- Messages

- 10,104

- Reaction score

- 24,864

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

For those of you who follow me on YouTube the cat is out of the bag...

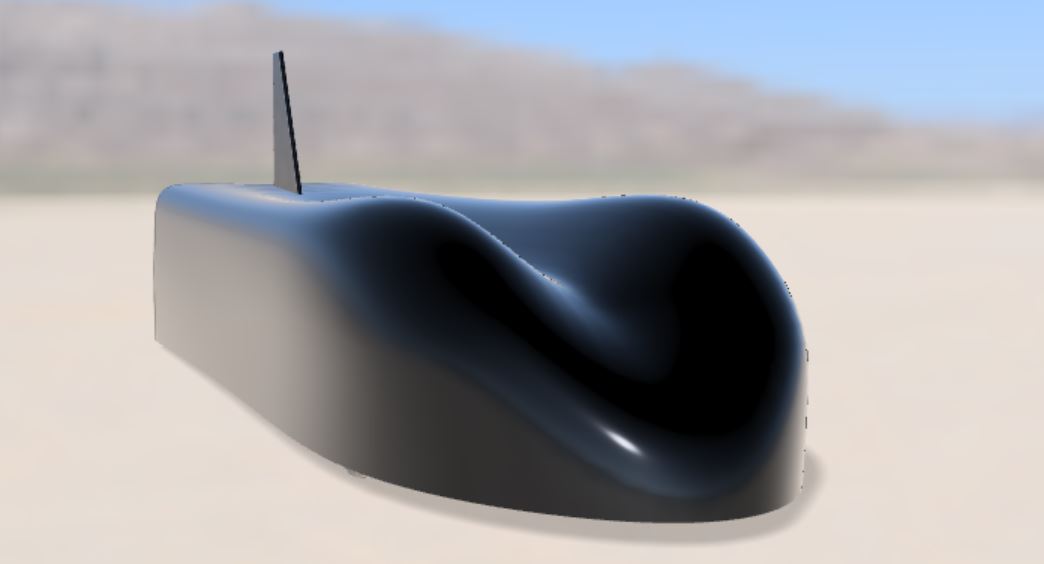

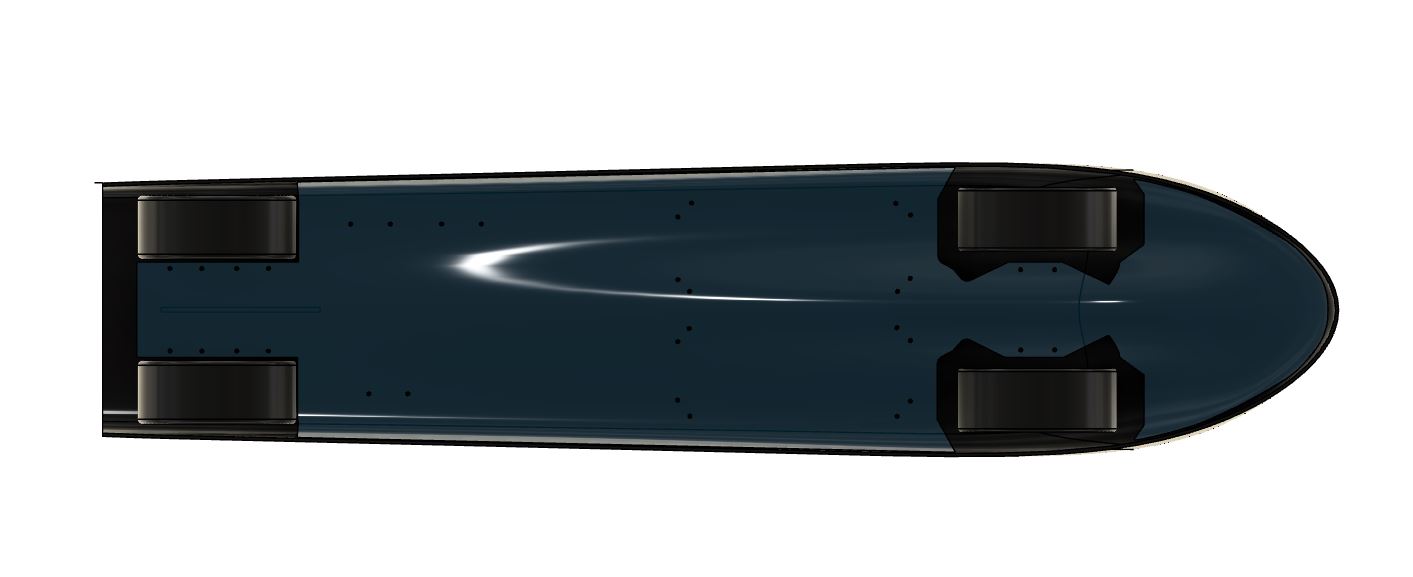

I am making a 100% custom car with the goal of 200+ mph! This will be my final build as I want to get back into 1:1 cars.

The plan is to go see my local CNC guy in the next week or two and take my 3d print mock up to be made in aluminum for the motor mounts and bearing carriers. The lower and upper chassis will be carbon fiber. The body will be carbon fiber also (more on that later)

Here is a few renderings of the car in completed form:

I am making a 100% custom car with the goal of 200+ mph! This will be my final build as I want to get back into 1:1 cars.

The plan is to go see my local CNC guy in the next week or two and take my 3d print mock up to be made in aluminum for the motor mounts and bearing carriers. The lower and upper chassis will be carbon fiber. The body will be carbon fiber also (more on that later)

Here is a few renderings of the car in completed form:

Last edited: