Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new Kraton 6s upgrade, repair, and build log. Aluminum, T-Bone, RPM, and more.

- Thread starter Custnam

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

- Thread starter

- #22

OK. Just posting another update. Im about 95% done at this point. Just finished installing all 3 new HR diff cups with 60/200/30. All thats left now is my T-Bone rear bumper, T-Bone chassis skid, and an aluminum center diff support. I really love hows it come out. All the red aluminum looks awesome. Makes me want to buy another 6s something and do all blue this time!

List so far:

1) Armor werks Aluminum servo mount red INSTALLED

2) Hexfly HX3225 25kg servo INSTALLED

3) Flysky FS-GT5 Receiver INSTALLED

4) Aluminum Rear Lower Suspension Mount red INSTALLED

5) Aluminum Rear Chassis brace red INSTALLED

6) Aluminum Front Chassis brace red INSTALLED

7) Aluminum Front Lower Arm Suspension Mount red INSTALLED

8) Aluminum Front Upper Arms Rear Bulk Mount red INSTALLED

9) Aluminum Center Diff Mount red ORDERED

10) Arrma AR320366 Wheelie Bar Set INSTALLED

11) RPM 81472 Front Bumper INSTALLED

12) T-Bone 10045 V3 Chassis Skid ORDERED

13) T-Bone 10018 Rear Basher Bumper ORDERED

14) TRB RC Sealed Bearings for Steering INSTALLED

15) Hot Racing aluminum diff cups INSTALLED (60F/200C/30R)

16) Dusty Motors shock covers INSTALLED

List so far:

1) Armor werks Aluminum servo mount red INSTALLED

2) Hexfly HX3225 25kg servo INSTALLED

3) Flysky FS-GT5 Receiver INSTALLED

4) Aluminum Rear Lower Suspension Mount red INSTALLED

5) Aluminum Rear Chassis brace red INSTALLED

6) Aluminum Front Chassis brace red INSTALLED

7) Aluminum Front Lower Arm Suspension Mount red INSTALLED

8) Aluminum Front Upper Arms Rear Bulk Mount red INSTALLED

9) Aluminum Center Diff Mount red ORDERED

10) Arrma AR320366 Wheelie Bar Set INSTALLED

11) RPM 81472 Front Bumper INSTALLED

12) T-Bone 10045 V3 Chassis Skid ORDERED

13) T-Bone 10018 Rear Basher Bumper ORDERED

14) TRB RC Sealed Bearings for Steering INSTALLED

15) Hot Racing aluminum diff cups INSTALLED (60F/200C/30R)

16) Dusty Motors shock covers INSTALLED

Last edited:

3d-rc.myshopify.com

Eat,sleep and breath Arrma

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 6,198

- Reaction score

- 11,381

- Location

- Michigan

- Arrma RC's

- BigRock 4x4

- Granite

- Infraction

- Kraton 8S

- Kraton 6s

- Notorious

- Senton 6s

- Senton 3s

Looking good there. She looks so purdy and clean.

