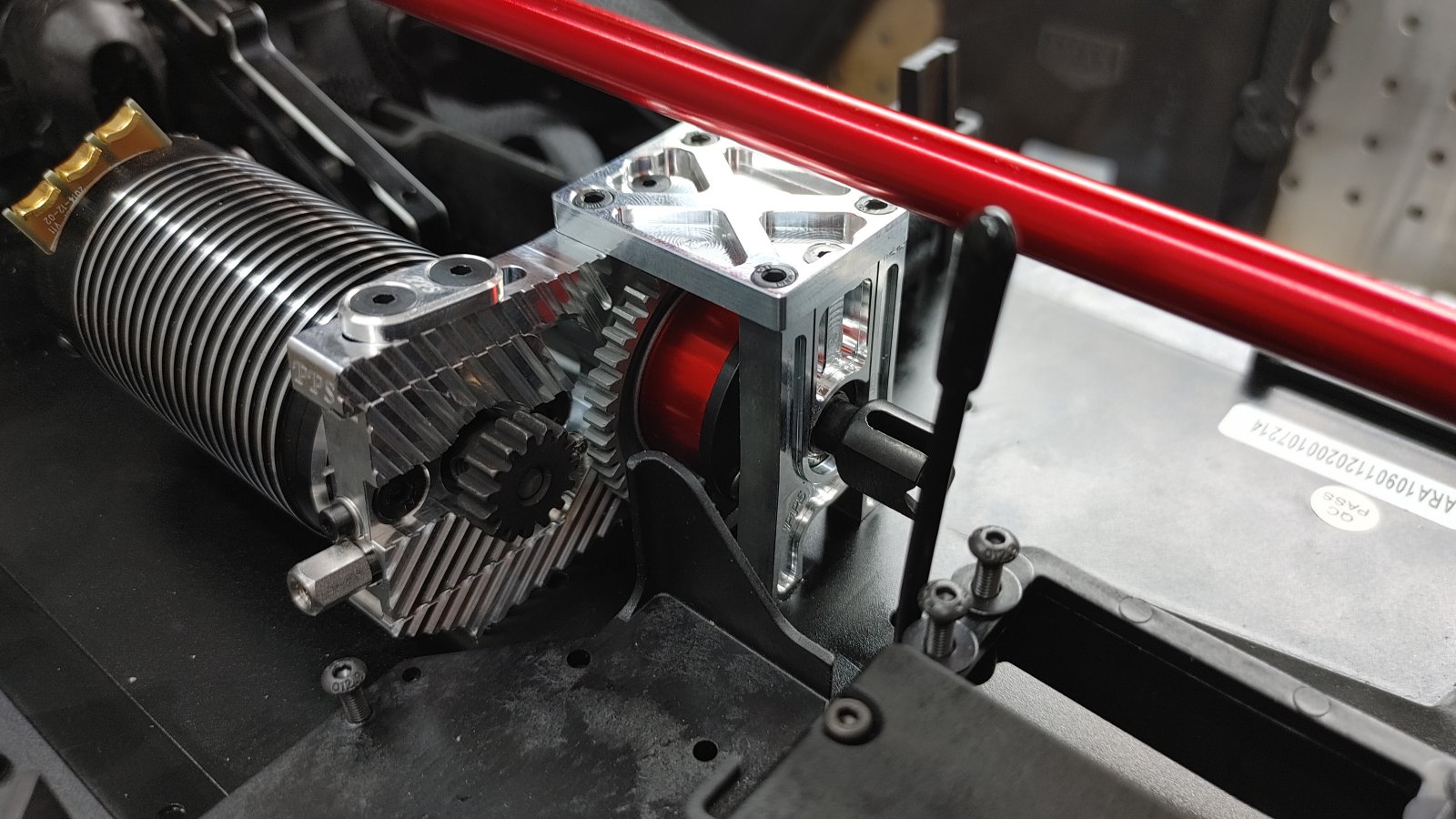

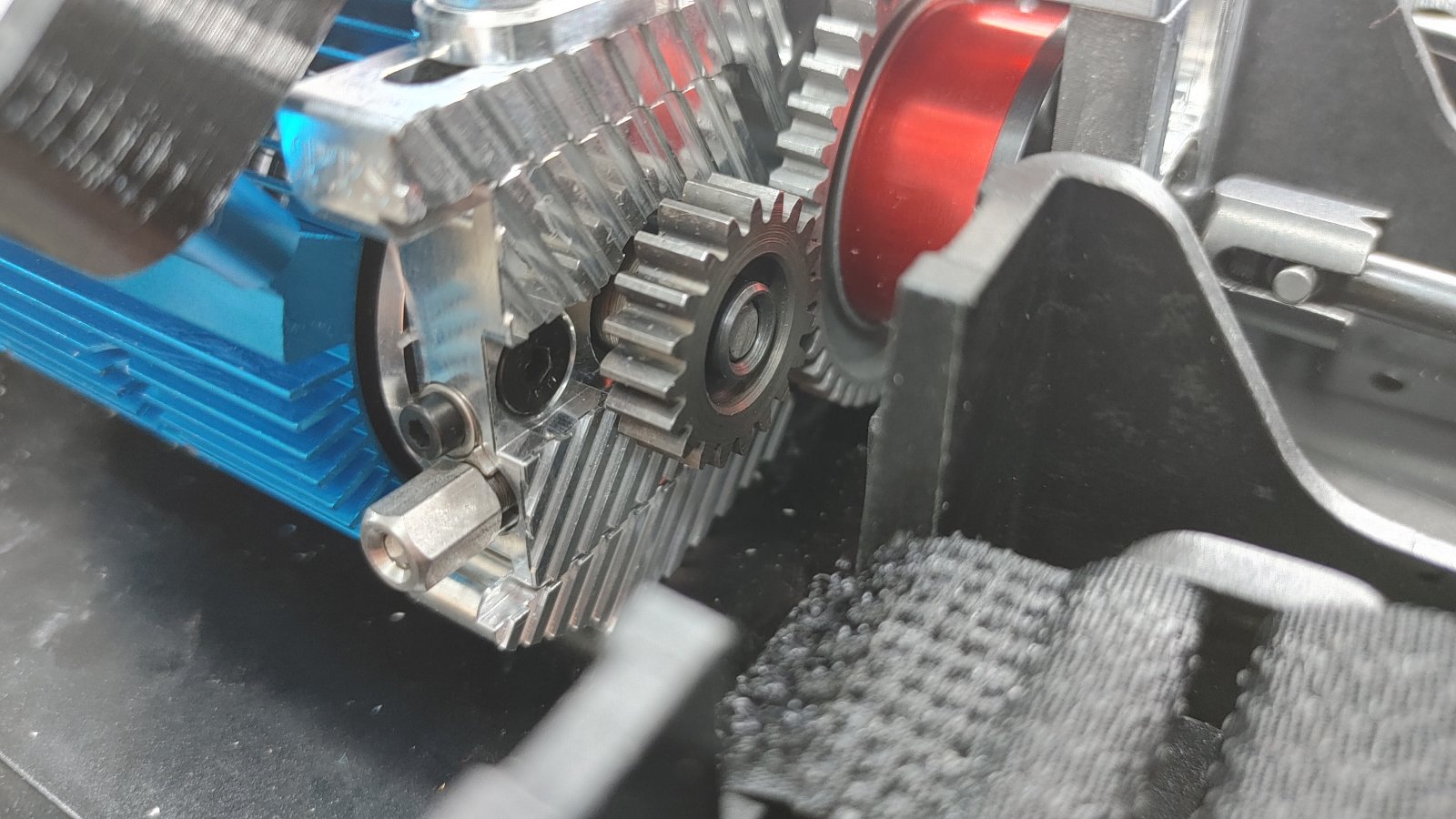

I installed a 20t pinion. Stock infraction is 18t with a 46t center diff.

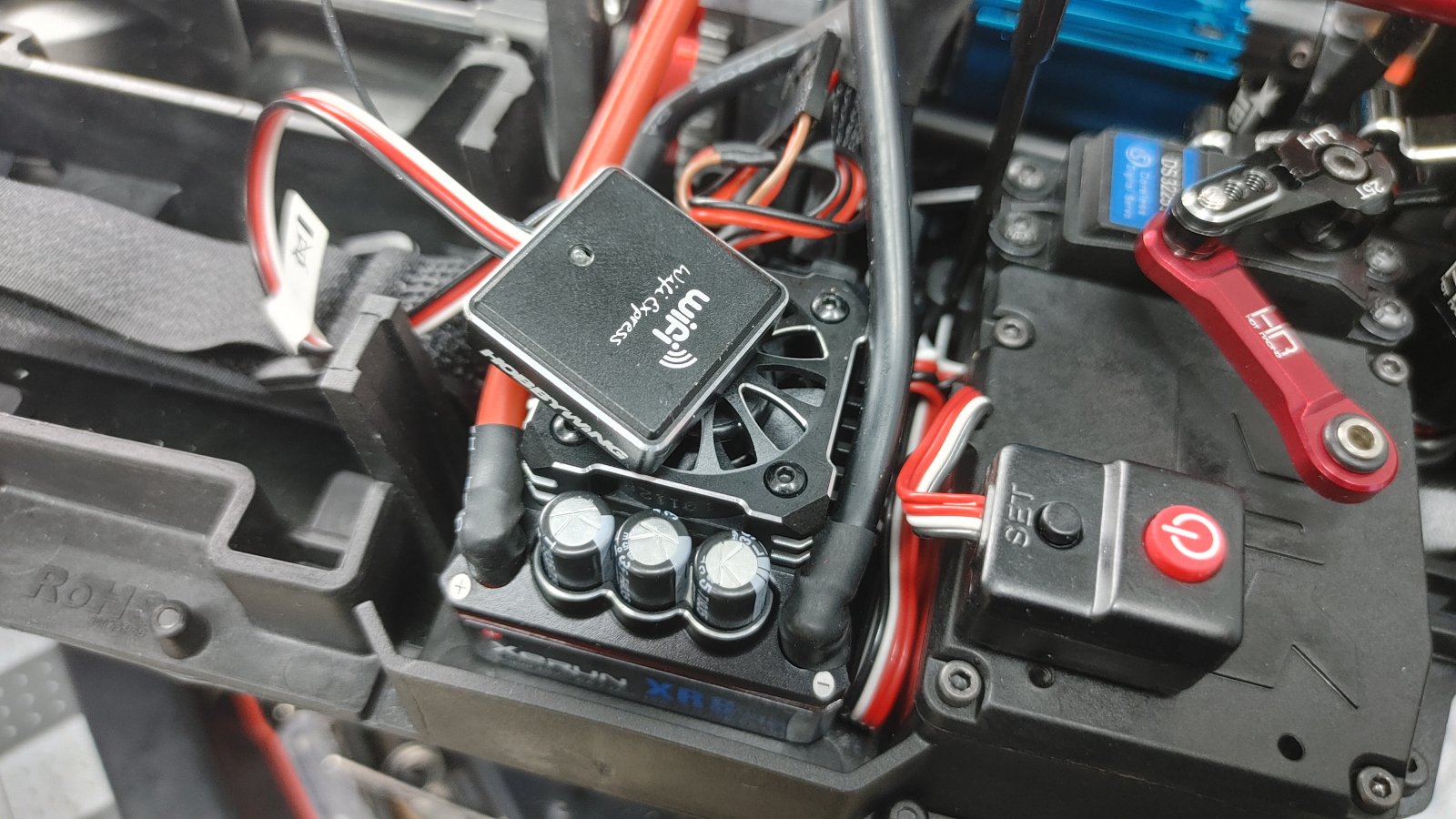

On to the esc. Updated the firmware first and then programmed the settings.

Calibrated, set the endpoints for the servo and tested motor direction. Everything checked out.

Moved on to the last item, the shocks. I got the aluminum pieces to complete the shock set.

Need some shock oil. 2000cst stock.

Gotta re-use the bladder on the aluminum caps. Carefully removed with some hobby tweezers.

The stock pistons installed are the 1.2mm hole pistons.

Shock assembly

And back together

Time to join the hoon tire burning club ?

It went slow because of delivery times but it is finally ready to see some road time. I just need to find a proper paved area.

It started with the Limitless roller. Walked into my lhs and grabbed it off the shelf. It was the last one too. I also grabbed some arrma exabyte buggy tires because I had an intention of running the infraction on low grass every now and then.

My first batch of parts came in one package. Infraction body, infraction hoons, bumper set and center diff 46t with arrma aluminum diff cups f/c/r.

Next parts to get installed were the hot racing center braces, the pps motor mount and rear cvds. Arrma loctite didn't disappoint. Even with heat I had to resort to my screw extractor. Luckily I had extra screws from my kraton6s bulkhead upgrade.

While waiting for more parts I decided to try the motor relocation. I also got my pps center section. And I had finished the center diff with the arrma aluminum diff cup.

It required a battery tray removal. For some reason I just didn't like the "look" so I went back to the dual battery tray configuration.

More parts trickled in. Hot racing bulkheads, bulkhead covers, sway bar covers, steering hubs and rear hubs,

servo mount, t2t braces and steering rack.

Waiting on some other parts I decided to clean up the shock slop like I did on my kraton6s. Luckily the same half bushings worked.

Finally decided to mount the esc and servo after the servo got delivered. Did quick work with soldering the battery lead and motor wires. I also installed the yeah racing heatsink with the aluminum tornado fans.

I installed a 20t pinion. Stock infraction is 18t with a 46t center diff.

On to the esc. Updated the firmware first and then programmed the settings.

Calibrated, set the endpoints for the servo and tested motor direction. Everything checked out.

Moved on to the last item, the shocks. I got the aluminum pieces to complete the shock set.

Need some shock oil. 2000cst stock.

Gotta re-use the bladder on the aluminum caps. Carefully removed with some hobby tweezers.

The stock pistons installed are the 1.2mm hole pistons.

Shock assembly

And back together

Time to join the hoon tire burning club ?

Last edited: