Do you ever try to straighten out bent metal parts or just replace them with new? Case in point, I bent one of my front cvd driveshafts on my Outcast and debating if it's possible to straighten it enough to work properly again or if new ones would be best option.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Straightening out bent parts

- Thread starter abh16

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

I think it's a question of how bent it is. You can try straightening it out with a hammer and anvil (or other suitably hard and flat surface) or, the company T-Works makes a drive shaft correcting tool. https://www.rc-tworks.com/collections/frontpage/products/tt-065-driveshaft-correcting-tool

- Messages

- 1,155

- Reaction score

- 2,254

I use three bolts in a vice to straighten them as best I can, usually turns out okay. Chassis and shock towers get a vice and rubber hammer. Hard to get them completely straight, but it's a toy car and not a spacecraft, so whatever.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

I haven't really bent any shafts from my vehicle but I have straightened other metal rods with a satisfactory degree of success using a hammer and vise. Slow and steady wins the race. I've not used that tool myself but, from the looks of it, I think it would do a good job. I think the reasonable question is whether this happens often enough to make the $40 cost worthwhile.Very cool product. You ever tried straighten with any sucess?

I've already replaced all the drive shafts, CVDs and dog bones in my Infraction with carbon fiber and titanium shafts. I got paranoid after I saw a video where a guy killed a TP motor when the long rear shaft went v-shaped while he was driving and slammed into the can of the motor destroying it.

Where ya been brother!! Long time no see. I always wonder where you are and how you're doing about every two days. Good to see youI use three bolts in a vice to straighten them as best I can, usually turns out okay. Chassis and shock towers get a vice and rubber hammer. Hard to get them completely straight, but it's a toy car and not a spacecraft, so whatever.

And just for the record, my car is a spacecraft. I need my shafts to be straight

- Messages

- 1,155

- Reaction score

- 2,254

Very busy for the past month or so. Finally going to try to get the R/Cs out this coming weekend. Here's to hoping my shafts stay straight.

- Messages

- 4,298

- Reaction score

- 13,129

- Location

- North Liberty, IA

- Arrma RC's

- Infraction

- Kraton 6s

- Typhon 3s

- Typhon 6s

Here's to everyone's shafts staying straight & true!I think it's a question of how bent it is. You can try straightening it out with a hammer and anvil (or other suitably hard and flat surface) or, the company T-Works makes a drive shaft correcting tool. https://www.rc-tworks.com/collections/frontpage/products/tt-065-driveshaft-correcting-tool

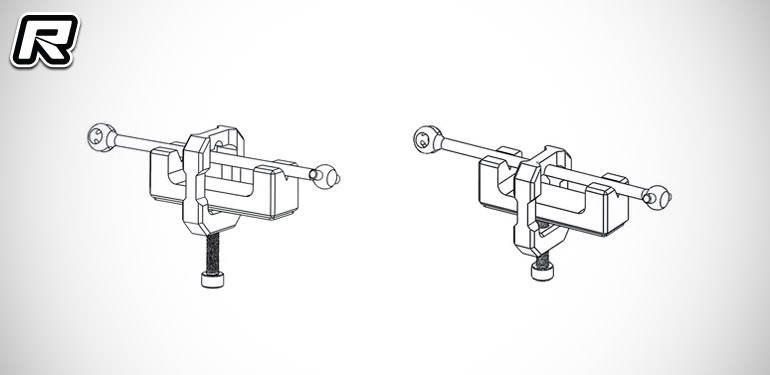

View attachment 246374

View attachment 246375

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

Yeah!! Just be careful with the hammer and anvil...Here's to everyone's shafts staying straight & true!

Hammer Down

I am serious, and don’t call me Shirley! 🙃

Premium Member

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 8,412

- Reaction score

- 21,642

- Arrma RC's

- Granite Grom

- Infraction

- Limitless

- Kraton 8S

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Outcast 8s

- Infraction 4x4

Hammer those puppy’s!

- Messages

- 13,021

- Reaction score

- 12,456

- Location

- Southeast Louisiana

- Arrma RC's

- BigRock 4x4

- Granite

- Kraton 6s

- Kraton 4s

- Outcast 4s

- Outcast 6s

- Vorteks

- Voltage

You can hammer your parts back but they will never be 100% straight which is ok but you can get them pretty close. The more they bend back and forth will cause metal fatigue and will eventually get weaker to a point of just replacing the part, case in point are stock Arrma 6S shock towers.

I should have tried that with those bent scorched shaftsI think it's a question of how bent it is. You can try straightening it out with a hammer and anvil (or other suitably hard and flat surface) or, the company T-Works makes a drive shaft correcting tool. https://www.rc-tworks.com/collections/frontpage/products/tt-065-driveshaft-correcting-tool

View attachment 246374

View attachment 246375

I only started replacing cvd and dogbone pins recently and haven’t tried to revive bend shafts.

I like to fix things, but I wonder if you can get it done properly and I think I would not want the risk of any remaining oscillation putting additional stress on the diffs and the already weak inner wheel bearings?

I like to fix things, but I wonder if you can get it done properly and I think I would not want the risk of any remaining oscillation putting additional stress on the diffs and the already weak inner wheel bearings?

- Messages

- 5,364

- Reaction score

- 8,339

- Arrma RC's

- Felony

- Kraton EXB

- Senton 3s

Just had HH send me a bunch for free, sick of their sheet!!I only started replacing cvd and dogbone pins recently and haven’t tried to revive bend shafts.

I like to fix things, but I wonder if you can get it done properly and I think I would not want the risk of any remaining oscillation putting additional stress on the diffs and the already weak inner wheel bearings?

Prolly wouldn't do the "bend it back" trick!!

Hector_Fisher

Very Active Member

^ this.You can hammer your parts back but they will never be 100% straight which is ok but you can get them pretty close. The more they bend back and forth will cause metal fatigue and will eventually get weaker to a point of just replacing the part, case in point are stock Arrma 6S shock towers.

Steel takes to "cold working" better than aluminum. If alu shock towers are bent, i'd say you maybe have one "straightening" to use and that's it, but even at that point you're already going to see pretty noticeable diminishing results. Shock tower strength would be suspect. Steel shafts could likely be bent back multiple times unless the bends are very severe, the biggest draw back being they likely won't be perfectly straight when you bend them back. All good in the end though since 1) likely most of us are driving our bashing RCs around with slightly bent driveshafts anyway, and 2) if it doesn't impact driving experience or cause excessive vibrations in the truck (which could decrease bearing life and loosen screws) then a slightly bent driveshaft probably doesn't matter too much.

IE, i'd totally give straightening your driveshafts a try. I can't really see a "worst case" here.

- Messages

- 6,177

- Reaction score

- 9,045

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

This method described by @Mr.Duke works really well.

I use hot glue to hold the bolts in place and it's easy to pull off when I'm done.

I use hot glue to hold the bolts in place and it's easy to pull off when I'm done.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,766

- Reaction score

- 42,274

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

All you need is 3 bolts and a vice. https://www.arrmaforum.com/threads/how-to-straighten-bent-dog-bones-driveshafts.19145/#post-259686

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,766

- Reaction score

- 42,274

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

MIP makes thicker ones.I bend em back in a vice typically. I'm a light basher I guess, haven't bent any Arrma or TC driveshafts enough to even bother straightening..Tekno is a different story, every drveshaft (CVD)on my mt410 is bent and several have been straightened a couple times over.

The Tekno shafts weren't designed for bashing but rather for racing so, definitely not picking on Tekno by any means.MIP makes thicker ones.

If ever I go to 6s in the mt410, it would surely need something thicker such as the MIP you suggested, or M2C, or even the Arrma/Tekno custom build..Thanks

I like keeping the mt410 light, just better that way IMO.

Hector_Fisher

Very Active Member

I noticed when building the SCT, the shafts were even thinner!The Tekno shafts weren't designed for bashing but rather for racing so, definitely not picking on Tekno by any means.

If ever I go to 6s in the mt410, it would surely need something thicker such as the MIP you suggested, or M2C, or even the Arrma/Tekno custom build..Thanks

I like keeping the mt410 light, just better that way IMO.

I mean, like you said it does make sense for a racing aspect. I'll be running 6s on my MT410 eventually (with a delicate trigger finger), i'll let you know if I have any issues. IIRC though, most bent driveshafts come from hard landings after big jumps, not necessarily 6s power.

Similar threads

- Replies

- 4

- Views

- 200