Dan B.

Area man

Lifetime Premium!

Premium Member

ArrmaForum Fan

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 6,390

- Reaction score

- 17,199

- Location

- Southern Vermont

- Arrma RC's

- Fireteam

- Granite

- Limitless

- Mojave EXB

- Notorious

- Outcast 6s

- Typhon 6s

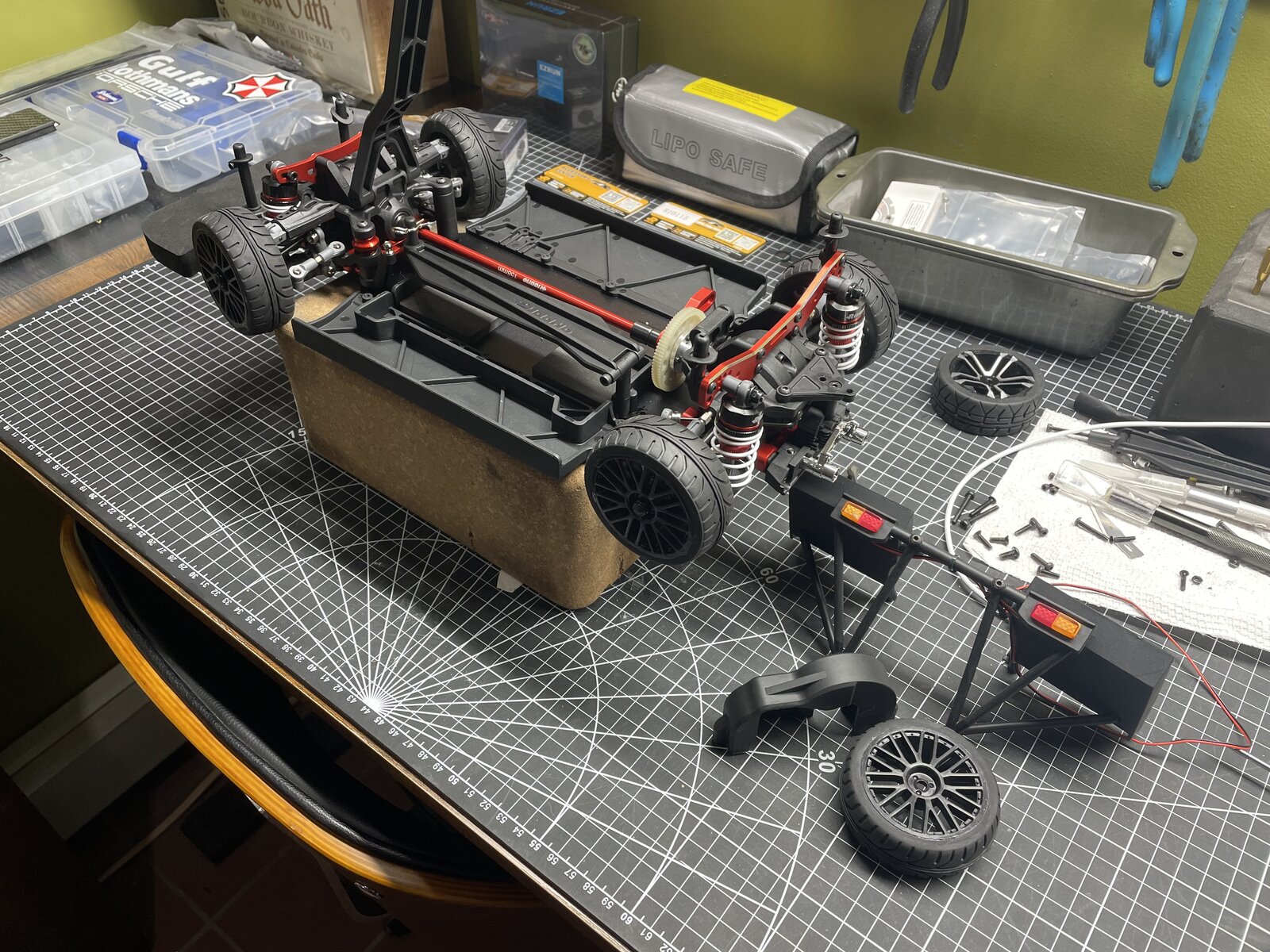

Having just finished my first ever Rlaarlo (https://www.arrmaforum.com/threads/rlaarlo-ak917-carbon-roller-build.67014/ ) I figured I’d just go ahead and build the next one. The first one was a carbon roller, this one is their cheaper aluminum roller. And what a difference there is! This one doesn’t come with nearly the amount of hop-up parts, and actually looks pretty naked by comparison.

I put it on my bench and started tearing it down. The whole tail, wing support, and lighting was removed, and none of that will be going back on.

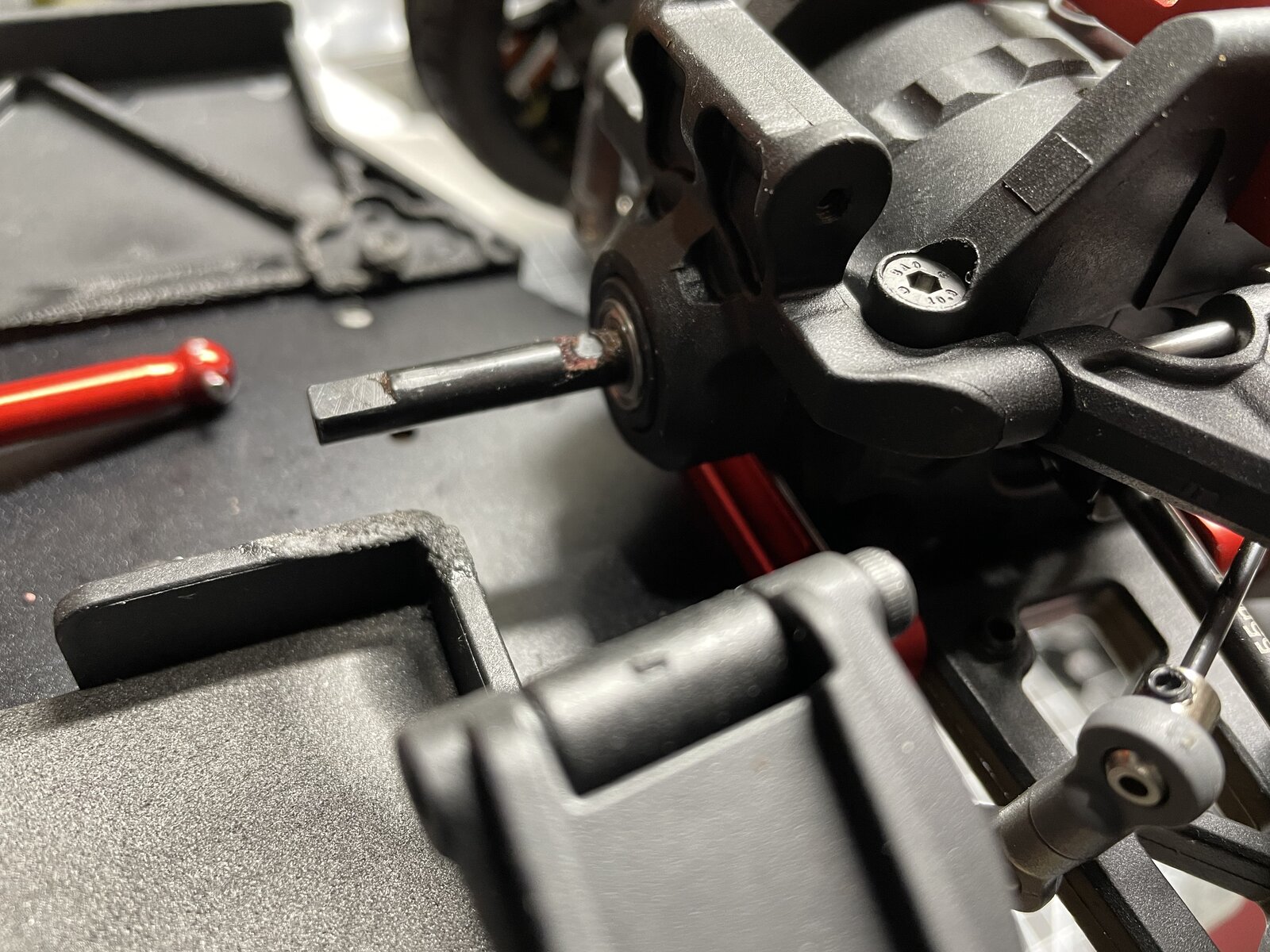

One of my first planned upgrades was to install the center driveshaft carrier bearing, which I had ordered when I got the car. Unfortunately, I wasn’t really paying attention and never noticed that this one has a single, solid center shaft and not the two piece arrangement of the carbon roller. I ordered the two center shafts from the Carbon car yesterday and I’ll install them when they arrive. Meanwhile, back at the ranch, while disassembling things I was stymied as to why the drive cups weren’t coming off and was wondering if they had multiple set screws I was missing. Nope. I finally heated the heck out of them and got them pulled only to discover that during manufacturing the shafts and the bores had been bathed in RED thread locker! After I got them pulled and cleaned there was literally a mound of powdered threadlocker under each cup. In the picture you can see the goopy stuff on the shaft, and even on the surface of the bearing. I’m surprised they still spun. The weird thing is, when I built the carbon roller there was not only zero threadlocker used in the middle anywhere, but the shafts and cups and pins were coated with machine oil that apparently ran out of the bearings. Everything had to get a solvent dip before I could even reassemble them and apply loctite.

I’ll be installing the sliding aluminum motor mount, the two piece center shafts with bearing carrier, and not really much else for upgrades until I start breaking things.

Finally, the intended purpose of this car will be all new to me. I’ll be building this for use on an indoor carpet track road course at a LHS near me. I’ve no experience here whatsoever, so during the course of the build I would really appreciate any and all feedback that any of you experienced carpet guys could give me. I’m quite sure I’ll be making multiple mistakes during the build and setup related to making a decent carpet car. TIA, peeps.

