Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Soooo it’s safe to say that....

- Thread starter 2015GTRBE

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I lost track of how many arms BB has been through. Yeah RPM's if its a priority for them right now.

I don't have a K8 yet. But watching very closely what the upgrade necessities will be.

M2C SWB chassis for sure. IMO. It should have been a SWB OC/Noto 8S rig to begin with.

Then arms whoever does them first. Bent shock shafts and rod ends. The cracking wheels seem to be a problem too. But very cold temps contribute much to the plastic issues? 1/5 big air Bashing seems to be new territory.

I don't have a K8 yet. But watching very closely what the upgrade necessities will be.

M2C SWB chassis for sure. IMO. It should have been a SWB OC/Noto 8S rig to begin with.

Then arms whoever does them first. Bent shock shafts and rod ends. The cracking wheels seem to be a problem too. But very cold temps contribute much to the plastic issues? 1/5 big air Bashing seems to be new territory.

bicketybam

Back from vacation!

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 13,394

- Reaction score

- 23,196

- Location

- New Milford, CT

- Arrma RC's

- BigRock 4x4

- Granite

- Infraction

- Kraton 8S

- Kraton 6s

- Kraton 4s

- Mojave

- Notorious

- Talion

- Typhon 6s

I've broken a total of 4 arms: two front lowers and two rears. Both fronts are on me. I ran it into my fire pit for one breakage and dropped it out of the sky onto the front wheel for the other. The rears (both the same side) were just from my normal bashing.

Time for RPM to come out with some

https://www.arrmaforum.com/threads/rpm-bad-news-for-now.17859/

I've snapped RPM in cold weather too. You have the cold combined with the trucks speed = wind chill = carnage. On a side note, the upper and lower a-arm holes through the hinge pin's sloppy tolerance outa the box is not helping the rigidity much IMO.. Every one of them seemed to have it I looked at in the LHS's.

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,411

- Reaction score

- 21,626

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4

We all need to start sending RPM 5 emails a day until they release some...

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

How about letting Arrma know about the Arms too. They should be revised IMO. The plastic composition and all.

In this case I don't feel we can exclusively rely on RPM. I wouldn't hold my breath, that's all.

It may be a while. Hope not.

In this case I don't feel we can exclusively rely on RPM. I wouldn't hold my breath, that's all.

It may be a while. Hope not.

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,411

- Reaction score

- 21,626

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4

Ok, let’s all send Arrma and HH 5 emails a day then... ?

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I would do that. Seriously speaking. They do listen. Unlike TRX.

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,411

- Reaction score

- 21,626

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4

Someone should make a proper email that we can all copy and paste to send them.

Maybe then they will get the hint... ?

I’m not very good at not being vulgar. ?

Even if they offered an upgraded set, I’d be fine with purchasing them.

Maybe then they will get the hint... ?

I’m not very good at not being vulgar. ?

Even if they offered an upgraded set, I’d be fine with purchasing them.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Sometimes un published revisions are made without us even knowing. Sometimes QC is addressed at production during Mfr.

And we end up with better parts. Slop at the arms hinge pin holes should be addressed for instance. Maybe its a plastic molding issue?

And it is costly to revise the plastics composition mid production.

Arrma and HH should know the end users complaints with any new model. Users are the ultimate test bed. Right?

And we end up with better parts. Slop at the arms hinge pin holes should be addressed for instance. Maybe its a plastic molding issue?

And it is costly to revise the plastics composition mid production.

Arrma and HH should know the end users complaints with any new model. Users are the ultimate test bed. Right?

Hotwheel85

Active Member

- Messages

- 164

- Reaction score

- 120

- Arrma RC's

- Kraton 8S

I sent them mail about this for a week ago or so. So i hope everyone else here that is interested sending them request.

This is the mail adress i got answer from

[email protected]

The answer was that they just got a k8s and they will test and look into it. Question would be if rpm arms make it stronger or if they just make another part to break.

This is the mail adress i got answer from

[email protected]

The answer was that they just got a k8s and they will test and look into it. Question would be if rpm arms make it stronger or if they just make another part to break.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,880

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Arms by themselves breaking is one thing. But usually there is more carnage than meets the eye. Like bent drive shafts/cvd's and pins shock rods and ends and all other closely related parts. That's the big concern with broken arms in general. Broken arms can create a big repair bill when you factor in all the related parts that can and will break during an Arm failure.

Against my better judgement, I am starting to feel that billet $7075$ alloy arms may be the best alternative material for 1/5. But, not counting RPM out of the picture just yet.

Against my better judgement, I am starting to feel that billet $7075$ alloy arms may be the best alternative material for 1/5. But, not counting RPM out of the picture just yet.

Last edited:

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,411

- Reaction score

- 21,626

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4

Losi which is also under the HH umbrella. Had a similar issue recently with the Mini-T 2.0 and the front control arms. They were snapping at the pin constantly. Losi then quickly made a revised edition, now if you call HH they will send you the new revised set free of charge. Which are much stronger. I haven’t broken the new ones yet and I pound the piss out of it every night! ?

So, how many of you emailed them today?

- Messages

- 2,023

- Reaction score

- 3,746

- Arrma RC's

- BigRock

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Mojave

- Mojave EXB

- Nero

- Notorious

- Outcast 8s

- Outcast 6s

- Senton 6s

- Talion

I'm on that boat as well, but alum arms alone will destroy bulkheads & break stock hinge pin holders. It would be seriously expensive, but alum bulkheads would be a must with alum arms . . . but the K8S fund is buffed up enough to buy a 2nd one so I'm rdy for all upgrades. The rolly polly plastic RPM uses will simply flex to hell & bend CVDs with just that, even the junk Arrma uses can flex enough to bend them if it's hot out. I'll take a page out of my first DBXL-e that I upgraded with all the alum stuff until it turned into a shelf queen & I bought another. It's by far the toughest big car I own, but every time I look at it, I want to put it under glassArms by themselves breaking is one thing. But usually there is more carnage than meets the eye. Like bent drive shafts/cvd's and pins shock rods and ends and all other closely related parts. That's the big concern with broken arms in general. Broken arms can create a big repair bill when you factor in all the related parts that can and will break during an Arm failure.

Against my better judgement, I am starting to feel that billet $7075$ alloy arms may be the best alternative material for 1/5. But, not counting RPM out of the picture just yet.

His-n-hers

Member

- Messages

- 55

- Reaction score

- 57

- Arrma RC's

- Kraton 6s

i have not purchased the 8s yet due to weather and the hours i work. waiting till spring, I was wondering if they had not cut out so much material to save weight i guess. would these arms be less likely to fail?

3d-rc.myshopify.com

Eat,sleep and breath Arrma

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 6,198

- Reaction score

- 11,378

- Location

- Michigan

- Arrma RC's

- BigRock 4x4

- Granite

- Infraction

- Kraton 8S

- Kraton 6s

- Notorious

- Senton 6s

- Senton 3s

I wonder if someone is willing to fill the voids in a arms with an epoxy or a resin. Have we noted if there is a common area where they are prone to breaking?

bicketybam

Back from vacation!

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 13,394

- Reaction score

- 23,196

- Location

- New Milford, CT

- Arrma RC's

- BigRock 4x4

- Granite

- Infraction

- Kraton 8S

- Kraton 6s

- Kraton 4s

- Mojave

- Notorious

- Talion

- Typhon 6s

The two rears I broke snapped in the same area, close to the pin.I wonder if someone is willing to fill the voids in a arms with an epoxy or a resin. Have we noted if there is a common area where they are prone to breaking?

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,839

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

I would try adding some CF sheets where possible. I know other brands have this as an option to stiffen and strengthen their arms.

