Agreed. It's trial and error. I ended up using 2 of those nylon washer under each piston. 3 was too much so I used the screws to meet in the middle. It also makes it harder to put the spring perch and shock end back on.Yeah, putting spacers under the pistons works, but it definitely isn't convenient having to take out your shocks, drain them, disassemble your shocks, take spacers out, put spacers in, refill the shocks, etc. every time you want to adjust droop.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Limitless Dual Motor Limitless tp motors scorched full length chassis

- Thread starter vwturbowolf

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

Definitely. Especially if you're using ultra stiff springs. It makes it almost impossible to pop those suckers in there. Well, for me anyways. I don't have Paul Bunyan kinda strength.Agreed. It's trial and error. I ended up using 2 of those nylon washer under each piston. 3 was too much so I used the screws to meet in the middle. It also makes it harder to put the spring perch and shock end back on.

I'm using the Joe Diaz springs. I ended up using every cuss word in the book plus some made up one's. Ended up using the Hot Racing one's I had. Held the piston nut and just screwed them on. Worked great actually.Definitely. Especially if you're using ultra stiff springs. It makes it almost impossible to pop those suckers in there. Well, for me anyways. I don't have Paul Bunyan kinda strength.

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

Joe Diaz it is. It's scary how similar our cars areI'm using the Joe Diaz springs. I ended up using every cuss word in the book plus some made up one's. Ended up using the Hot Racing one's I had. Held the piston nut and just screwed them on. Worked great actually.

Bet mine's been a plane more than yours.Joe Diaz it is. It's scary how similar our cars are

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

"Just one more pass..." -- Famous last word by everyone ever, probablyBet mine's been a plane more than yours.I didn't get this Sundays crash on video. I was about to strap on the GoPro I got from @real_name_hidden but decided one more test pass.

You're probably right. I haven't had a blow over in a good long while. I know I just screwed myself by saying the quiet part out loud but, that's just how I roll...or fly. Whatever the case may be.

