Dan B.

Area man

Lifetime Premium!

Premium Member

ArrmaForum Fan

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,400

- Reaction score

- 17,230

- Location

- Southern Vermont

- Arrma RC's

- Fireteam

- Granite

- Limitless

- Mojave EXB

- Notorious

- Outcast 6s

- Typhon 6s

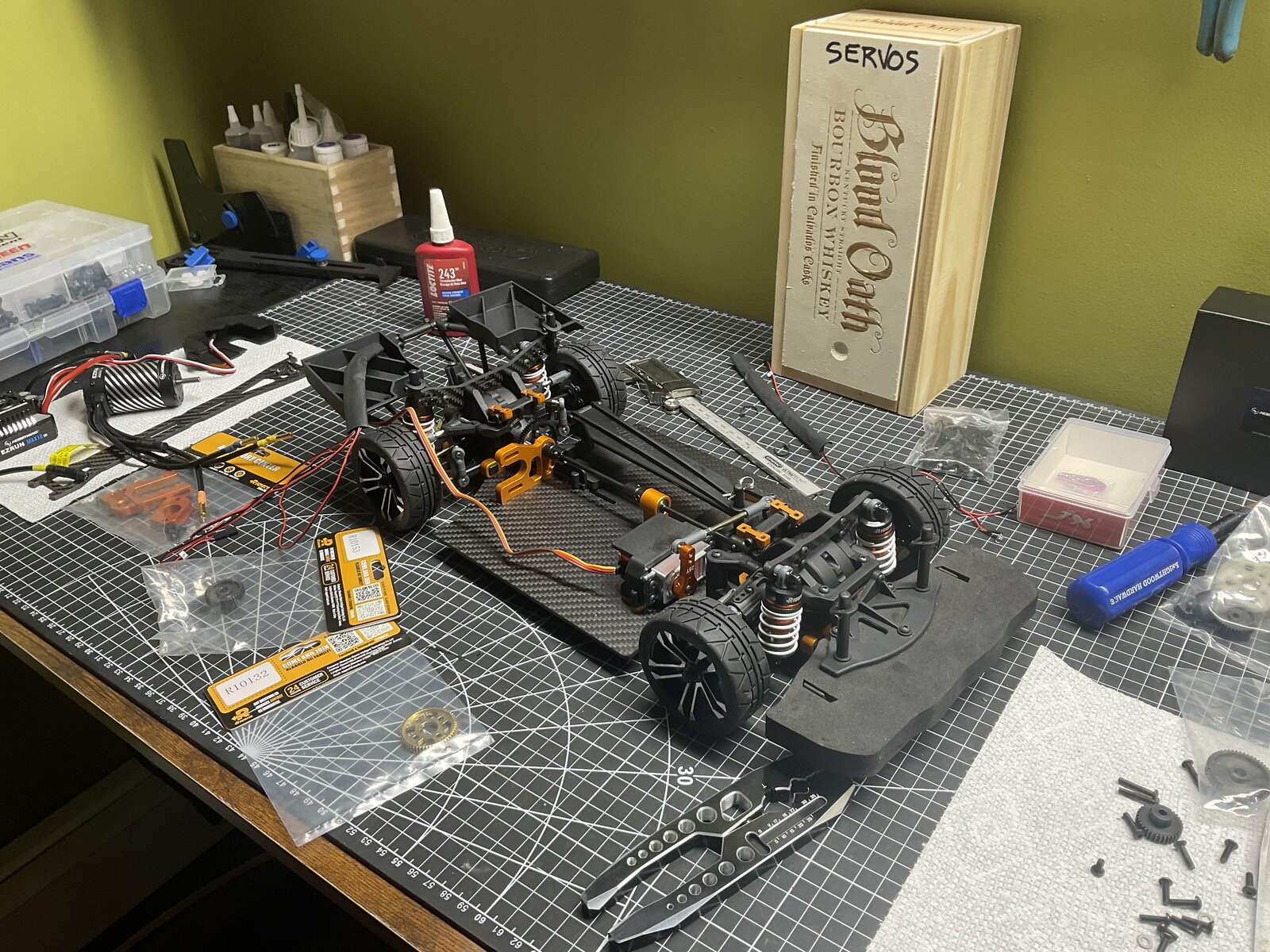

I finally got out the first of two AK917’s to build. Overall I’m really pleased and impressed with most of the car, but those guys need to get it together with QC on their spare parts orders. I’m using an HW Max10 G2 setup, so I ordered a variety of Rlaarlo steel pinions for 5mm shafts. One was mislabeled and was one of the smaller shaft size pinions. And every pinion I ordered came with grub screws that were too small, which is a PITA. It almost depleted my supply of grub screws, I’ll have to order more.

Started removing the motor mount to replace with their sliding, top adjustable mount.

None of the grub screws seemed to be loctited on the center shafts or drive cup. Also, if you’re building one of these, when I pulled them apart they were practically dripping with machine oil from the carrier bearings. I removed and cleaned the whole center drivetrain, put the well oiled bearings back, and loctited everything. I noticed when I got out the motor plate that one of the top threaded screw holes for the adjuster screws was machined off-center and the cut thread reliefs are peeking through the aluminum! I did check it, and it’s still very close to center and threads in securely so I’m going to use it.

I clocked the motor on the sliding mount to dry fit it. I put the pinion on it and the bore in the center of the plate is too small to allow the pinion to rotate because the goddamned grub screw rubs on the bore. The grub screw can’t be exposed more than 0.5mm when tight. Seriously? Very freaking disappointing. These are Rlaarlo pinions and motor mount, and they don’t play well with one another? I had to take a ridiculous amount of material out of the bore to clearance it. I know a lot of you guys used the Hobao mounts, and in hindsight I would have.

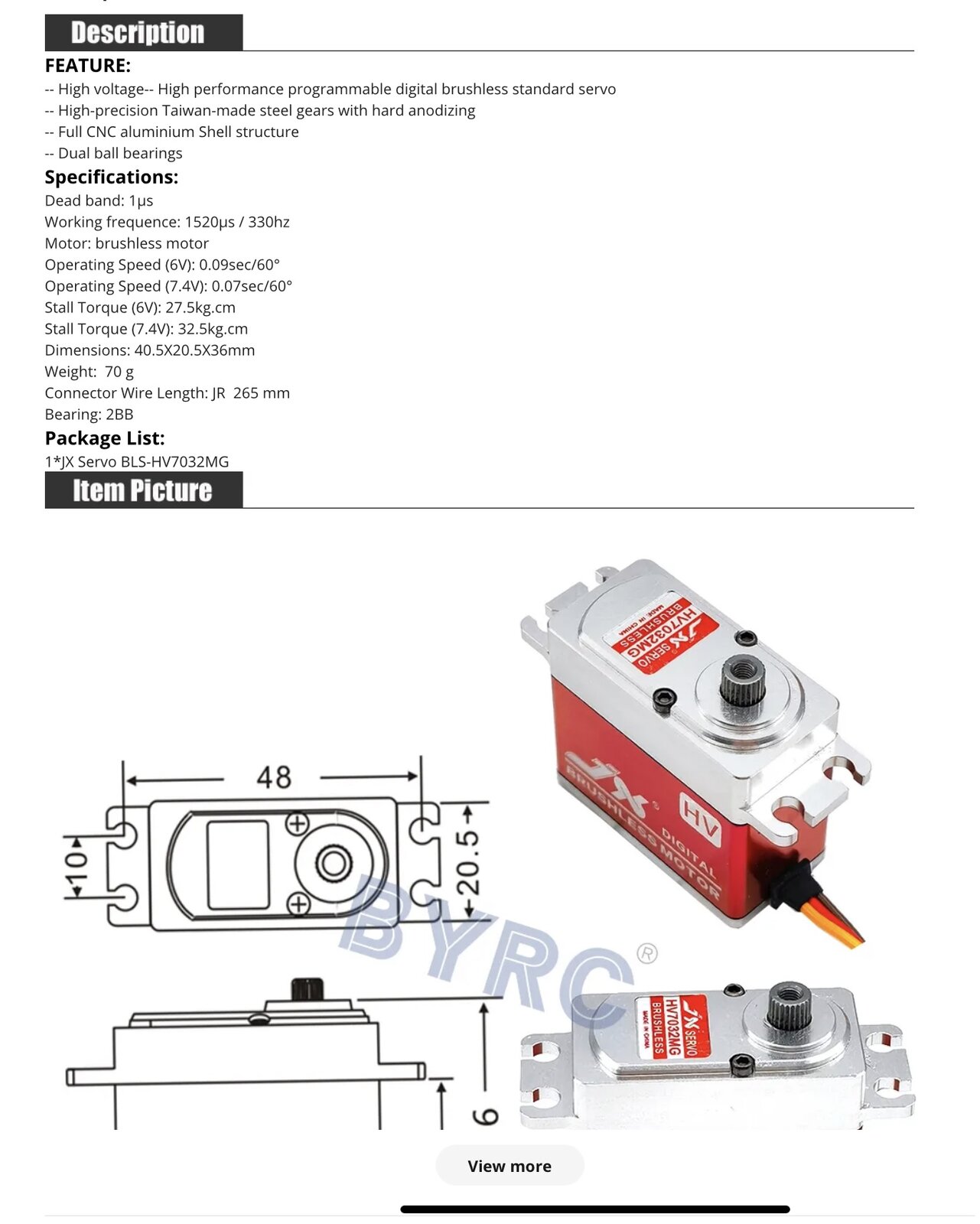

I used the factory servo mount and put in a $35.00 Ali sourced JX servo. It seems like a quality piece, nicely machined cases anyway. If the specs of the servo are even fairly close to stated it should be great for this tiny light car and it seems to center well, too.

For Gods sake, don’t tell John. I think this is the first car I’ve built in years without a ProModeler servo in it.

I’ll be fitting a small receiver box somewhere.

Overall I really like the car, and the quality of pretty much the whole thing is very impressive for the price. Dude, $168.00 for a nice carbon roller?!?!

Rlaarlo needs to get their own parts incompatibility issues resolved though, it was a shame to have to overcome so much dumb sh*t in the first five minutes of the build.

I‘ll update this in a day or two.

Started removing the motor mount to replace with their sliding, top adjustable mount.

None of the grub screws seemed to be loctited on the center shafts or drive cup. Also, if you’re building one of these, when I pulled them apart they were practically dripping with machine oil from the carrier bearings. I removed and cleaned the whole center drivetrain, put the well oiled bearings back, and loctited everything. I noticed when I got out the motor plate that one of the top threaded screw holes for the adjuster screws was machined off-center and the cut thread reliefs are peeking through the aluminum! I did check it, and it’s still very close to center and threads in securely so I’m going to use it.

I clocked the motor on the sliding mount to dry fit it. I put the pinion on it and the bore in the center of the plate is too small to allow the pinion to rotate because the goddamned grub screw rubs on the bore. The grub screw can’t be exposed more than 0.5mm when tight. Seriously? Very freaking disappointing. These are Rlaarlo pinions and motor mount, and they don’t play well with one another? I had to take a ridiculous amount of material out of the bore to clearance it. I know a lot of you guys used the Hobao mounts, and in hindsight I would have.

