MrTitanium

Speak softly and carry a big stick.

- Messages

- 2,841

- Reaction score

- 14,946

- Arrma RC's

- BigRock

- BigRock 4x4

- Granite Grom

- Kraton EXB

- Nero

- Infraction 4x4

Hey fellas @Dutch @Tex Koder @Camaroboy383 and other fellow 3d print enthusiasts.

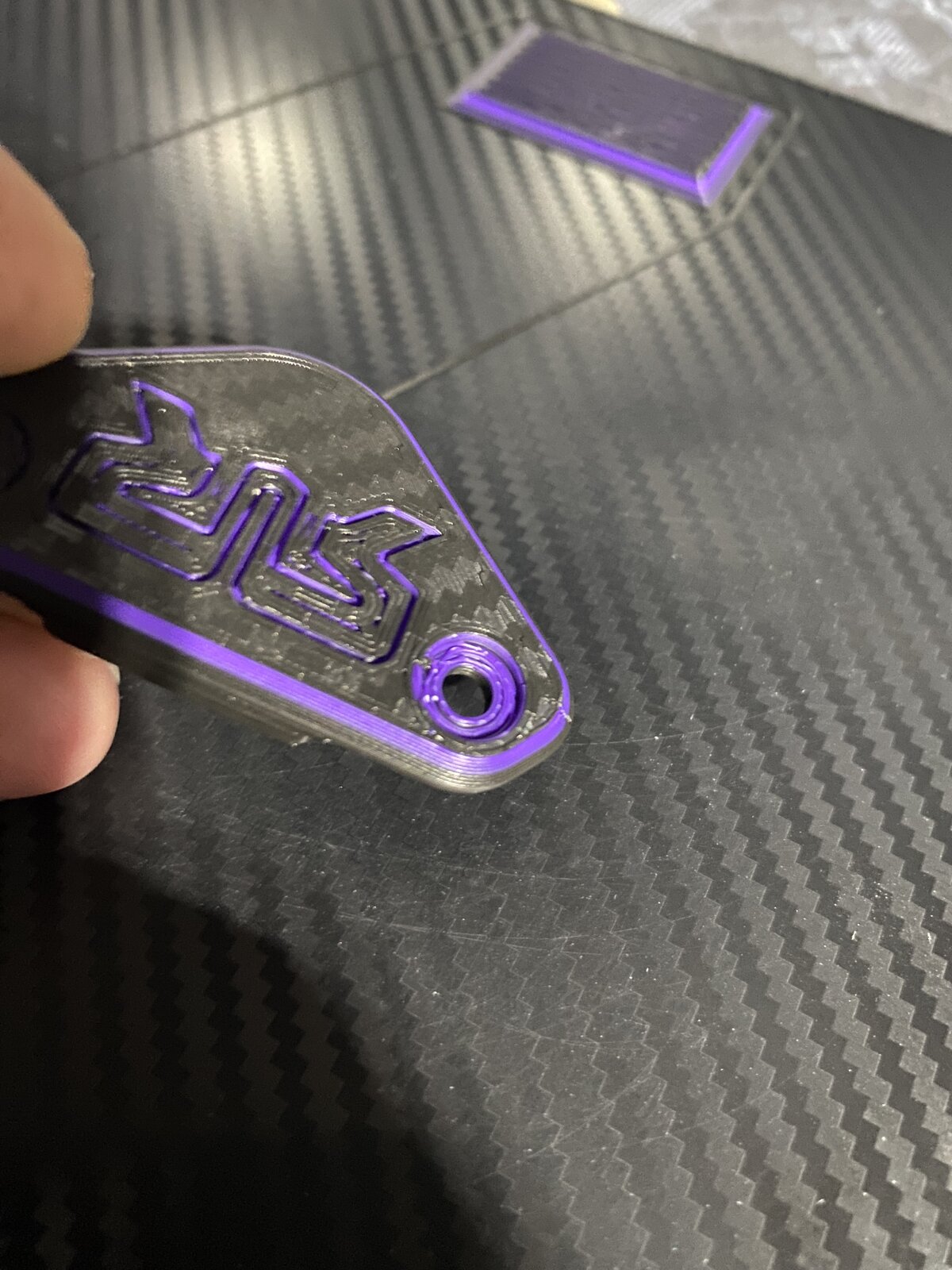

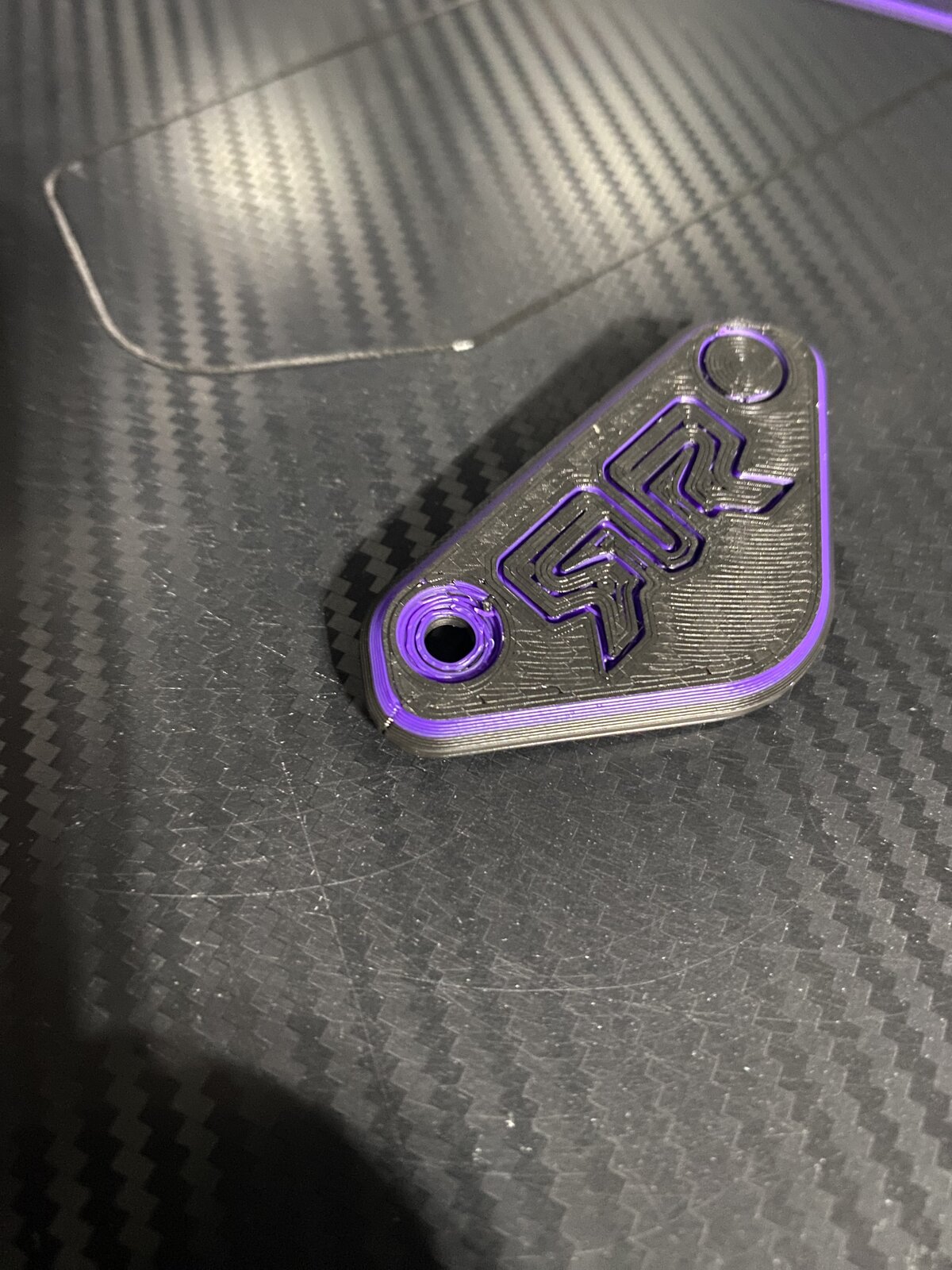

Printing this part face-down as I want that carbon fiber finish. I cannot get a solid finish where the bolt sits on the counterbore face.

I’ve tried many different Z top distances but cannot get the finish required.