- Messages

- 1,601

- Reaction score

- 4,871

- Location

- Maryland

- Arrma RC's

- Infraction

- Limitless

- Mojave EXB

- Senton 3s

- Talion

- Typhon 3s

- Vendetta

- Thread starter

- #107

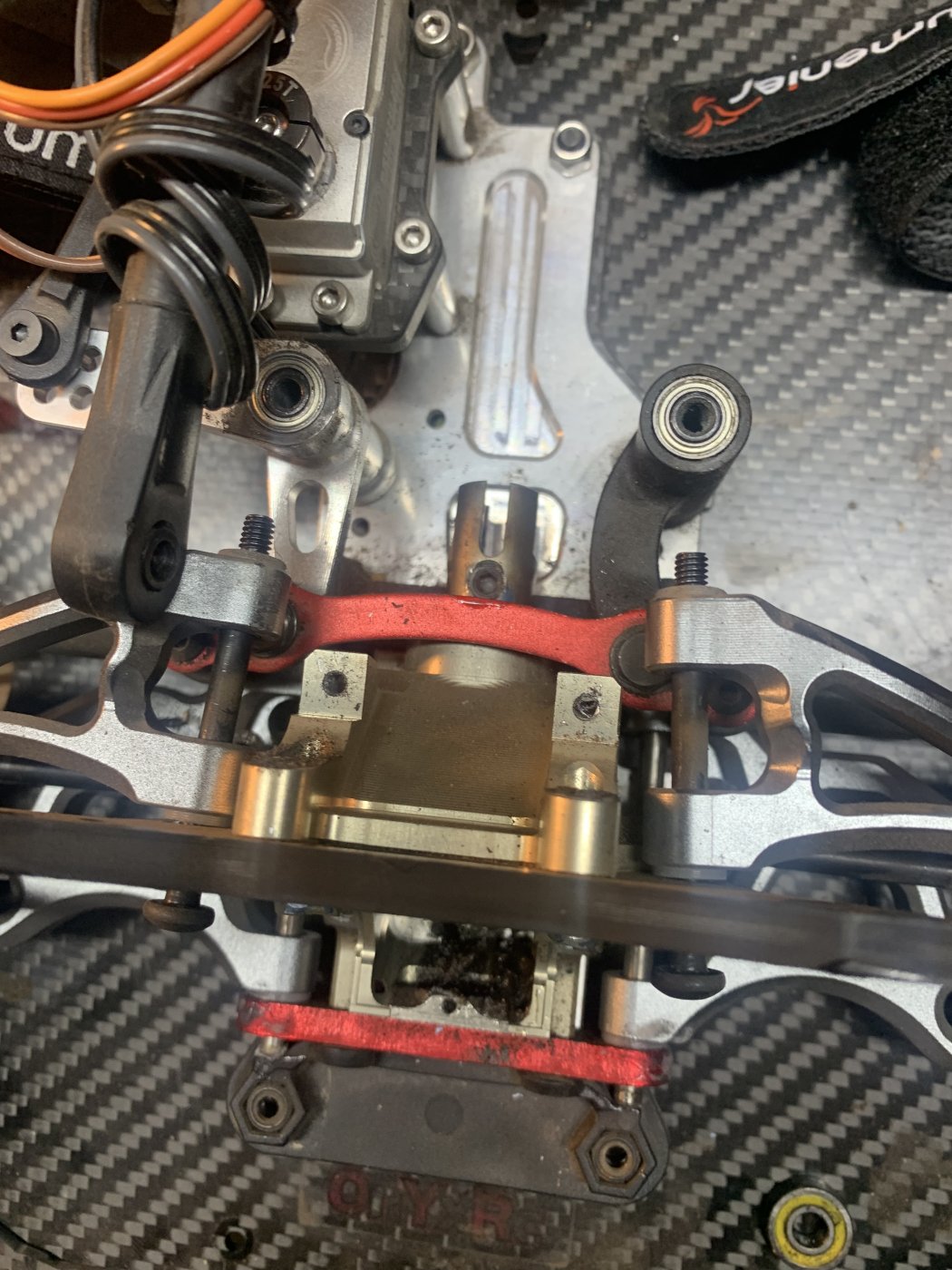

I ended up doing all three on this build for a couple reasons.

My single motor car uses front lower aluminum for the flex because it was bending the arms above 160. But I had to glue the other arms a lot to keep them from moving.

With the aluminum arms on this car I was able to shim the arms at the pins so that I know the caster of the wheels is exact and they are t glued so I can still take everything apart if needed

My single motor car uses front lower aluminum for the flex because it was bending the arms above 160. But I had to glue the other arms a lot to keep them from moving.

With the aluminum arms on this car I was able to shim the arms at the pins so that I know the caster of the wheels is exact and they are t glued so I can still take everything apart if needed

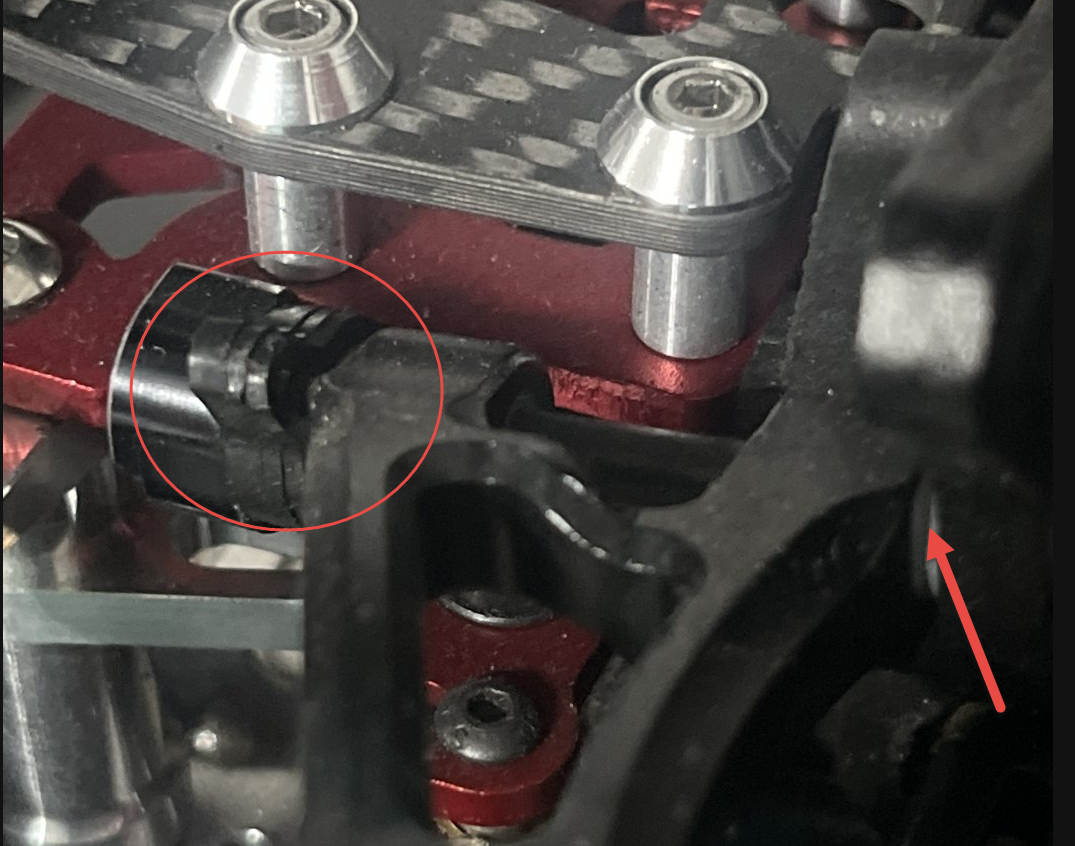

So in 1:1 cars positive caster creates high speed stability. I’ve left the stock shims where they are. If I was to move them to the front of the upper arm I should be more stable. Am I correct in thinking this translates to RC? Pic below just to be clear.I ended up doing all three on this build for a couple reasons.

My single motor car uses front lower aluminum for the flex because it was bending the arms above 160. But I had to glue the other arms a lot to keep them from moving.

With the aluminum arms on this car I was able to shim the arms at the pins so that I know the caster of the wheels is exact and they are t glued so I can still take everything apart if needed

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

You're talking about moving these shims to here?

Yea. I worked a 13 hour day so I’m not sure if I have that backwards. LolYou're talking about moving these shims to here?