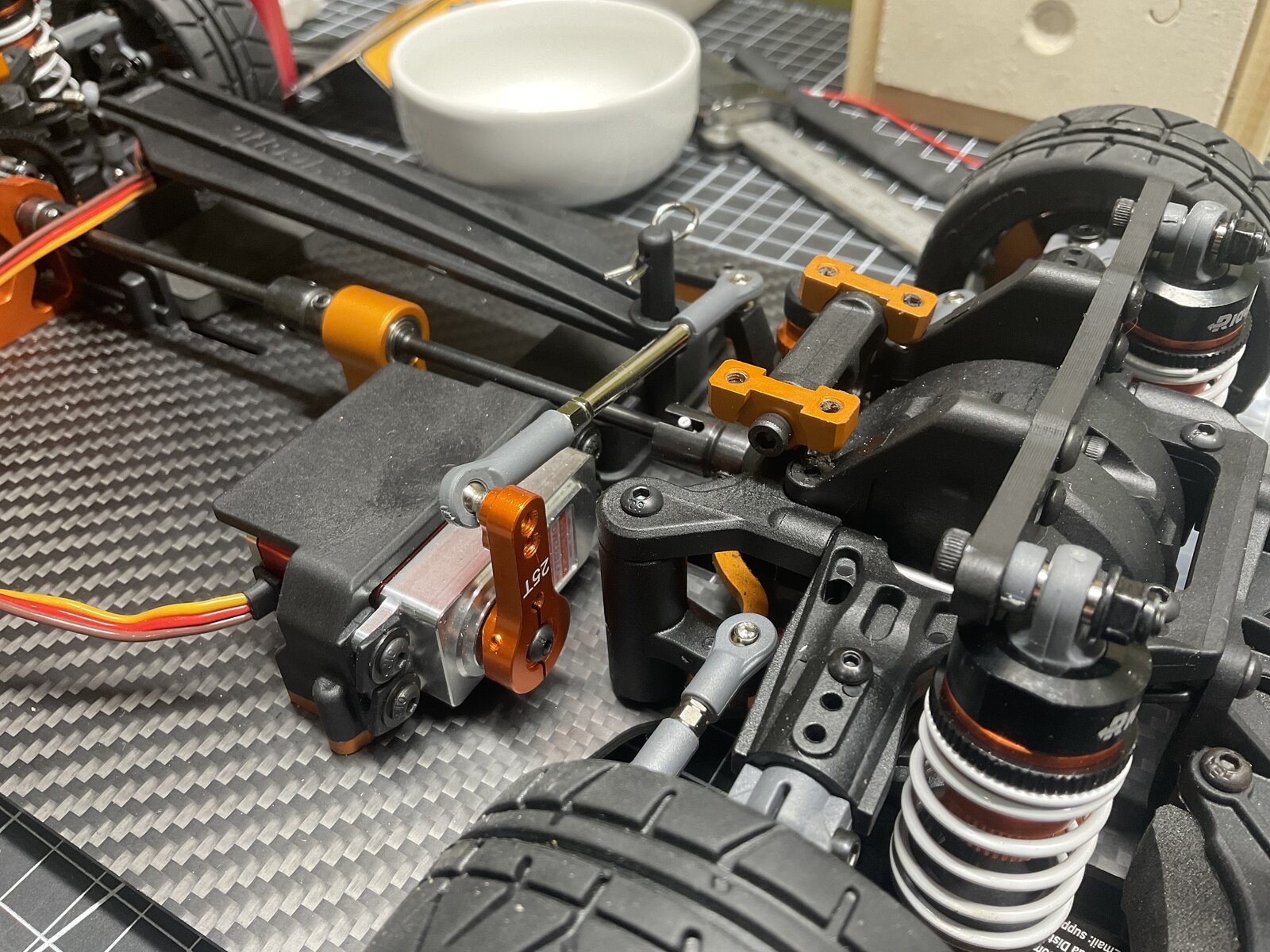

I used the factory servo mount and put in a $35.00 Ali sourced JX servo. It seems like a quality piece, nicely machined cases anyway. If the specs of the servo are even fairly close to stated it should be great for this tiny light car and it seems to center well, too.

For Gods sake, don’t tell John. I think this is the first car I’ve built in years without a ProModeler servo in it.

I’ll be fitting a small receiver box somewhere.

Overall I really like the car, and the quality of pretty much the whole thing is very impressive for the price. Dude, $168.00 for a nice carbon roller?!?!

Rlaarlo needs to get their own parts incompatibility issues resolved though, it was a shame to have to overcome so much dumb sh*t in the first five minutes of the build.

I‘ll update this in a day or two.