Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Talion Talion exb outdrive cup

- Thread starter Grocery Ninja

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Dan B.

Area man

Lifetime Premium!

Premium Member

ArrmaForum Fan

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,390

- Reaction score

- 17,199

- Location

- Southern Vermont

- Arrma RC's

- Fireteam

- Granite

- Limitless

- Mojave EXB

- Notorious

- Outcast 6s

- Typhon 6s

I agree, but in the world of RC now (mostly preassembled RTR’s) that’s to be expected, unfortunately. FWIW, I never ever run a rig without first checking gear mesh, wheel hexes and nuts, or without setting endpoints. I manually manipulate the diffs (outdrives and input cups) to make sure they’re not way out of whack and if they’re close to ok I run a couple or three packs through before I remove, reshim, and refill. New gears need to “run in” IMO, unless you just want to do it twice in a very short amount of time. Could they be perfectly assembled at the factory by teams of skilled, knowledgeable workers? Of course they could, and the price would likely double. Back in the day when it was you building the thing from a box of parts with a great assembly manual, then you knew what every clearance was, and every nut and bolt was good when you were done.I calibrated the esc and the front was drooping a little so I did a little adjustment to the shocks to get it off the ground. The end points were short if anything so I didn't mess with them. Am I the only one who thinks it's a bit silly to have to tear an almost $1000 machine apart in order to even use it? Would you tolerate that with your TV, phone or any other thing that's relatively high grade? I understand that wrenching is part of the fun but it isn't THE fun. Driving is THE fun. If this is the norm we as a group are tolerating too much mediocrity from Arrma.

ThisWe NEED kits.

I understand you are frustrated your toy broke on the first outing, I would be too.I calibrated the esc and the front was drooping a little so I did a little adjustment to the shocks to get it off the ground. The end points were short if anything so I didn't mess with them. Am I the only one who thinks it's a bit silly to have to tear an almost $1000 machine apart in order to even use it? Would you tolerate that with your TV, phone or any other thing that's relatively high grade? I understand that wrenching is part of the fun but it isn't THE fun. Driving is THE fun. If this is the norm we as a group are tolerating too much mediocrity from Arrma.

But the cups don't just miraculously explode if they were not faulty from the beginning.

Maybe this is your first 6s car and you abused the car? Even stock they have more than enough power to destroy themselves if the driver is not used to it or is just completly ignorant to mechanical limits or whatever you wanna call it.

Not saying that's what happend, but many of these "my car broke on the first drive" posts never actually go into detail about how it happend, just that it is the first drive and that should not happen to such an expensive toy...kinda sus.

Doesn't matter if it's the first or 100th drive, if you take a hit or land wrong something might break. It's how it is.

For what its worth, I drive all my cars right out of the box without going through them.

Never had a problem except maybe some accelerated wear on some parts and a loose screw or wheelnut here and there.

It's not because I don't know better, I just don't care.

Try to keep in mind that people usually only post if something goes wrong and this forum is a very limited sample size.

These are still massproduced toys, assembled by underpaid and unmotivated people under questionable conditions...

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Many new to this don't even remember what happend when it first broke. The shock and awe took over. Then the disappointment unravels.

TBH, the only error here aside from understanadable newb driver error is that the diffs should have been overhauled first. Or at least checked. Its always when new this truly happens. These rigs are not really RTR until you bless it first with hex driver in hand. Never broke a Drive cup before. Mine just wear out normally. Throttling under loads and hard landing, or when crashing is what does this also. Is what it is. Take your pick.

Take your pick.

M2C drive cups are better. Harder steel. For a similar price. Just they wear better. But anything can break if abused well enough. I wouldn't expect HH to always step up, due to driver error. To each his own.

TBH, the only error here aside from understanadable newb driver error is that the diffs should have been overhauled first. Or at least checked. Its always when new this truly happens. These rigs are not really RTR until you bless it first with hex driver in hand. Never broke a Drive cup before. Mine just wear out normally. Throttling under loads and hard landing, or when crashing is what does this also. Is what it is.

M2C drive cups are better. Harder steel. For a similar price. Just they wear better. But anything can break if abused well enough. I wouldn't expect HH to always step up, due to driver error. To each his own.