- Messages

- 620

- Reaction score

- 801

- Arrma RC's

- Limitless

- Kraton 8S

- Kraton 6s

- Typhon 6s

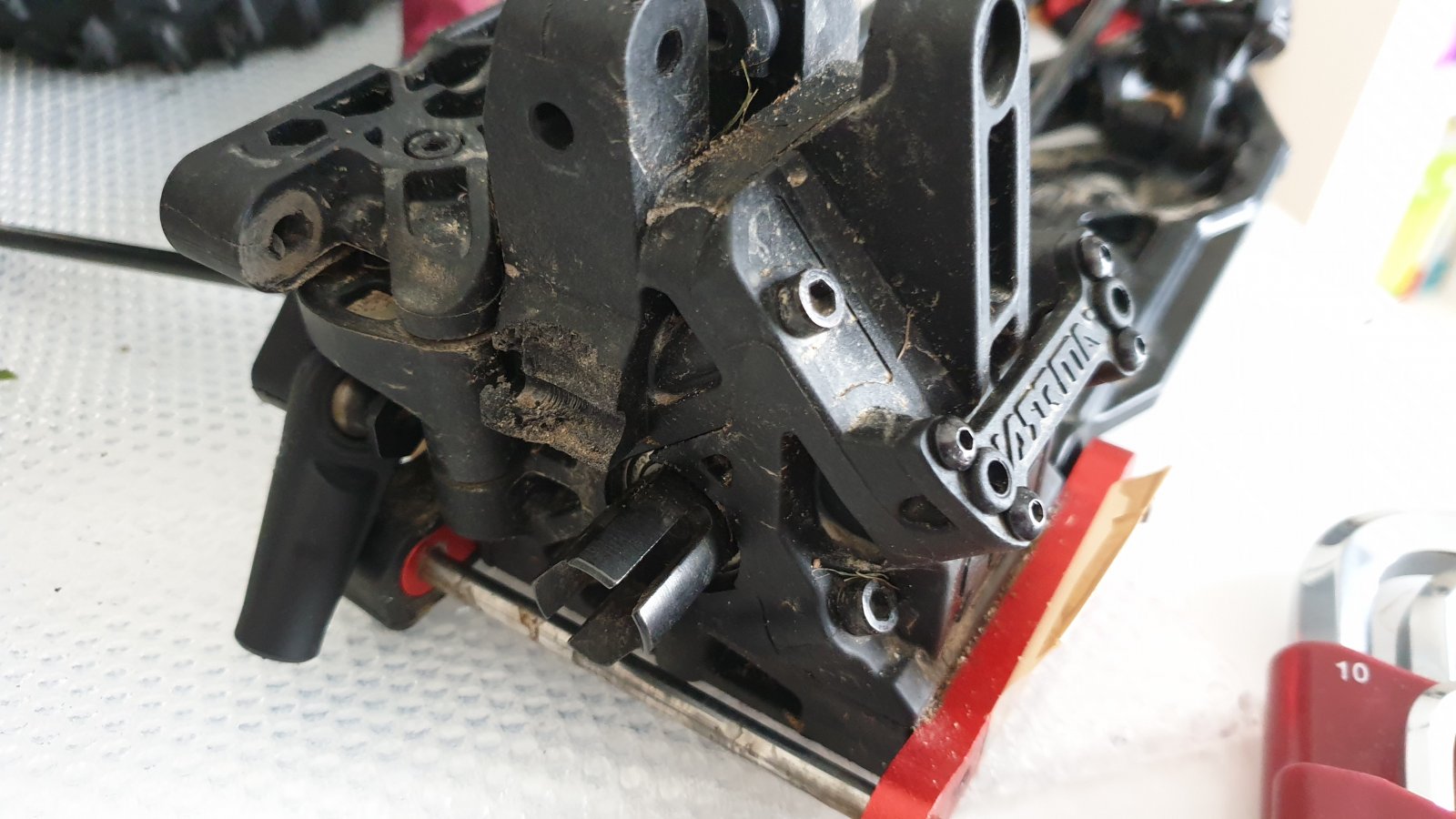

Mine snapped right at the pin, though it wasn't the fault of the arm but the sheer force of the impact. Killed the pin, the lower a-arm, the shock tower, part of the front bumper and the bulkhead while also bending the shock shaft

Similar threads

- Replies

- 1

- Views

- 318

- Replies

- 26

- Views

- 1K