- Thread starter

- #24

- Messages

- 4,248

- Reaction score

- 7,413

- Location

- SE PA

- Arrma RC's

- Kraton 8S

- Kraton 6s

- Mojave EXB

- Outcast 6s

- Talion

- Typhon 6s

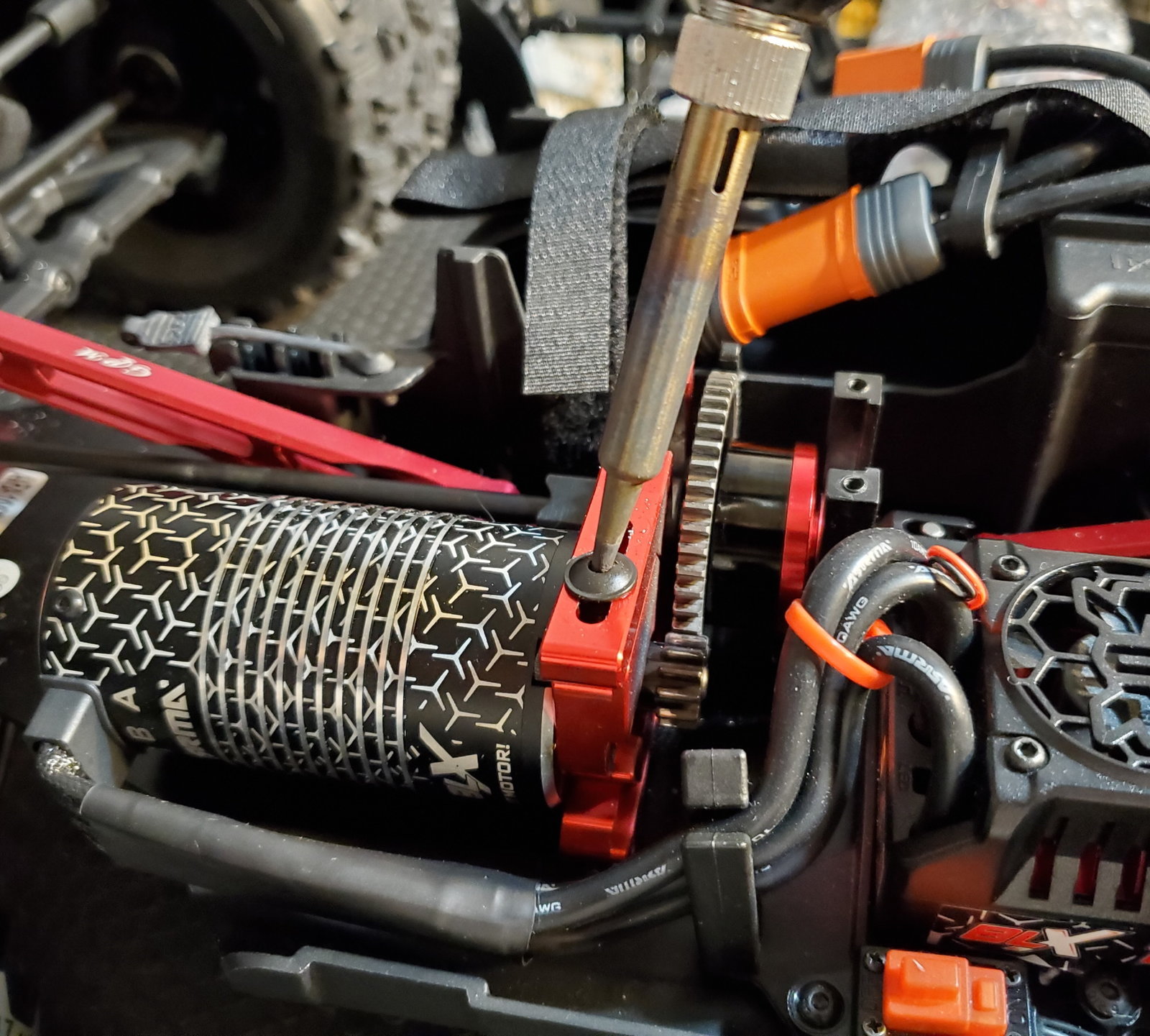

Answer to question in post 14. Forgive me if someone already answered...Set screw without threads. They did remember to put locktite on it thought

- Thread starter

- #26

Answer to question in post 14. Forgive me if someone already answered...Set screw without threads. They did remember to put locktite on it thought

You WIN! I laughed when I saw it.

- Thread starter

- #27

Just adding a couple more pics after finishing the body with Arrma Forum decals. I love the way it came out.

- Thread starter

- #28

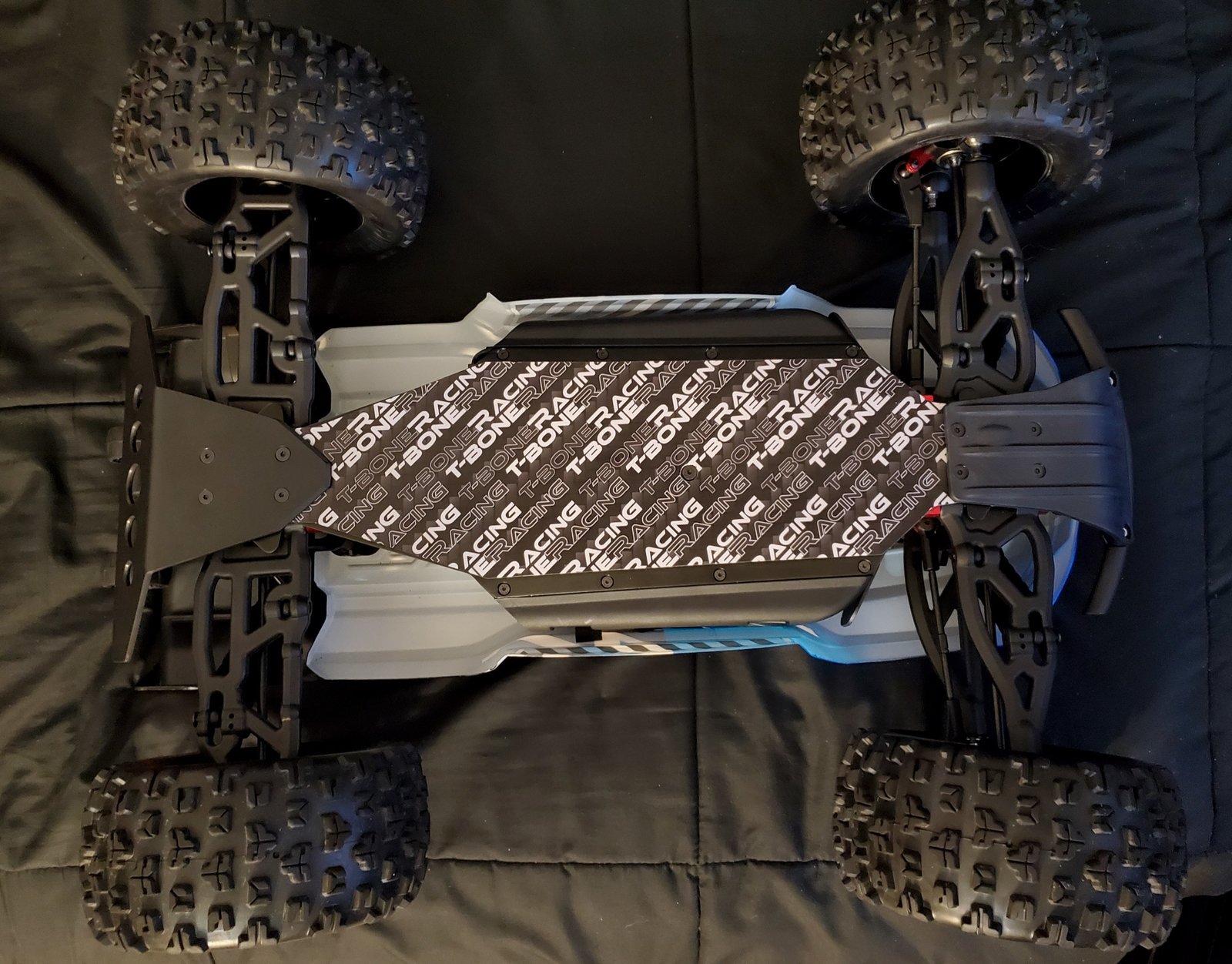

OK. The T-Bone stuff finally came and I installed the rear bumper and the chassis skid like I do on all my vehicles. But this time I decided to actually install the optional vinyl cover. It had to be fully cut out with all the holes, etc. but it came out awesome. While installing it I realized the skid isnt all that compatible with the stock Kraton bumper. It would have left a gap between the chassis and the skid for rocks, and other junk to get wedged in there. So thankfully I still had a brand new stock Typhon bumper and used that. Worked perfect. The skid also didnt have the hole in the middle countersunk like its suppose to be so I had to use a drill to fix that. No big deal. The bottom is a lot less plain now and has some style, not to mention even more protection!