Grocery Ninja

Member

- Thread starter

- #25

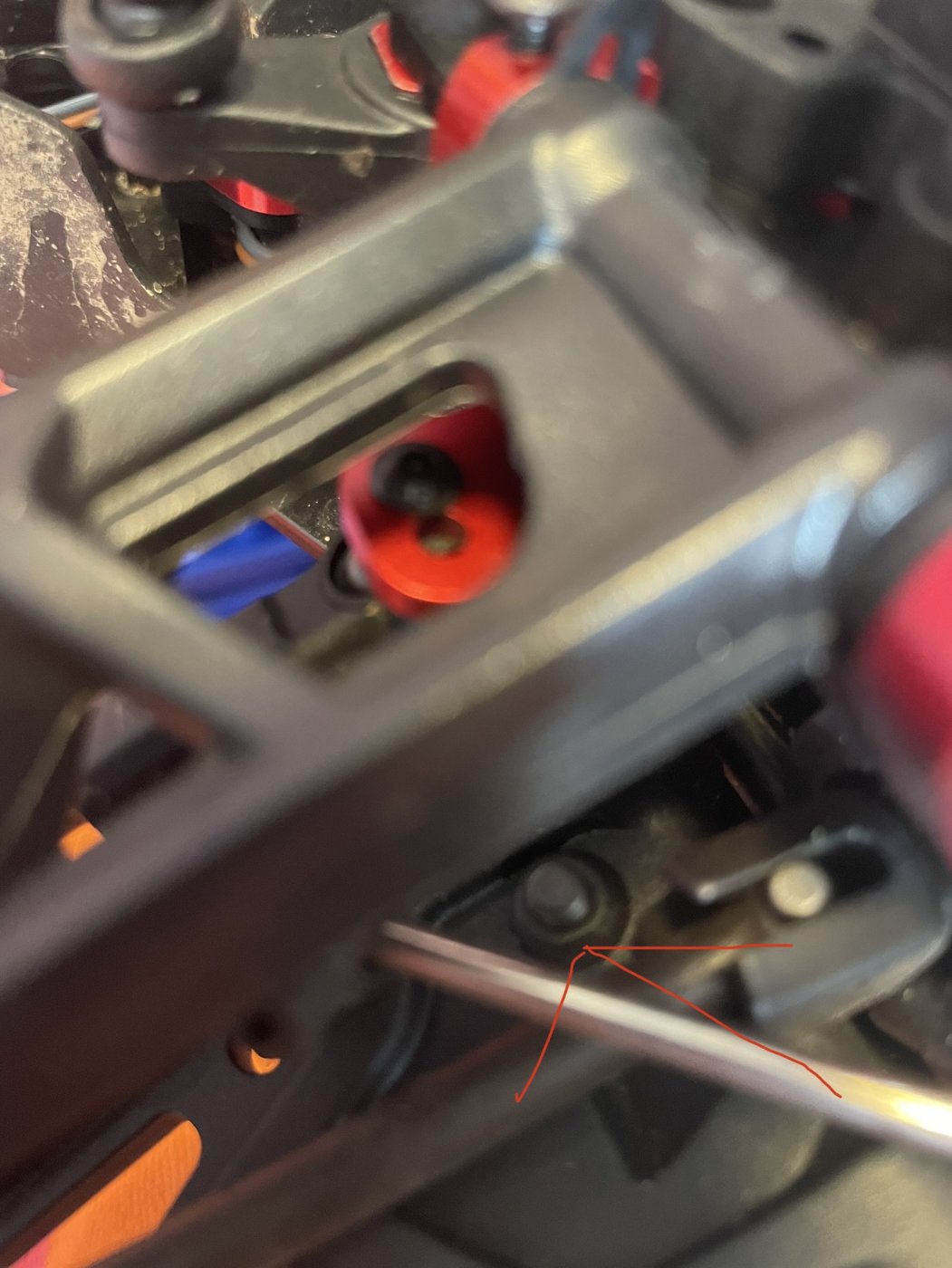

Thank you so much everyone, I absolutely love all of the engagement in this forum. A little update. HH sent me a new set of cups, the front diff looked awesome and was tight as a drum. I put 50k oil back in it and it drives awesome. I ran two packs through it at a park in the freshly mowed grass and on a long dirt driveway and it's so fast and controllable. I'll probably put some heavier fluid in the rear next time I have stuff apart. I think they put the wrong droop screws in because if the rounded head is down toward the chassis there's no way to adjust them. I attached a picture. After doing some research I found some that have a hex in the other end too, so I have those on the way.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Yeah Arrma cheaped out on the Droop Screws. Actually they aren't even Droop screws per se. Just plain M4 screws. All Legit droop screws will have a legit "Broached hex" on the threaded end, accessed above the arm for easy adjustments.  The correct way. Arrma does sell them separately . I use them. You get like 8 of them for 2 Models. But on many of my models, I also use the Avid Titanium Domed droop screws. 1/8 track crowd use these exclusively. The smooth button head (no hex) prevents gouging of the Chassis' droop ears. And are lightweight being Ti. And these are the best hands down, if you care about your chassis. Or running an expensive upgrade chassis. Chassis ears can get really gouged out and you end up with more droop than you had set, over time. Droop gets all jacked up, and needs constant adjusting as the chassis Alloy wears to literally nothing.

The correct way. Arrma does sell them separately . I use them. You get like 8 of them for 2 Models. But on many of my models, I also use the Avid Titanium Domed droop screws. 1/8 track crowd use these exclusively. The smooth button head (no hex) prevents gouging of the Chassis' droop ears. And are lightweight being Ti. And these are the best hands down, if you care about your chassis. Or running an expensive upgrade chassis. Chassis ears can get really gouged out and you end up with more droop than you had set, over time. Droop gets all jacked up, and needs constant adjusting as the chassis Alloy wears to literally nothing.

M2C also makes very decent M4 Droop Screws. Wider domed. FWIW.

M2C also makes very decent M4 Droop Screws. Wider domed. FWIW.

Last edited:

jkflow

TB RC Bashers

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

Yes, those droop screws are a pain but luckily you only adjust them once.

M2C and others have the ones with a top hex.

M2C and others have the ones with a top hex.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

Yeah with 1/8 bashers , our droop is usually set and forget, once we get it dialed just right, then leave it there. The track guys are constantly adjusting their chassis to differing tracks or conditions, shock Droop and all.

Grocery Ninja

Member

- Thread starter

- #29

I ordered the hot racing ones. Hopefully they fit correctly. Until they're installed I'm going to keep it on the ground. Sooo tempting to start learning how to jump. I've been watching videos and reading about technique.

KevinC

Flyboy, Cat Hoarder, Tiger Tamer, Party Crasher.

Lifetime Premium!

Premium Member

Build Thread Contributor

- Messages

- 2,346

- Reaction score

- 4,034

- Location

- Brantford,Ontario

- Arrma RC's

- Fireteam

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Mojave EXB

- Talion

- Talion EXB

Thank you so much everyone, I absolutely love all of the engagement in this forum. A little update. HH sent me a new set of cups, the front diff looked awesome and was tight as a drum. I put 50k oil back in it and it drives awesome. I ran two packs through it at a park in the freshly mowed grass and on a long dirt driveway and it's so fast and controllable. I'll probably put some heavier fluid in the rear next time I have stuff apart. I think they put the wrong droop screws in because if the rounded head is down toward the chassis there's no way to adjust them. I attached a picture. After doing some research I found some that have a hex in the other end too, so I have those on the way.

View attachment 299452

The rounded head is supposed to go toward the chassis so the installation is correct here. Adjustment on these type of screws is from the underneath (undesirable).

The screws the other guy’s mentioned above are better and can be adjusted from the top.

cheers,

kev

KevinC

Flyboy, Cat Hoarder, Tiger Tamer, Party Crasher.

Lifetime Premium!

Premium Member

Build Thread Contributor

- Messages

- 2,346

- Reaction score

- 4,034

- Location

- Brantford,Ontario

- Arrma RC's

- Fireteam

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Mojave EXB

- Talion

- Talion EXB

Ps.

adjustment from underneath is a bit easier if you have a ball head hex driver. That way, you can angle it in there.

adjustment from underneath is a bit easier if you have a ball head hex driver. That way, you can angle it in there.

- Messages

- 6,174

- Reaction score

- 9,033

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

That’s what I do as wellPs.

adjustment from underneath is a bit easier if you have a ball head hex driver. That way, you can angle it in there.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

+1The rounded head is supposed to go toward the chassis so the installation is correct here. Adjustment on these type of screws is from the underneath (undesirable).

The screws the other guy’s mentioned above are better and can be adjusted from the top.

cheers,

kev

They simply aren't Real Droop screws if they need to be adjusted from the Bottom.

The Arms need to contact and touch the button head/dome of the Screw, and adjustments need to be done from the top threaded end, having a Broached Hex on it. By adjusting from the Bottom at the screw head requires pushing the Arm away for turning it, and is NOT the correct or accurate way to do this. A ruler or Caliper (best) is always used to measure shock droop from the Shocks' top and bottom eyelets. Each shock in pairs must match in droop identically.

I usually start with max droop, then reduce it by 5mm. A good place to start for most rigs. This will protect the shocks from over extending and snapping a piston or bottom shaft End.

But proper droop does more for handling. If you don't understand it, need to read up on Shock droop more. Often overlooked with Basher type models..

Droop is considered a Shock adjustment. Many think it simply adjusts the Arms' deflection. It does, but does more than just this for the suspension and handling. Always check and adjust your Shock Preload again , after you set shock droop. And double check the whole alignment.

Last edited:

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,248

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

One thing I always thought was dumb was that you have to remove the upper a arms to properly set the droop on the front.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I recommend using Oil in the Rear diff, that is aprox half the CST of the Front diff. ( 20-30K) As a start. Then drive it and get comfortable with it. Too thick in the rear will make these Pivot Ball type platforms harder to steer. From my exper.Thank you so much everyone, I absolutely love all of the engagement in this forum. A little update. HH sent me a new set of cups, the front diff looked awesome and was tight as a drum. I put 50k oil back in it and it drives awesome. I ran two packs through it at a park in the freshly mowed grass and on a long dirt driveway and it's so fast and controllable. I'll probably put some heavier fluid in the rear next time I have stuff apart. I think they put the wrong droop screws in because if the rounded head is down toward the chassis there's no way to adjust them. I attached a picture. After doing some research I found some that have a hex in the other end too, so I have those on the way.

View attachment 299452

In the end what works for you. Just need to drive it alot to adapt to changes first before making other changes. Sometimes "good enough" presents itself

and you learn to drive it that way. Developing your own driving style. No 2 rigs are ever alike.

Radiocontrolsoul

Active Member

- Messages

- 392

- Reaction score

- 1,111

Yea, I’ve gone as far as drilling a small hole in the upper arm to get the driver straight inOne thing I always thought was dumb was that you have to remove the upper a arms to properly set the droop on the front.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,248

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

I remember years ago someone posted pics on Facebook showing that they did this to their car and so many people were yelling at home for weakening his a armsYea, I’ve gone as far as drilling a small hole in the upper arm to get the driver straight in

- Messages

- 6,174

- Reaction score

- 9,033

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

That’s what Raz doesYea, I’ve gone as far as drilling a small hole in the upper arm to get the driver straight in

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,881

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

+!One thing I always thought was dumb was that you have to remove the upper a arms to properly set the droop on the front.

That's why I drill a hole directly above the droop screw, drilling one hole on both Upper Arms to place my Hex driver through and reach a proper "Droop Screw" threaded end at the top. The best way for quick access. Try it if you haven't already. Many do this.

Adjusting droop at the bottom of the Arm is just the incorrect and ineffective way. Any pro Track guy will tell you this. Doing it right is quick and most accurate.

Sometimes simply a "Ball" hex tip driver will gain access and enough purchase to the Droops screw hexes, without any drilling of the upper arms needed. Depends on the platform and type/shape of the upper arms.

Last edited:

I take the shocks off at the top then you can get to the droop screws easerOne thing I always thought was dumb was that you have to remove the upper a arms to properly set the droop on the front.