Nice straight cuts! Looks great!Transferred to tape on top of the carbon fiber.

View attachment 75165

Cut with my jigsaw and Bosch carbon fiber cutting blade.

View attachment 75166

Very happy with the results!

I can't wait to get the body started, but first I need to machine some bearing carriers for the shafts.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typhon LibertyMKiii's Typhon GT streamliner and 4Tec 2.0 speed run projects

- Thread starter LibertyMKiii

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #142

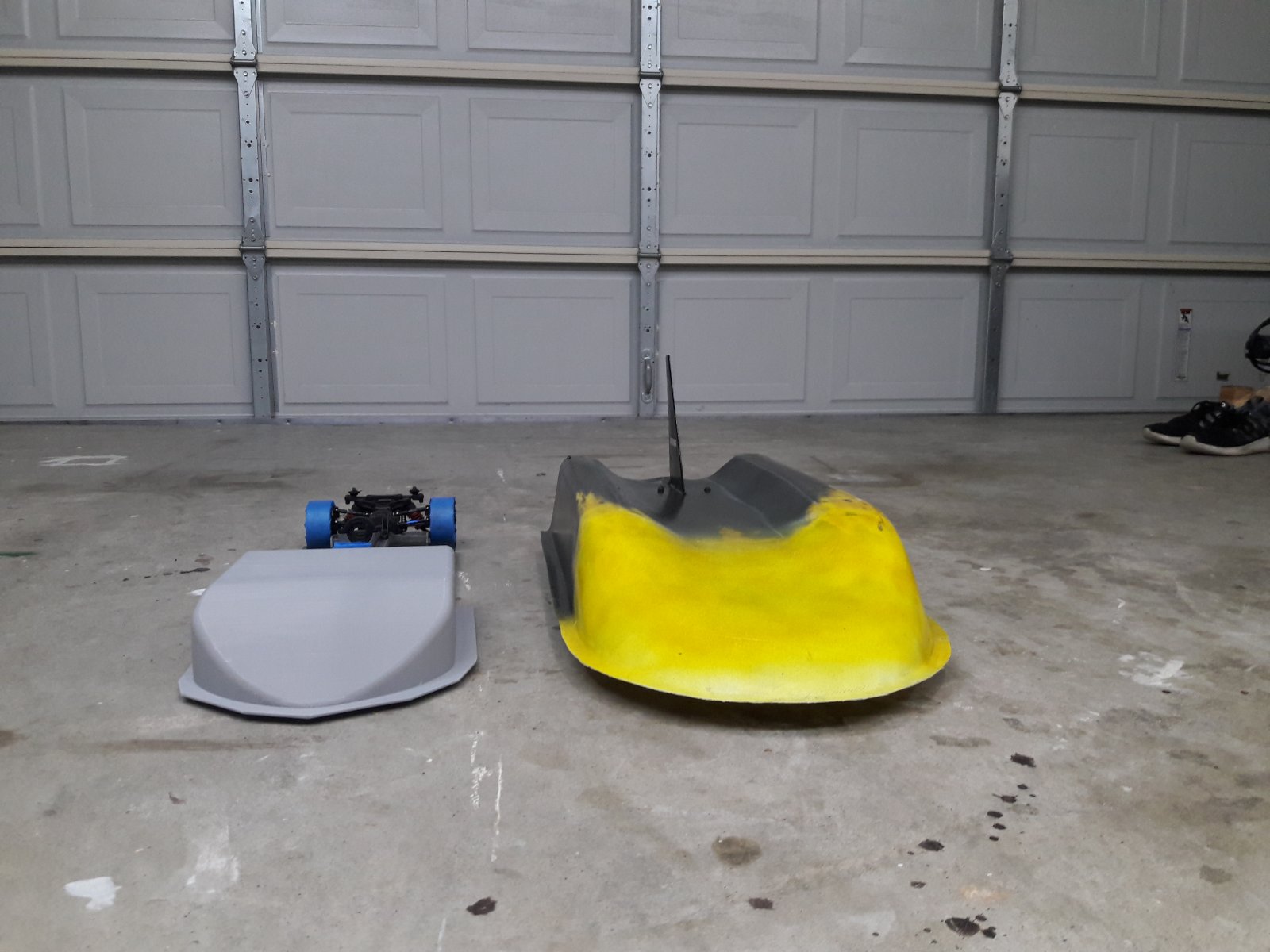

Beginnings of the 4tec stretch body mold/plug.

Easy to see why this can be significantly more aerodynamic

Easy to see why this can be significantly more aerodynamic

Beginnings of the 4tec stretch body mold/plug.

Easy to see why this can be significantly more aerodynamic

View attachment 75967

View attachment 75968

Much less frontal area.....

Very cool! 3d printed front?

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #145

Just going to be used to create a mold as the filament isn't stiff enough for 140+ mph uses.Very cool! 3d printed front?

I'll make a body out of fiberglass or carbon fiber like I did on the Unlimited project.

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,840

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

I will take the first reject ?????

How’s the chassis going so far? Are you replacing the stock chassis with just CF or doing a combination of the two?

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #148

Chassis is basically done with the exception of setting up the bearing carriers and center brace. I'll also have to do some cuts for the battery straps. Due to the design on this chassis I had to do a combination of the two parts. Saga Custom RC has a design where he replaces the center chassis, but I know some people who have that chassis and noticed that it eats up 3mm of the already minimal ground clearance. This design sits on top of the chassis so there is no loss of ground clearanceHow’s the chassis going so far? Are you replacing the stock chassis with just CF or doing a combination of the two?

I am going to do some triangulation from the center brace to the upper camber arm. GPM makes a part for this which I used on my previous 4tec but want to make something custom (shocking I know) That is why the upper brace cardboard template has "wings".

Last edited:

Very cool!!

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #150

Picked up a tool for helping with gearing choices. The SkyRC Brushless motor analyzer. I hate to have yet another tool that gets used 1 time a year, but I am all about data, and informed decisions.

You could have several BLX 2050 KV motors tested and each would come out as a different actual KV.

Mine is certainly under the rated KV. Tests range between 1905 and 1918 KV.

I don't know the full history of the motor as I bought the Typhon used, but I opened it up, changed the bearings, and all looked great.

We are finally settled into the new home and all of my wife's curtains are hung

Now just waiting for a good weather day to prove this Typhon runs 130+ on the factory motor! (I think it has 140+ in it after a gear change)

You could have several BLX 2050 KV motors tested and each would come out as a different actual KV.

Mine is certainly under the rated KV. Tests range between 1905 and 1918 KV.

I don't know the full history of the motor as I bought the Typhon used, but I opened it up, changed the bearings, and all looked great.

We are finally settled into the new home and all of my wife's curtains are hung

Now just waiting for a good weather day to prove this Typhon runs 130+ on the factory motor! (I think it has 140+ in it after a gear change)

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #151

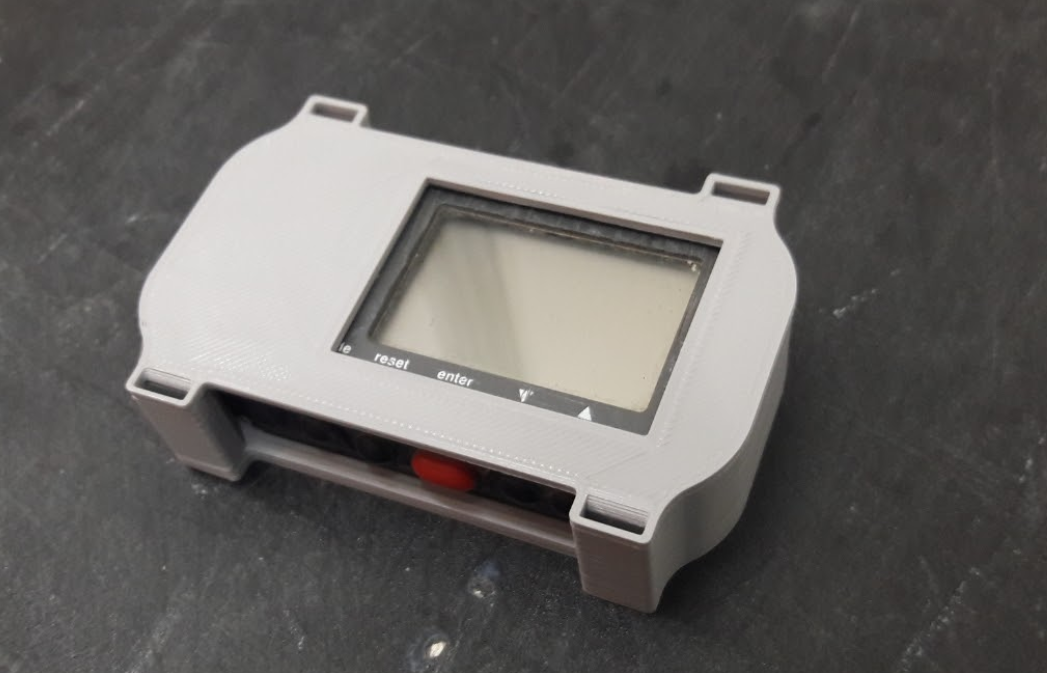

I am looking to relocate my GPS either hanging on the rear diff outside the body or on the front diff in the front bumper area. This way it will be visible without having to pull the body off.

As some insurance to these highly volnerable locations I figured it needs a case. Garmin Forerunner 301s are getting harder to find these days.... This likely won't be the final design, but V1 looks fairly decent.

As some insurance to these highly volnerable locations I figured it needs a case. Garmin Forerunner 301s are getting harder to find these days.... This likely won't be the final design, but V1 looks fairly decent.

- Messages

- 556

- Reaction score

- 833

- Arrma RC's

I just got one of these, but have not tried it yet. Looks promising. Picks up sats pretty quick, links to phone via blu tooth. Supposedly, when it looses blu tooth connection with your phone, the unit keeps on recording, and re-connects to the phone, when back in range. Rechargeable battery. We'll see. https://usa.banggood.com/SKYRC-GSM0...ICh2E7Q6WEAQYCiABEgJYNPD_BwE&cur_warehouse=CN

I am looking to relocate my GPS either hanging on the rear diff outside the body or on the front diff in the front bumper area. This way it will be visible without having to pull the body off.

As some insurance to these highly volnerable locations I figured it needs a case. Garmin Forerunner 301s are getting harder to find these days.... This likely won't be the final design, but V1 looks fairly decent.

View attachment 79400

View attachment 79401

DAY-UM....that's pretty nice!

I keep seeing more and more reasons to get a printer. With all the stuff I'm selling on eBay, and the space it's freeing up downstairs, I can almost see one in the future.....

very cool @LibertyMKiii

I ordered a 3d printer but it’ll be weeks before I get it. Fortunately, this gives me time to learn fusion 360 which I’m learning fairly easily atm.

DAY-UM....that's pretty nice!

I keep seeing more and more reasons to get a printer. With all the stuff I'm selling on eBay, and the space it's freeing up downstairs, I can almost see one in the future.....

I ordered a 3d printer but it’ll be weeks before I get it. Fortunately, this gives me time to learn fusion 360 which I’m learning fairly easily atm.

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #155

Revised the design to use zip ties and might sell a few.

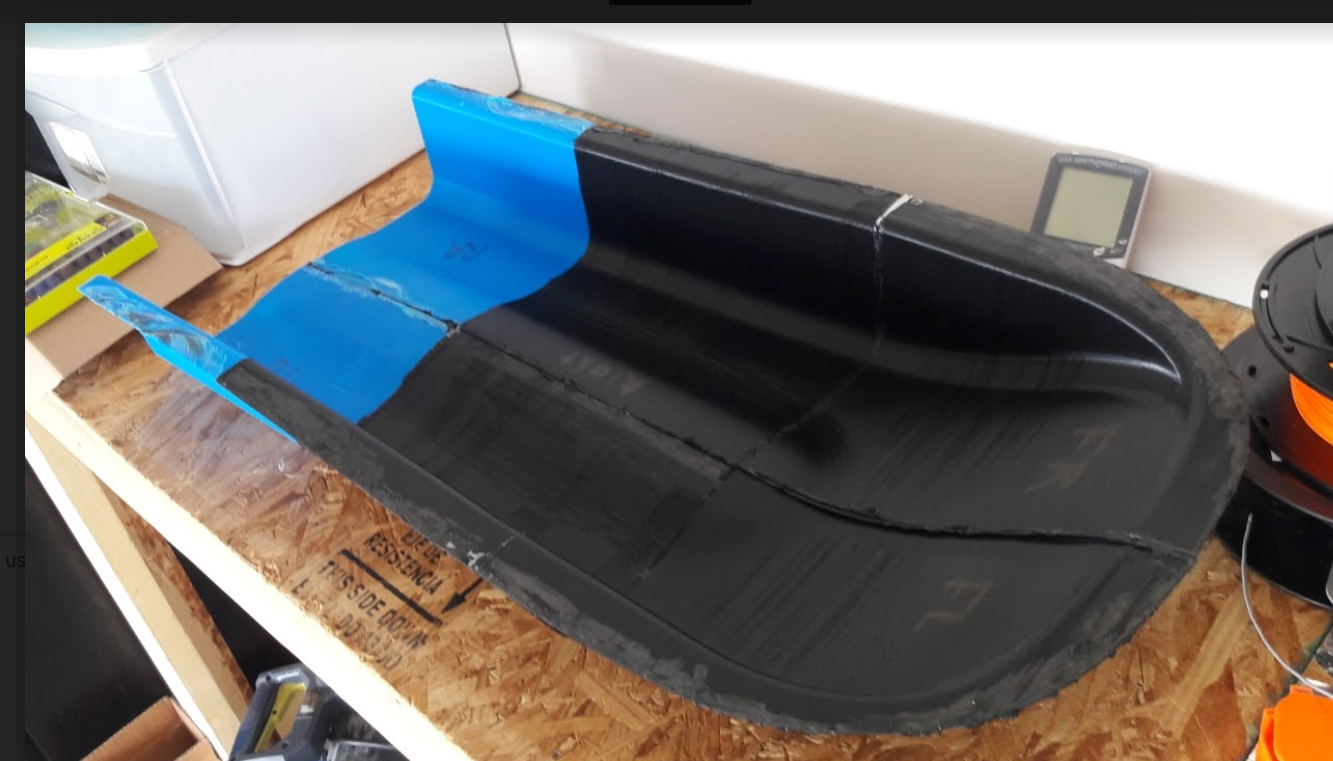

Printed the last 2 pieces of the 1/8 and 1/7 bodies and used some BSI CA glue to connect the pieces.

I have TOOOONNNNNSSSSSS of sanding and prep work ahead of me. My least favorite part of the process

In a worst case scenario I have a boat

Printed the last 2 pieces of the 1/8 and 1/7 bodies and used some BSI CA glue to connect the pieces.

I have TOOOONNNNNSSSSSS of sanding and prep work ahead of me. My least favorite part of the process

In a worst case scenario I have a boat

Your design is awesome for the gps! Good luck on the sanding! I think I’d rather do that then paint another body lol!

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #157

Boca ceramic bearings and 11 mm bit for the mill finally came in for the 4tec 2.0 project.

This aluminum bar stock is overkill for this scale, but I got a good price on it.

This was one of my largest concerns and glad to have this step done!

Lots of aluminum all over to clean up with the shop vac tomorrow after the kids wake up

This aluminum bar stock is overkill for this scale, but I got a good price on it.

This was one of my largest concerns and glad to have this step done!

Lots of aluminum all over to clean up with the shop vac tomorrow after the kids wake up

Nicely done!!

jondilly1974

Speed running apprentice, motor Slayer 🤘

Lifetime Premium!

Premium Member

Excellence Award

Build Thread Contributor

- Messages

- 26,134

- Reaction score

- 38,840

- Location

- Toledo, OH

- Arrma RC's

- Granite

- Infraction

- Kraton 6s

- Kraton EXB

- Senton 3s

- Typhon 6s

- Typhon 3s

I see you went with the blue drift tire tape. Kev used green ??????Boca ceramic bearings and 11 mm bit for the mill finally came in for the 4tec 2.0 project.

This aluminum bar stock is overkill for this scale, but I got a good price on it.

View attachment 80554

View attachment 80555

This was one of my largest concerns and glad to have this step done!

Lots of aluminum all over to clean up with the shop vac tomorrow after the kids wake up

- Messages

- 10,106

- Reaction score

- 24,877

- Location

- TENNESSEEESSEEEEEE

- Arrma RC's

- Limitless

- Mojave

- Typhon 6s

- Thread starter

- #160

The shaft coupler I got is steel and is quite heavy. I noticed it's considerably thicker than it needs to be with 10mm walls.

Emco Unimat SL to the rescue again...

It could use a little polish and finishing, but I'm exhaust for the day. It now has 5mm walls. Weight reduced by 1/2 and will be plenty strong still!

Emco Unimat SL to the rescue again...

It could use a little polish and finishing, but I'm exhaust for the day. It now has 5mm walls. Weight reduced by 1/2 and will be plenty strong still!

Last edited: