Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kraton HELP - Steering question

- Thread starter Bread1267

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

It looks like that's due to your servo saver. I'd follow @East tactics video on shimming the spring and/or adding the exb spring.

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

Like some others have said, put in some c clips or get the servo spring (which seems to be out of stock most places) and get those bushings out of there if that doesn’t completely solve it. Good luck!Yes

Looks good I just ordered this: Hot Racing Aluminum Fixed Link Steering with 25t Servo Arm, HRAAON48SH25 https://www.amazon.com/dp/B072YJ6L4C/ref=cm_sw_r_cp_api_glt_fabc_5QXRJWVJT7WKJBT10VBR

Hopefully this will fix my problems because stock servo was fine up until it died after about 2 days of running it. The servo horn that came with my new servo doesn’t allow me to mount it underneath.

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #23

Why don't you think it will help fix it? If you look at the picture you sent the steering link is under the servo arm which is directly straight connected to the steering rack. My setup has only gotten worse since I rose it up and put those washers in there. I am honestly 95% sure that my servo link being so high up is causing all of the problems. Like I said before my old stock servo worked fine and had a bunch of torque before it died and the servo link was UNDER the servo arm. I will update the thread once my servo arm and link come in the mail.So at this point I don't see the hot racing arm link helping your situation. Also definitely send HH an email. Include that video, this thread link, name, receipt etc.

Also check all the steering rack screws etc.

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

So I’m assuming that short video you posted is your rig. In that video the servo horn is moving appropriately but the tires barely move. Now focus on the servo saver. Each time you try to turn the servo does it’s job, but the upper and lower halves of the servo saver rotate/separate. That is definitively the servo saver spring. The new servo is overpowering it. The geometry of the servo arm will be more efficient if it is parallel but it is not the main cause of your problem. Finally, why did you replace the servo? Did it fail?

- Messages

- 833

- Reaction score

- 939

- Location

- Central valley California

- Arrma RC's

- Kraton 6s

- Kraton EXB

- Typhon 3s

- Typhon 6s

- Voltage

I'm definitely agree about replacing the servo horn. I didn't realize that it was on top not below. I would say keeping it the stock direction is best and my point was the whole link setup from HR is unnecessary but now I'm guessing it makes sense as it includes the servo horn.

Also my servo is in a JBIRC extended servo mount with a aluminum and plastic spacer. Its definitely raised up a bit without issues.

Here is my V5 typhon. I put my protek 370tbl servo with the exb mount and used 1 plastic washer.

Also my servo is in a JBIRC extended servo mount with a aluminum and plastic spacer. Its definitely raised up a bit without issues.

Here is my V5 typhon. I put my protek 370tbl servo with the exb mount and used 1 plastic washer.

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #26

Yes the original one failed and HH is sending me out a new one but im just gonna keep it as a backup. I got this one: https://www.amazon.com/gp/product/B07S9XZYN2/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1So I’m assuming that short video you posted is your rig. In that video the servo horn is moving appropriately but the tires barely move. Now focus on the servo saver. Each time you try to turn the servo does it’s job, but the upper and lower halves of the servo saver rotate/separate. That is definitively the servo saver spring. The new servo is overpowering it. The geometry of the servo arm will be more efficient if it is parallel but it is not the main cause of your problem. Finally, why did you replace the servo? Did it fail?

Do you suggest I still go ahead and get a stiffer spring aswell? I bought C clips and have them on standby. Also how would I even replace the spring when the servo saver is locked down with loctite?

- Messages

- 833

- Reaction score

- 939

- Location

- Central valley California

- Arrma RC's

- Kraton 6s

- Kraton EXB

- Typhon 3s

- Typhon 6s

- Voltage

He mentioned that it failed at some point. I 100% agree looking at the video. The horn and arm move but the servo saver fails somehow. He needs to contact HH or get the exb spring.So I’m assuming that short video you posted is your rig. In that video the servo horn is moving appropriately but the tires barely move. Now focus on the servo saver. Each time you try to turn the servo does it’s job, but the upper and lower halves of the servo saver rotate/separate. That is definitively the servo saver spring. The new servo is overpowering it. The geometry of the servo arm will be more efficient if it is parallel but it is not the main cause of your problem. Finally, why did you replace the servo? Did it fail?

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #28

It would have been so much easier if HH just made the spektrum servos be 25t then I could just use the stock servo horn on my new servo instead of buying a new one.I'm definitely agree about replacing the servo horn. I didn't realize that it was on top not below. I would say keeping it the stock direction is best and my point was the whole link setup from HR is unnecessary but now I'm guessing it makes sense as it includes the servo horn.

Also my servo is in a JBIRC extended servo mount with a aluminum and plastic spacer. Its definitely raised up a bit without issues.

Here is my V5 typhon. I put my protek 370tbl servo with the exb mount and used 1 plastic washer.

View attachment 123354

View attachment 123355

Do you think something is wrong with my servo saver and that I should try to get a new one? Or just get a stiffer spring from HH?He mentioned that it failed at some point. I 100% agree looking at the video. The horn and arm move but the servo saver fails somehow. He needs to contact HH or get the exb spring.

Last edited:

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

So odds are the servo was crap but it could have been overworked fighting the bushings and servo saver that helped shorten it’s life. I would 100% change that spring or put the clips in. If you remove the post and hit the end of the aluminum with a heat gun it will come apart.Yes the original one failed and HH is sending me out a new one but im just gonna keep it as a backup. I got this one: https://www.amazon.com/gp/product/B07S9XZYN2/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

Do you suggest I still go ahead and get a stiffer spring aswell? I bought C clips and have them on standby. Also how would I even replace the spring when the servo saver is locked down with loctite?

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #30

Alright well I am gonna add some c clips to it and then put that servo arm+ plus linkage in and ill update this thread.So odds are the servo was crap but it could have been overworked fighting the bushings and servo saver that helped shorten it’s life. I would 100% change that spring or put the clips in. If you remove the post and hit the end of the aluminum with a heat gun it will come apart.

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

Awesome, look forward to seeing the results. Good luck!Alright well I am gonna add some c clips to it and then put that servo arm+ plus linkage in and ill update this thread.

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,660

- Reaction score

- 4,518

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

Hey, not hijacking the thread but im so confused by all this that I don't know where I'm confused, lol.

I have the the same servo the OP is getting. Im doing a rebuild of my Senton 6s. ENTIRE steering assembly will be Hot Racing. I was going to use the original servo saver, but now im wondering, because of that video, if its going to be underpowered. My situation is the same. I run 2.8 MT belted Trenchers. And use the BLX 185. So, according to the video, I need a glitch buster or bec booster or change up the servo saver. Following?

My issue is, I choose this servo because its what I bought and put in my 3s. And the 3s ran on 2.8 belted Trenchers too.

So if the 6s will be underpowered, the 3s should be WAAAY underpowered on the BLX100, right? Except I found it OVERPOWERED to the point that I turned steering speed down to 42% via my transmitter. What am I missing here? Talk to me like I'm stupid, no hurt feelings because I might actually learn something.

HR knuckles will be in on Monday/Tuesday.

Here's the specs for the servo:

I have the the same servo the OP is getting. Im doing a rebuild of my Senton 6s. ENTIRE steering assembly will be Hot Racing. I was going to use the original servo saver, but now im wondering, because of that video, if its going to be underpowered. My situation is the same. I run 2.8 MT belted Trenchers. And use the BLX 185. So, according to the video, I need a glitch buster or bec booster or change up the servo saver. Following?

My issue is, I choose this servo because its what I bought and put in my 3s. And the 3s ran on 2.8 belted Trenchers too.

So if the 6s will be underpowered, the 3s should be WAAAY underpowered on the BLX100, right? Except I found it OVERPOWERED to the point that I turned steering speed down to 42% via my transmitter. What am I missing here? Talk to me like I'm stupid, no hurt feelings because I might actually learn something.

HR knuckles will be in on Monday/Tuesday.

Here's the specs for the servo:

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

Both of those ESC provide 6v to the servo. The torque of the servo will then the same regardless. A 35kg servo is plenty of power. If the wheels still aren’t turning well you need to modify the servo saver and look for binding in the system. If the servo horn and linkage is turning but your wheels aren’t check your linkages and check the servo saver.Hey, not hijacking the thread but im so confused by all this that I don't know where I'm confused, lol.

I have the the same servo the OP is getting. Im doing a rebuild of my Senton 6s. ENTIRE steering assembly will be Hot Racing. I was going to use the original servo saver, but now im wondering, because of that video, if its going to be underpowered. My situation is the same. I run 2.8 MT belted Trenchers. And use the BLX 185. So, according to the video, I need a glitch buster or bec booster or change up the servo saver. Following?

My issue is, I choose this servo because its what I bought and put in my 3s. And the 3s ran on 2.8 belted Trenchers too.

So if the 6s will be underpowered, the 3s should be WAAAY underpowered on the BLX100, right? Except I found it OVERPOWERED to the point that I turned steering speed down to 42% via my transmitter. What am I missing here? Talk to me like I'm stupid, no hurt feelings because I might actually learn something.

HR knuckles will be in on Monday/Tuesday.View attachment 123389

Here's the specs for the servo:View attachment 123390

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,660

- Reaction score

- 4,518

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

Will do. No problems yet as the Senton 6s build is waiting on the rest of the parts. The Scorched shipment will likely be the last one in. Expected to fly across the pond soon and then Customs needs to figure out how to get maximum milking, err..duty and taxes outta me.Both of those ESC provide 6v to the servo. The torque of the servo will then the same regardless. A 35kg servo is plenty of power. If the wheels still aren’t turning well you need to modify the servo saver and look for binding in the system. If the servo horn and linkage is turning but your wheels aren’t check your linkages and check the servo saver.

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #35

After installing the new servo horn and linkage the torque seems to way better than what it was at previously. Regardless, I am still not satisfied completely so I am gonna install some C clips to tighten up the spring and go from there.Awesome, look forward to seeing the results. Good luck!

watched the video and skipped posts, not sure if someone already covered this but its yours servo saver - its loose.

https://www.ebay.com/itm/Hot-Racing-AON48A02-Servo-Saver-Tube-with-Clamping-Nut-Set-AR340122/233380348097?ssPageName=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

https://www.ebay.com/itm/ARRMA-ARA3...m-X-Hard-Felony-Kraton-Limitless/193755006088

You don't necessarily need the above items but they help in the long run. For now add some washers/spacers and loctite the heck out of the nut.

https://www.ebay.com/itm/Hot-Racing-AON48A02-Servo-Saver-Tube-with-Clamping-Nut-Set-AR340122/233380348097?ssPageName=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

https://www.ebay.com/itm/ARRMA-ARA3...m-X-Hard-Felony-Kraton-Limitless/193755006088

You don't necessarily need the above items but they help in the long run. For now add some washers/spacers and loctite the heck out of the nut.