Its basically done at this point with the small exception of an aluminum center diff mount still on the way. Overall I have to say the build has been fun, informative, and came out great. Now onto scratching, denting, scraping and breaking all that hard work!!

Its basically done at this point with the small exception of an aluminum center diff mount still on the way. Overall I have to say the build has been fun, informative, and came out great. Now onto scratching, denting, scraping and breaking all that hard work!!

Last edited:

- Thread starter

- #29

Decided to install 14 tooth pinions in my Kraton and Notorious and found 2 RR ones on Ebay for only $4.20 each. So bought them both. Just installed them and thanks to others suggesting soldering irons to loosen up thread lock it was an easy swap. Just pressed the tip on the iron into the screw head and waited about 30 seconds. Broke free with ease after that. Should be interesting to see the difference.

- Thread starter

- #30

Heres a quick video I took of how it runs now with the 14T RR pinion. I didnt expect much from 2 extra teeth, but WOW is it fast now. I don't even have enough room to get it to top speed properly. Driving one handed here so not exactly exciting.

- Thread starter

- #32

Nice dude. I run my Talion with a 15t and couldn't be happier.

Stock is 13T on that right? So you went up 2 teeth also? Any heat issues, are you running a motor fan?

Ralion

Member

- Messages

- 56

- Reaction score

- 106

- Arrma RC's

- Talion

- Typhon 6s

Yup the stock is 13. I tried a 16t when I first got it because a lot of people seem to use that. The 13t felt more hands on and in control ya know, I went down to 15t and never looked back. Temps seem fine. I don't have a temp gun or a fan but I can totally touch it for 10 seconds without burning myself so I'm sure it's within specs.

Stock is 13T on that right? So you went up 2 teeth also? Any heat issues, are you running a motor fan?

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,893

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I played around with gearing in my 6S Kraton. I settled with the 16T. 17 was too high for me with heat and all. 15 felt ok but under geared a bit yet. All Stock electrics. Just added two 25mm fans to the motor.

SrC

RC is a lifestyle choice

Lifetime Premium!

Premium Member

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 22,472

- Reaction score

- 30,893

- Location

- Queens, NYC

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton 6s

- Mojave

- Notorious

- Outcast 6s

- Typhon TLR

I always do tight figure eights with brand new rebuilt diffs for at least 5-10 mins or longer. A proper break-in leads to more durable diffs. Been doing this forever. Ball type diffs can break-in fine done on the bench. Gear type diffs need a load to break-in, hence driving figure eights is best. IMO.Yea I had a feeling it just needed to be broken in. I never checked the diffs on my Notorious prior to driving it so I didnt have that as a comparison. Im sure it will be perfect after a couple runs. I also noticed that it got worse depending on how tight the 4 main screws are that hold the upper half on. So that must be putting extra pressure on the shim which also causes the mesh to be tighter.

- Thread starter

- #36

Diffs are definitely quieter after a few runs. Not quite as smooth as my Notorious but its been run a lot more.

- Thread starter

- #38

Their called Dusty motors shock covers. Ebay item 392345564173Where did you get the shock covers? I can’t seem to find any

Siik_ap2

Active Member

- Messages

- 52

- Reaction score

- 46

- Arrma RC's

- Kraton 6s

So the Xmaxx sized ones will fit the kraton 6s?Their called Dusty motors shock covers. Ebay item 392345564173

- Thread starter

- #40

So the Xmaxx sized ones will fit the kraton 6s?

Yes. They just have them listed as X-Maxx because they are popular on that vehicle. They are cut to length strips and are stretchy. They would even fit my 4s Arrmas also if I cut them to that length. Pic added for reference.

Similar threads

- Replies

- 23

- Views

- 1K