View attachment 242141

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

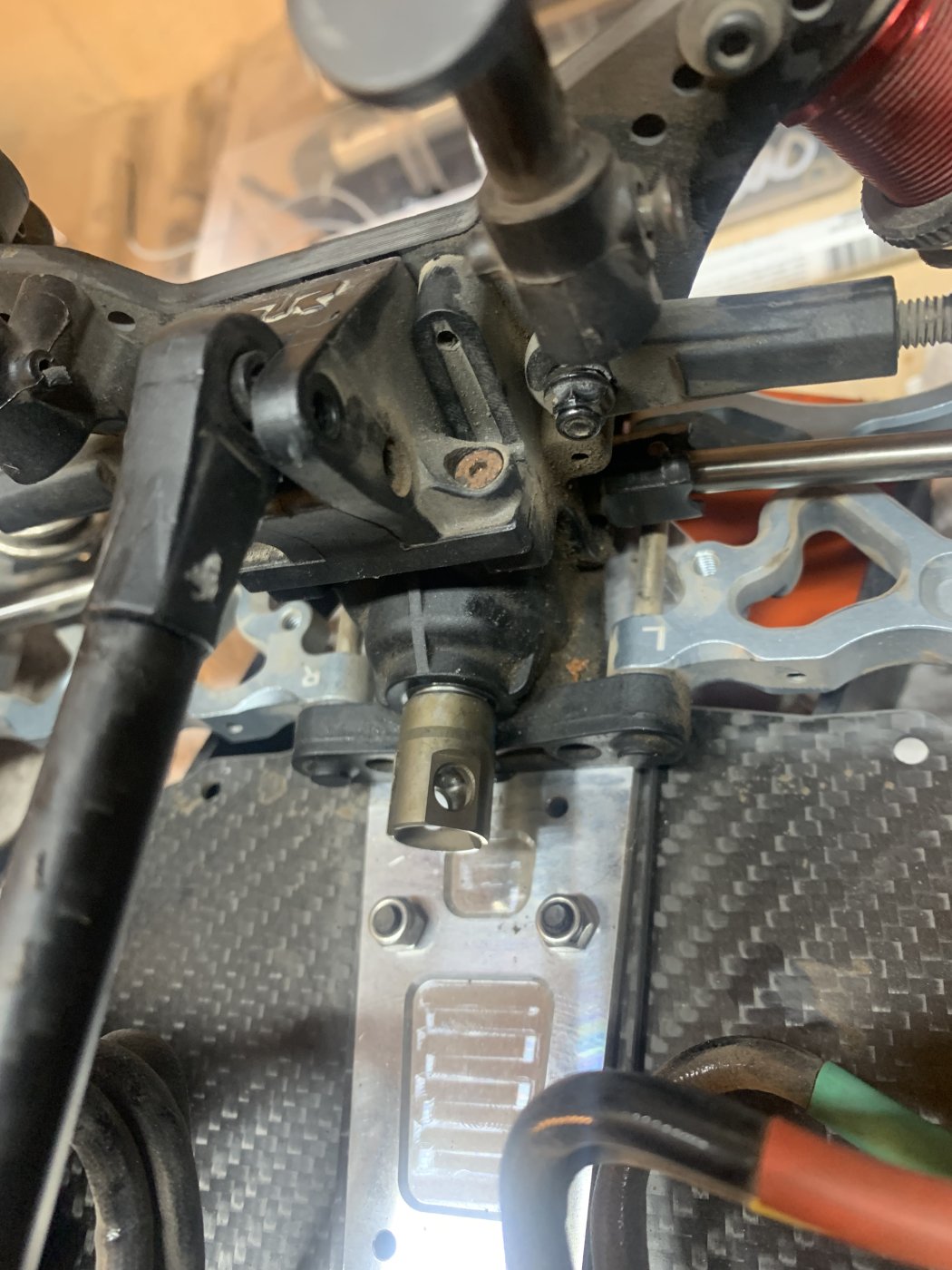

Well, yours are where they are in the stock configuration. I had never considered moving them or what effect that might have. So the idea is that moving the shims would increase caster? If so I may need to take a look at that. I just shimmed up my front bulkhead to at the back (hope that makes sense) to level out the front center drive shaft to help alleviate stress on the shaft from the downward pointed front diff input which will obviously reduce caster a little bit. If I could recoup a little bit of that by moving the shims...not a bad thought.Yea. I worked a 13 hour day so I’m not sure if I have that backwards. Lol

Exactly. Pic for reference.Well, yours are where they are in the stock configuration. I had never considered moving them or what effect that might have. So the idea is that moving the shims would increase caster? If so I may need to take a look at that. I just shimmed up my front bulkhead to at the back (hope that makes sense) to level out the front center drive shaft to help alleviate stress on the shaft from the downward pointed front diff input which will obviously reduce caster a little bit. If I could recoup a little bit of that by moving the shims...not a bad thought.

Diem Turner

Yes...I have a Premium Member

Premium Member

Excellence Award

Rig of the Month Winner

Build Thread Contributor

Top friggin' notch. Thanks broExactly. Pic for reference. View attachment 242143

- Messages

- 1,601

- Reaction score

- 4,871

- Location

- Maryland

- Arrma RC's

- Infraction

- Limitless

- Mojave EXB

- Senton 3s

- Talion

- Typhon 3s

- Vendetta

- Thread starter

- #114

Got a small update with this build. And also wanted to document my runs on one post so far to help me keep track of them

So far my runs were as follows:

1st gearing setup

1st session

4s 144mph

7s 97% throttle 176

Tires lost 2

Bearings changed

———————

2nd session

7s 187

7s 183 same charge

Tires lost 2

Bearings + new front shaft

———————

3rd session

7s 188

7s 186 same charge

Tires lost 4

Bearings changed

———————

4th session lowered gearing (-40mph geared to speed)

7s 181

Tires lost 2

Bearings changed + new front shaft

———————

5th session same gearing

8s 1st pass no gps read

8s 191 same charge

Tires lost 6

Bearings changed + new front shaft

Wanted to also note the bearings/shafts and tires lost for these passes so that everyone can see the investment made for these speeds.

With all that laid out,

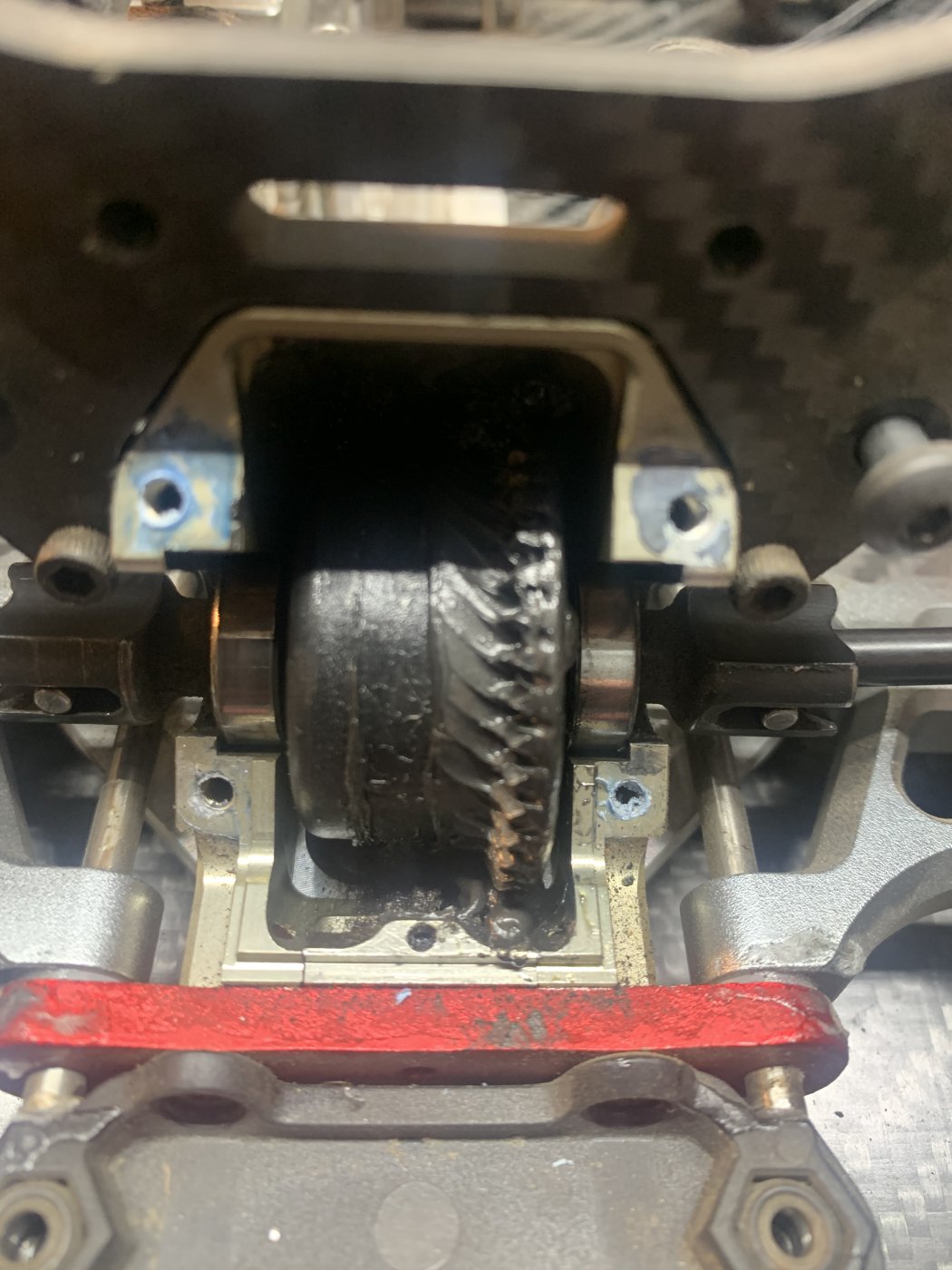

I’m starting to see a small small improvement in bearing life setting up my front and rear exactly the same with a front vitavon bulkhead and rear plastic bulkhead. Today the front bearing came out in one piece and the rear(from the plastic housing) came apart in many pieces.

It seems as long as I change them within 2-3 runs, the front aluminum bulkhead is not egging out and it staying better in tact then the smaller bearing in the rear.

Take it with a grain of salt, anything can happen but I have seen the last two bearing changes the front has come out in one piece. At speeds above 150-160 I recommend changing the bearings after every single session 1-3 passes no matter what you think they feel like. Or else the risk of complete failure is extremely high

So far my runs were as follows:

1st gearing setup

1st session

4s 144mph

7s 97% throttle 176

Tires lost 2

Bearings changed

———————

2nd session

7s 187

7s 183 same charge

Tires lost 2

Bearings + new front shaft

———————

3rd session

7s 188

7s 186 same charge

Tires lost 4

Bearings changed

———————

4th session lowered gearing (-40mph geared to speed)

7s 181

Tires lost 2

Bearings changed + new front shaft

———————

5th session same gearing

8s 1st pass no gps read

8s 191 same charge

Tires lost 6

Bearings changed + new front shaft

Wanted to also note the bearings/shafts and tires lost for these passes so that everyone can see the investment made for these speeds.