I put it on my bench and started tearing it down. The whole tail, wing support, and lighting was removed, and none of that will be going back on.

One of my first planned upgrades was to install the center driveshaft carrier bearing, which I had ordered when I got the car. Unfortunately, I wasn’t really paying attention and never noticed that this one has a single, solid center shaft and not the two piece arrangement of the carbon roller. I ordered the two center shafts from the Carbon car yesterday and I’ll install them when they arrive. Meanwhile, back at the ranch, while disassembling things I was stymied as to why the drive cups weren’t coming off and was wondering if they had multiple set screws I was missing. Nope. I finally heated the heck out of them and got them pulled only to discover that during manufacturing the shafts and the bores had been bathed in RED thread locker! After I got them pulled and cleaned there was literally a mound of powdered threadlocker under each cup. In the picture you can see the goopy stuff on the shaft, and even on the surface of the bearing. I’m surprised they still spun. The weird thing is, when I built the carbon roller there was not only zero threadlocker used in the middle anywhere, but the shafts and cups and pins were coated with machine oil that apparently ran out of the bearings. Everything had to get a solvent dip before I could even reassemble them and apply loctite.

I’ll be installing the sliding aluminum motor mount, the two piece center shafts with bearing carrier, and not really much else for upgrades until I start breaking things.

Finally, the intended purpose of this car will be all new to me. I’ll be building this for use on an indoor carpet track road course at a LHS near me. I’ve no experience here whatsoever, so during the course of the build I would really appreciate any and all feedback that any of you experienced carpet guys could give me. I’m quite sure I’ll be making multiple mistakes during the build and setup related to making a decent carpet car. TIA, peeps.