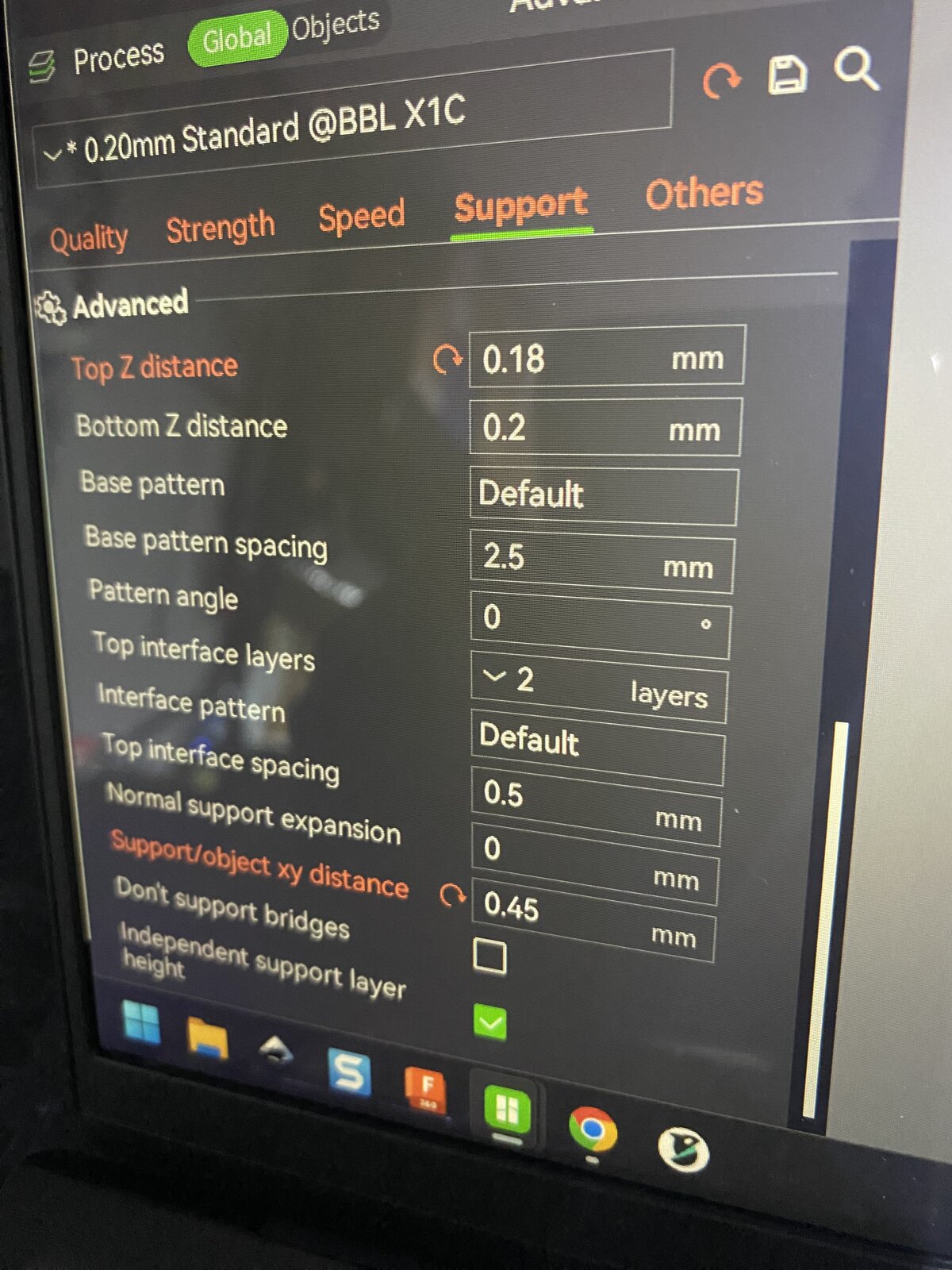

PLA with PLA top interface. Slicer is Bambu Studios/Orcaslicer for those wondering.

Printing this part face-down as I want that carbon fiber finish. I cannot get a solid finish where the bolt sits on the counterbore face.

I’ve tried many different Z top distances but cannot get the finish required.

PLA with PLA top interface. Slicer is Bambu Studios/Orcaslicer for those wondering.