- Messages

- 78

- Reaction score

- 114

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Notorious

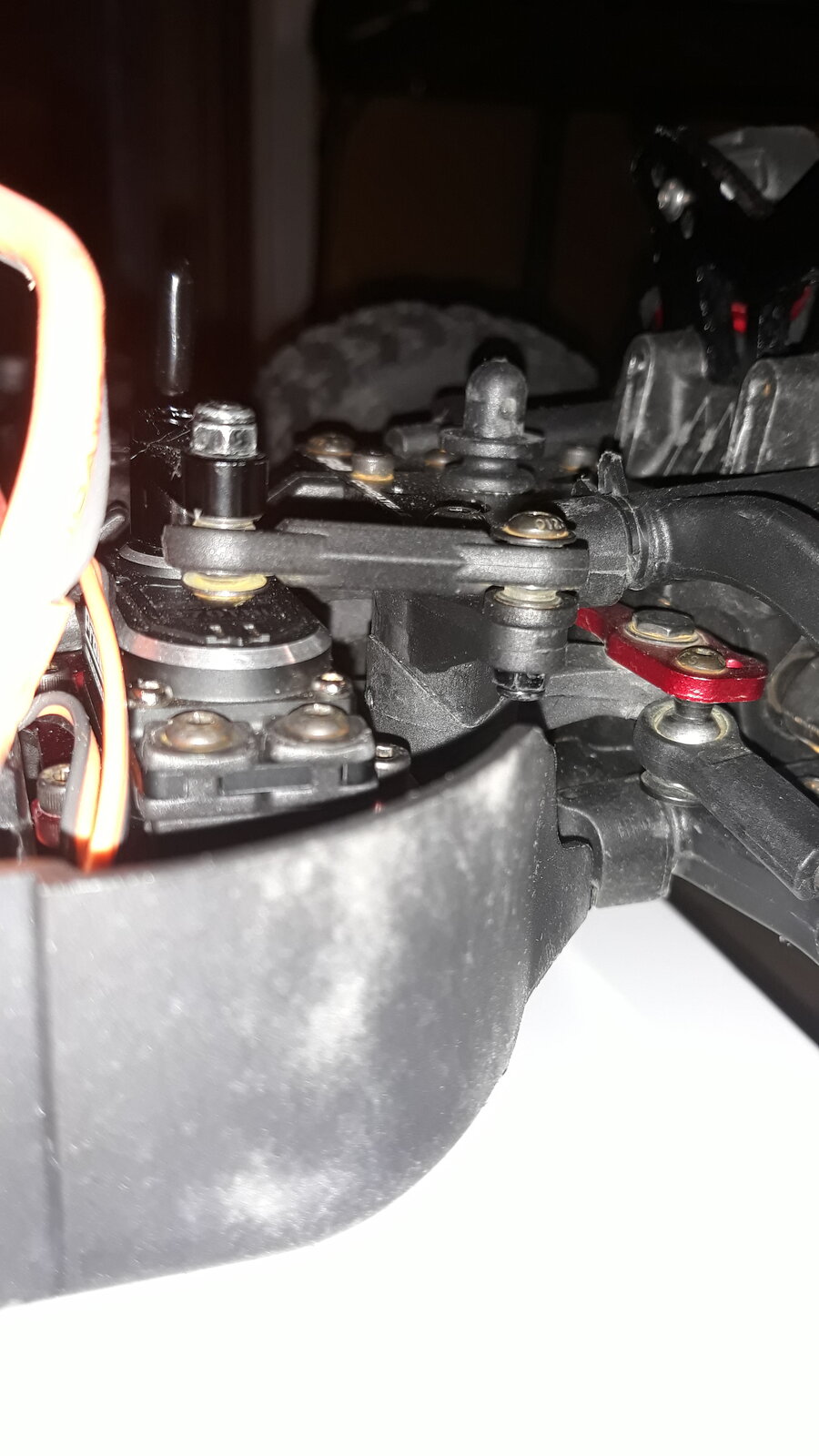

Geometry looks dead on. If you’re going to take apart the steering rack get rid of the bushings while you are in there.After installing the new servo horn and linkage the torque seems to way better than what it was at previously. Regardless, I am still not satisfied completely so I am gonna install some C clips to tighten up the spring and go from there.

View attachment 124611

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #38

You recommend some bearings or just take the bushings out in general? I added some restraining clips and it sure did tighten the spring up. Im not sure why they even made the spring for the servo saver so weak.Geometry looks dead on. If you’re going to take apart the steering rack get rid of the bushings while you are in there.

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,660

- Reaction score

- 4,518

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

Bearings. I put the HR steering links in my 3s. Didnt get rid of a hell lot of play but the bearings were a great upgrade that improved the heck out of steering control.You recommend some bearings or just take the bushings out in general? I added some restraining clips and it sure did tighten the spring up. Im not sure why they even made the spring for the servo saver so weak.

Last edited:

Bread1267

Fairly New Member

- Messages

- 25

- Reaction score

- 12

- Thread starter

- #40

What you think about this: https://www.ebay.com/itm/Hot-Racing...4630b136edf5f22e572d|ampid:PL_CLK|clp:2334524Bearings. I put the HR steering links in my 3s. Didnt get rid of a hell pot of play but the bearings were a great upgrade that improved the heck out of steering control.