- Messages

- 1,595

- Reaction score

- 3,387

- Location

- Bozeangeles

- Arrma RC's

- BigRock 4x4

- Kraton EXB

- Kraton 4s

- Notorious

- Senton 3s

- Typhon 6s

- Typhon 3s

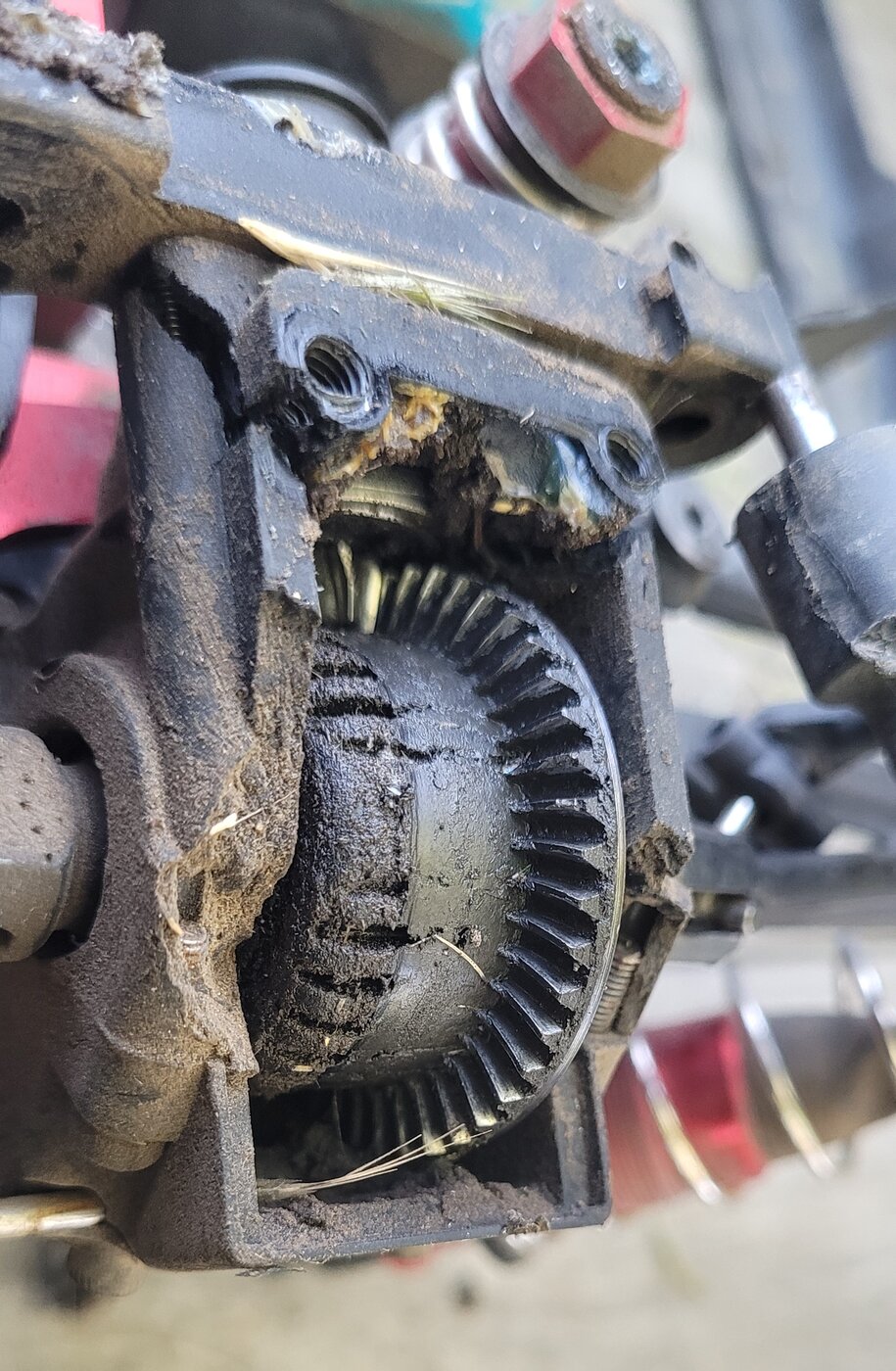

How'd I do?

Honestly, I was just driving along! I barely even sent it 100'! Cain't EVEN believe how fragile these exb's are!

Do you think I could flip the chassis upside down and reuse it?

Honestly, I was just driving along! I barely even sent it 100'! Cain't EVEN believe how fragile these exb's are!

Do you think I could flip the chassis upside down and reuse it?