2015GTRBE

Patrick Bateman ?

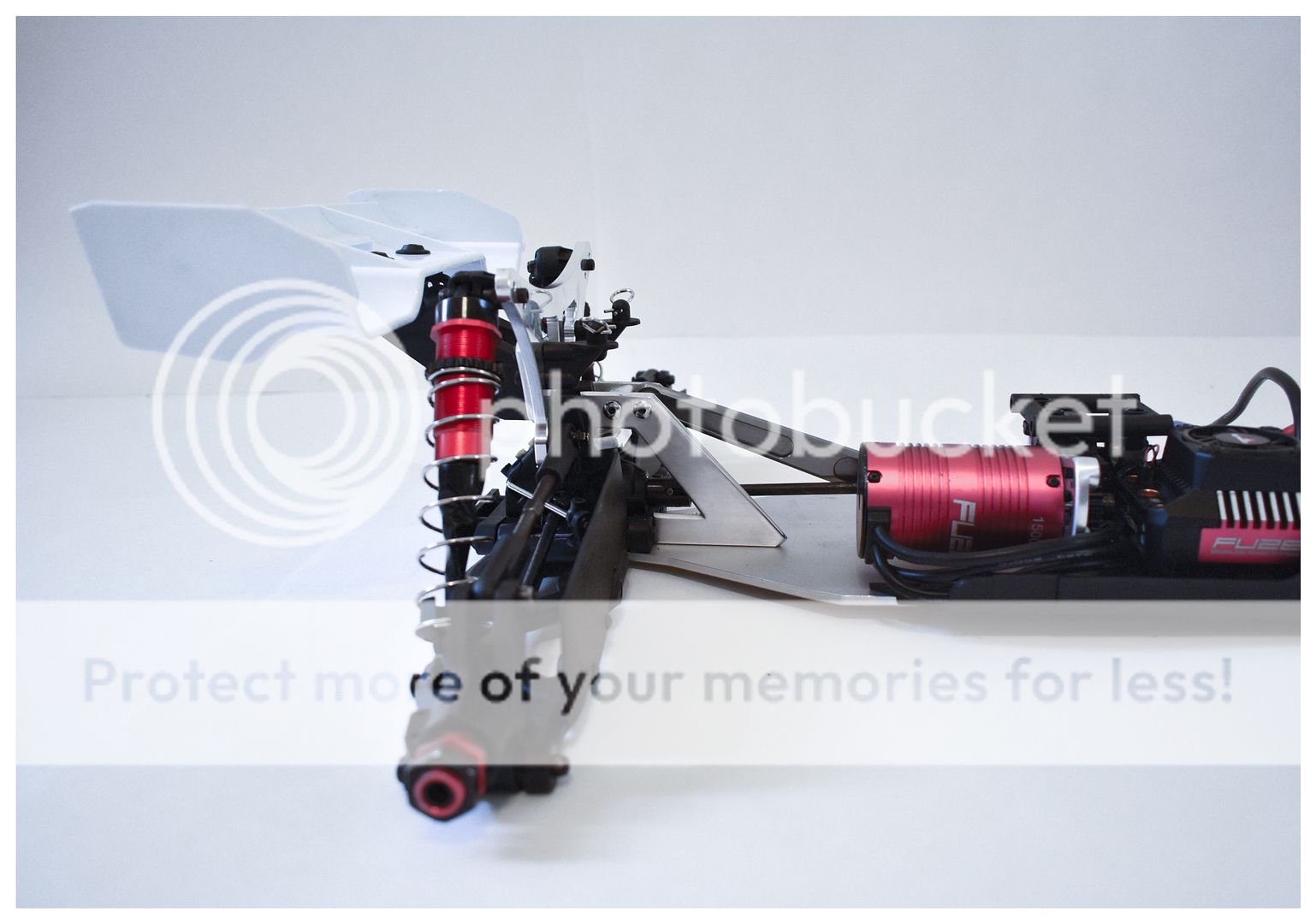

I got my Street Crushers in today!

Side note - The factory wheels were a PITA to get off! I was about to rip the whole A-Arm off!

Next up - Install Yeah Racing heatsink with fans.

If you have trouble getting factory wheels off (only Arrmas, it’s weird) you can use an automotive bearing puller. Ask how I figured that one out