- Messages

- 1,802

- Reaction score

- 3,286

- Location

- Tennessee

- Arrma RC's

- Felony

- Infraction

- Limitless

- Kraton EXB

- Mojave

- Outcast EXB

- Senton 6s

- Vendetta

I figured I'd start my own thread of good and bad experiences in the 3d printing game. Some things I want to post just don't fit on other threads and I don't want to keep starting multiple threads. This will only be for my highlights. Major achievements and major failures, nothing in between.

I wont go backwards only forwards. I have done a lot throughout the years of printing but who cares.... right... On with the thread...

So i've only tried TPU a couple times, always with failure @Dutch helped me understand what google literally would not tell me at all. It's 100% about speed. I'd like to elaborate my findings on that. With that knowledge I had a successful print, got cocky and ramped speed up to high and got failures.

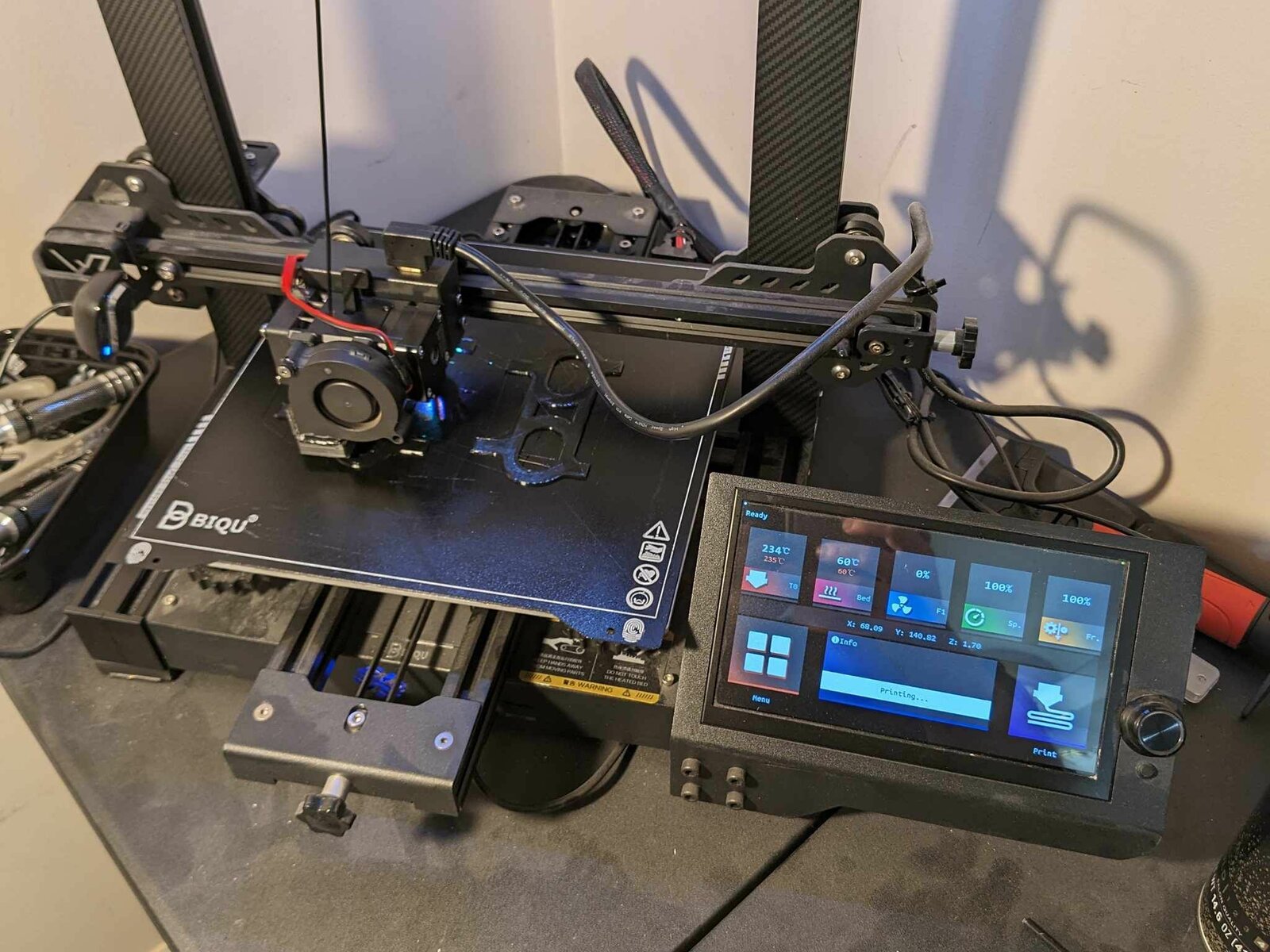

A few hours ago I set everything on my BIQU BX back to 20mm/s, upped the heat to the hot-end some, and tried TPU again. My N4M is busy and cant be bothered lol....

So far so good. And for me the issue with printing at a faster speed is with extrusion. The filament is so flimsy that if I extrude to fast my "pullies with teeth" (i'm sure they have a name) that grab the filament strip the filament and then just cause it to jam and wad up above the hotend. I'm assuming this is everyone's issue with fast extrusion of TPU but I have only really successfully done this on 1 printer that it seems no body but me has, aside from a ton of people that upgrade their ender's with bigtree tech boards and extruders so they are basically BIQU's .

.

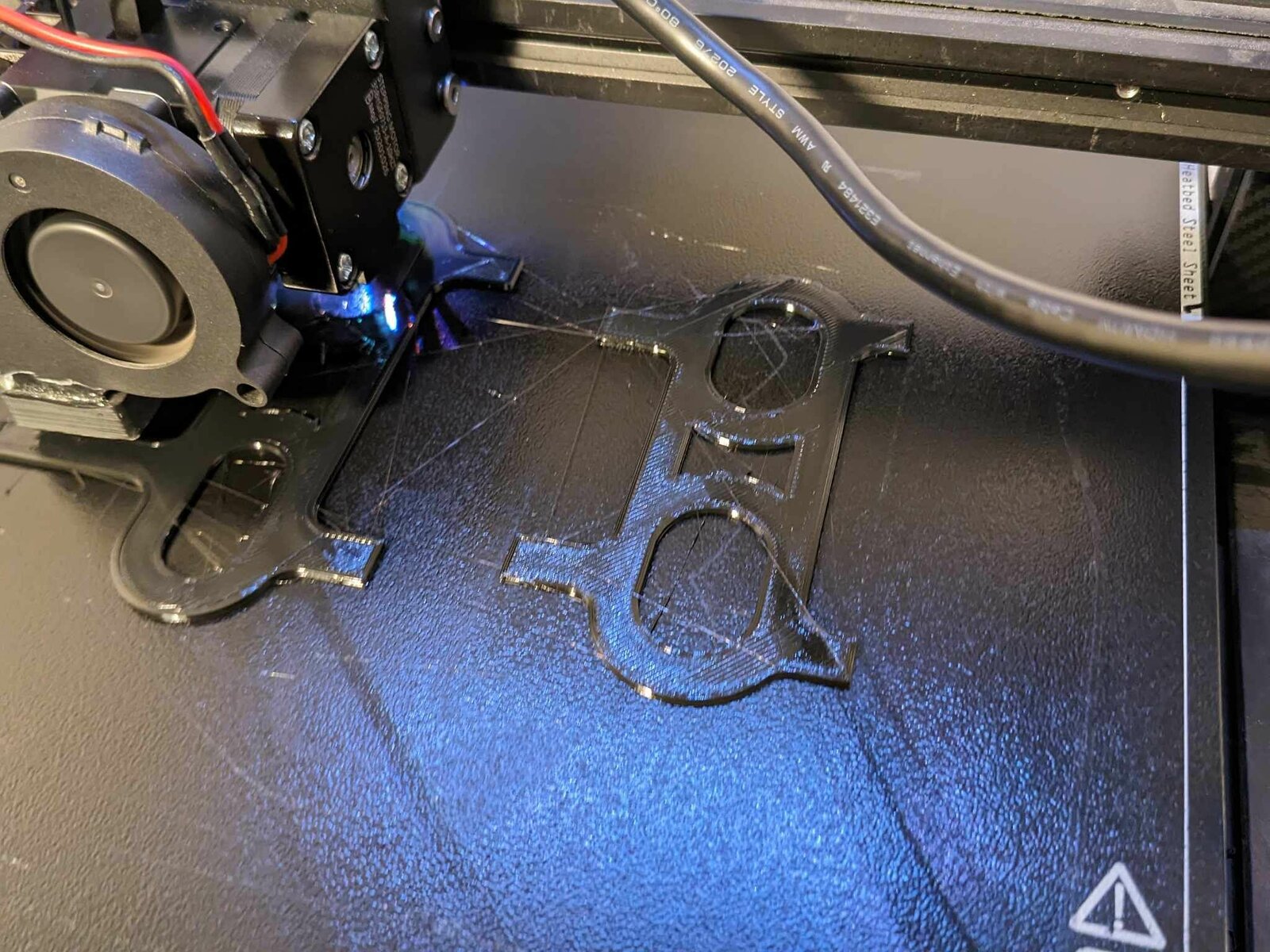

I am printing the long awaited Mojave bumper supports in TPU 9 hour print. For me if it fails it fails within the first couple layers and its well beyond that now. Maybe this old slow printer will have a new task and that is doing what it does best. Print things slowly but surely.

This is a big deal to me so its definitely a highlight in my 3D printing endeavor. I've always been annoyed not being able to print in TPU. I hope I cant get it down pat, and this is why its being mentioned in this thread.

Live print: "rotate button in lower right"

https://app.obico.io/printers/share_token/2eedee14ee843f962af772cfe5e9360e2f5b/

I wont go backwards only forwards. I have done a lot throughout the years of printing but who cares.... right... On with the thread...

So i've only tried TPU a couple times, always with failure @Dutch helped me understand what google literally would not tell me at all. It's 100% about speed. I'd like to elaborate my findings on that. With that knowledge I had a successful print, got cocky and ramped speed up to high and got failures.

A few hours ago I set everything on my BIQU BX back to 20mm/s, upped the heat to the hot-end some, and tried TPU again. My N4M is busy and cant be bothered lol....

So far so good. And for me the issue with printing at a faster speed is with extrusion. The filament is so flimsy that if I extrude to fast my "pullies with teeth" (i'm sure they have a name) that grab the filament strip the filament and then just cause it to jam and wad up above the hotend. I'm assuming this is everyone's issue with fast extrusion of TPU but I have only really successfully done this on 1 printer that it seems no body but me has, aside from a ton of people that upgrade their ender's with bigtree tech boards and extruders so they are basically BIQU's

I am printing the long awaited Mojave bumper supports in TPU 9 hour print. For me if it fails it fails within the first couple layers and its well beyond that now. Maybe this old slow printer will have a new task and that is doing what it does best. Print things slowly but surely.

This is a big deal to me so its definitely a highlight in my 3D printing endeavor. I've always been annoyed not being able to print in TPU. I hope I cant get it down pat, and this is why its being mentioned in this thread.

Live print: "rotate button in lower right"

https://app.obico.io/printers/share_token/2eedee14ee843f962af772cfe5e9360e2f5b/

Last edited: