I've been getting a lot wear in pivot pin area of a-arms which I know is normal wear and tear, arms are in great shape other than the slop at the pivots pins. This being said my thought was why not bush them SO I DID!!!

First was to order some brass tubing to do the job, found this on Amazon https://www.amazon.com/gp/product/B07Z9BHSY8/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

with o.d. of tube being 5.00mm I used drill bit size of 4.97mm for a good press fit

after this I cut tubing for width of arm to be installed in

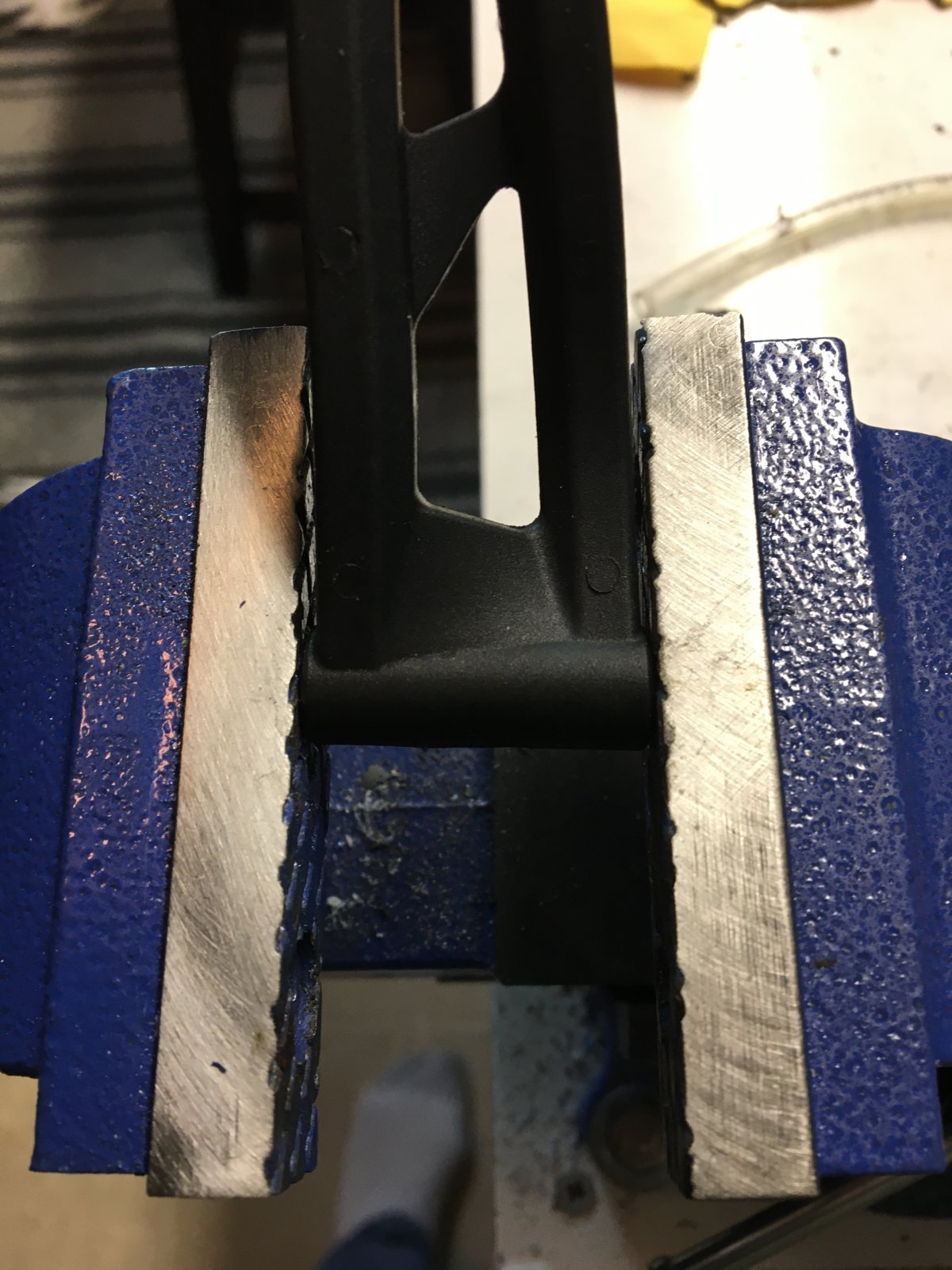

once tube is cut I used needle nose pliers to ream ends then using bench vise press tubing into arm

I'm hoping this adds a lot of new life to my a-arms, movement is super smooth and the slop is gone hope this helps some in the future. I was really happy how it worked out for me and have a great day everyone!!

First was to order some brass tubing to do the job, found this on Amazon https://www.amazon.com/gp/product/B07Z9BHSY8/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

with o.d. of tube being 5.00mm I used drill bit size of 4.97mm for a good press fit

after this I cut tubing for width of arm to be installed in

once tube is cut I used needle nose pliers to ream ends then using bench vise press tubing into arm

I'm hoping this adds a lot of new life to my a-arms, movement is super smooth and the slop is gone hope this helps some in the future. I was really happy how it worked out for me and have a great day everyone!!