With all that laid out,

I’m starting to see a small small improvement in bearing life setting up my front and rear exactly the same with a front vitavon bulkhead and rear plastic bulkhead. Today the front bearing came out in one piece and the rear(from the plastic housing) came apart in many pieces.

It seems as long as I change them within 2-3 runs, the front aluminum bulkhead is not egging out and it staying better in tact then the smaller bearing in the rear.

Take it with a grain of salt, anything can happen but I have seen the last two bearing changes the front has come out in one piece. At speeds above 150-160 I recommend changing the bearings after every single session 1-3 passes no matter what you think they feel like. Or else the risk of complete failure is extremely high

So the only bearings you change consistently are the input cup bearings?Got a small update with this build. And also wanted to document my runs on one post so far to help me keep track of them

So far my runs were as follows:

1st gearing setup

1st session

4s 144mph

7s 97% throttle 176

Tires lost 2

Bearings changed

———————

2nd session

7s 187

7s 183 same charge

Tires lost 2

Bearings + new front shaft

———————

3rd session

7s 188

7s 186 same charge

Tires lost 4

Bearings changed

———————

4th session lowered gearing (-40mph geared to speed)

7s 181

Tires lost 2

Bearings changed + new front shaft

———————

5th session same gearing

8s 1st pass no gps read

8s 191 same charge

Tires lost 6

Bearings changed + new front shaft

Wanted to also note the bearings/shafts and tires lost for these passes so that everyone can see the investment made for these speeds.

With all that laid out,

I’m starting to see a small small improvement in bearing life setting up my front and rear exactly the same with a front vitavon bulkhead and rear plastic bulkhead. Today the front bearing came out in one piece and the rear(from the plastic housing) came apart in many pieces.

It seems as long as I change them within 2-3 runs, the front aluminum bulkhead is not egging out and it staying better in tact then the smaller bearing in the rear.

Take it with a grain of salt, anything can happen but I have seen the last two bearing changes the front has come out in one piece. At speeds above 150-160 I recommend changing the bearings after every single session 1-3 passes no matter what you think they feel like. Or else the risk of complete failure is extremely high

View attachment 242986

View attachment 242987

View attachment 242988

View attachment 242989

- Messages

- 1,601

- Reaction score

- 4,871

- Location

- Maryland

- Arrma RC's

- Infraction

- Limitless

- Mojave EXB

- Senton 3s

- Talion

- Typhon 3s

- Vendetta

- Thread starter

- #116

Since starting to run this build when everything was newSo the only bearings you change consistently are the input cup bearings?

Outer hub bearings 1 time so far

Spool bearings 2 times so far

Diff bearings 1 time so far

Yea same here. Just not as frequent as you at this point. I’m ready to go again but after going over the car last night I guess the right rear hub got wonky after the crash and the outer race of the inner bearing wobbles inside the hub. Ordered replacements from JRC.Outer hub bearings

Spool bearings

Dan B.

Area man

Lifetime Premium!

Premium Member

ArrmaForum Fan

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,708

- Reaction score

- 18,323

- Location

- Southern Vermont

- Arrma RC's

- Fireteam

- Granite

- Limitless

- Mojave EXB

- Notorious

- Outcast 6s

- Typhon 6s

Y’all are inspiring…l

sert rc

Active Member

- Messages

- 87

- Reaction score

- 140

- Arrma RC's

- Limitless

- Kraton EXB

- Vorteks

@vwturbowolf

Thanks for posting your bearing maintenance schedule - very eye opening. Do you run ceramic bearings?

Also, how are those aluminum suspension arms holding up to high speed crashes?

Thanks for posting your bearing maintenance schedule - very eye opening. Do you run ceramic bearings?

Also, how are those aluminum suspension arms holding up to high speed crashes?

- Messages

- 1,601

- Reaction score

- 4,871

- Location

- Maryland

- Arrma RC's

- Infraction

- Limitless

- Mojave EXB

- Senton 3s

- Talion

- Typhon 3s

- Vendetta

- Thread starter

- #120

I run avid revolution aura bearings, they aren’t ceramic but seem to hold up best of the ones I’ve tried for the price. 2.50$ per bearing I don’t mind changing them often.@vwturbowolf

Thanks for posting your bearing maintenance schedule - very eye opening. Do you run ceramic bearings?

Also, how are those aluminum suspension arms holding up to high speed crashes?

The arms are good and everything has stayed very straight. Haven’t crashed this build and hope I don’t

Similar threads

- Replies

- 13

- Views

- 287